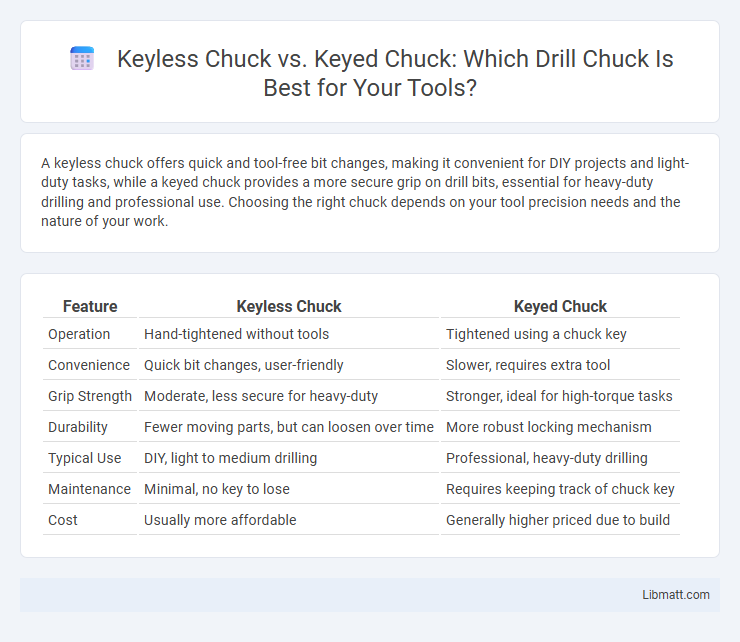

A keyless chuck offers quick and tool-free bit changes, making it convenient for DIY projects and light-duty tasks, while a keyed chuck provides a more secure grip on drill bits, essential for heavy-duty drilling and professional use. Choosing the right chuck depends on your tool precision needs and the nature of your work.

Table of Comparison

| Feature | Keyless Chuck | Keyed Chuck |

|---|---|---|

| Operation | Hand-tightened without tools | Tightened using a chuck key |

| Convenience | Quick bit changes, user-friendly | Slower, requires extra tool |

| Grip Strength | Moderate, less secure for heavy-duty | Stronger, ideal for high-torque tasks |

| Durability | Fewer moving parts, but can loosen over time | More robust locking mechanism |

| Typical Use | DIY, light to medium drilling | Professional, heavy-duty drilling |

| Maintenance | Minimal, no key to lose | Requires keeping track of chuck key |

| Cost | Usually more affordable | Generally higher priced due to build |

Introduction to Drill Chucks

Drill chucks serve as the gripping mechanism to hold drill bits securely during operation, with keyless and keyed chucks being the primary types. Keyless chucks allow quick, tool-free bit changes by hand tightening, making them ideal for convenience and frequent size adjustments. In contrast, keyed chucks use a toothed key to tighten the grip, offering superior torque and bit security for heavy-duty drilling tasks.

What is a Keyed Chuck?

A keyed chuck is a drill chuck that requires a key to tighten or loosen the grip on the drill bit, providing secure and precise bit holding. It offers enhanced torque transfer and prevents slippage during heavy-duty drilling tasks, making it ideal for professional use. The key engages with gear teeth on the chuck, allowing for uniform tightening around the bit.

What is a Keyless Chuck?

A keyless chuck is a drill chuck designed to tighten and loosen the drill bit by hand, eliminating the need for a separate key tool. This mechanism allows for quicker bit changes and enhanced convenience, especially useful in cordless and handheld drills. Your drilling efficiency improves with a keyless chuck by enabling swift bit swaps without interrupting workflow.

Keyed Chuck: Pros and Cons

Keyed chucks offer superior grip strength and better torque transmission for heavy-duty drilling tasks, making them ideal for work requiring precise bit stability. However, they require a chuck key for tightening and loosening, which can slow down bit changes and presents a risk of losing the key during operation. Their durability and secure bit retention make them favored in industrial and professional settings despite the added maintenance effort.

Keyless Chuck: Pros and Cons

Keyless chucks offer quick and convenient bit changes without the need for a separate key, enhancing efficiency in repetitive drilling tasks. They provide a secure grip for common applications but may not hold as tightly as keyed chucks when under heavy load or torque. Your choice depends on whether speed or maximum bit retention is more critical for your projects.

Speed and Convenience Comparison

Keyless chucks provide faster and more convenient drill bit changes by allowing you to tighten or loosen the bit with your hand, eliminating the need for a separate key tool. Keyed chucks require the use of a chuck key to securely tighten the bit, which can slow down the process and may cause inconvenience if the key is misplaced. Your choice between keyless and keyed chucks will impact how quickly you can adapt to different drilling tasks, emphasizing ease of use versus extra bit security.

Grip Strength and Security

Keyless chucks offer quick tool changes but generally provide less grip strength compared to keyed chucks, which use a gear mechanism to tighten the jaws more securely around the bit. For applications requiring maximum grip strength and enhanced security against slippage, keyed chucks are preferred due to their ability to maintain a firmer hold under heavy torque. You should choose a keyed chuck if reliable bit retention during intense drilling tasks is critical.

Suitability for Different Applications

Keyless chucks excel in applications requiring quick bit changes and frequent tool adjustments, making them ideal for DIY projects and light to medium-duty tasks. Keyed chucks provide a more secure grip on drill bits, making them suitable for heavy-duty drilling and professional use demanding high torque. Your choice depends on the balance between convenience and the level of grip required for the specific drilling application.

Maintenance and Longevity

Keyless chucks require less frequent maintenance since they do not have a key mechanism that can wear out or get lost, making them highly convenient for quick bit changes. Keyed chucks, while necessitating regular lubrication and occasional tightening of the key mechanism to ensure optimal performance, typically offer greater durability under heavy-duty use due to their robust design. Proper care, such as cleaning and lubrication, significantly extends the longevity of both chuck types, but keyed chucks often last longer in industrial environments thanks to their secure grip and mechanical resilience.

Which Chuck is Right for You?

Keyless chucks offer quick and easy bit changes without the need for a separate key, ideal for DIYers and frequent tool users seeking convenience and speed. Keyed chucks provide a more secure grip on drill bits, making them preferable for heavy-duty applications and professional users requiring maximum torque and reliability. Your choice depends on the balance between convenience and the level of torque control needed for your specific drilling tasks.

Keyless chuck vs keyed chuck Infographic

libmatt.com

libmatt.com