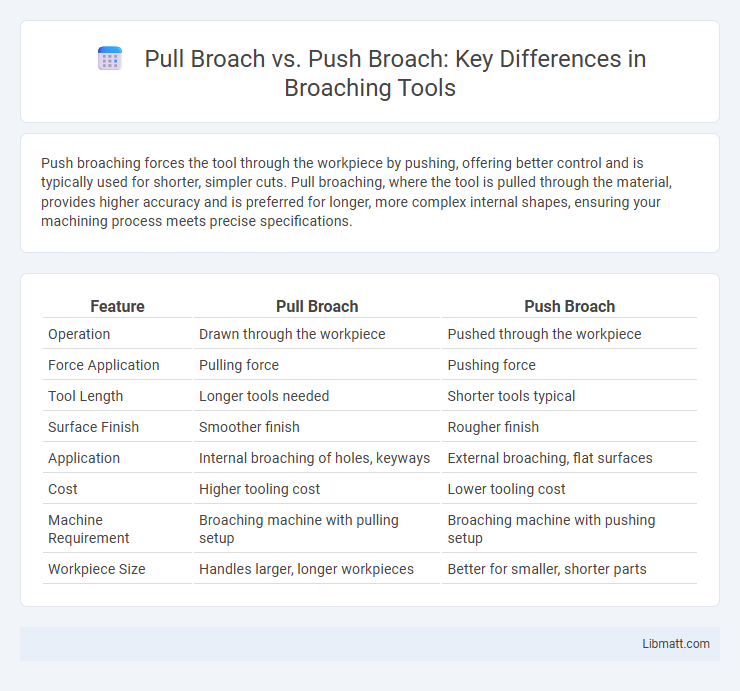

Push broaching forces the tool through the workpiece by pushing, offering better control and is typically used for shorter, simpler cuts. Pull broaching, where the tool is pulled through the material, provides higher accuracy and is preferred for longer, more complex internal shapes, ensuring your machining process meets precise specifications.

Table of Comparison

| Feature | Pull Broach | Push Broach |

|---|---|---|

| Operation | Drawn through the workpiece | Pushed through the workpiece |

| Force Application | Pulling force | Pushing force |

| Tool Length | Longer tools needed | Shorter tools typical |

| Surface Finish | Smoother finish | Rougher finish |

| Application | Internal broaching of holes, keyways | External broaching, flat surfaces |

| Cost | Higher tooling cost | Lower tooling cost |

| Machine Requirement | Broaching machine with pulling setup | Broaching machine with pushing setup |

| Workpiece Size | Handles larger, longer workpieces | Better for smaller, shorter parts |

Introduction to Broaching: Pull vs Push

Pull broaching involves the tool being pulled through the workpiece, enabling precise control and reduced friction, making it ideal for intricate internal shapes. Push broaching requires the tool to be pushed through, often used for simpler external profiles but may cause increased tool wear due to higher compressive forces. Understanding the differences helps you select the right broaching method for your machining needs, optimizing surface finish and production efficiency.

Understanding Pull Broaching

Pull broaching uses a tool that is drawn through the workpiece, creating precise internal shapes with consistent surface finishes and dimensional accuracy. This method reduces tool wear and minimizes the risk of tool breakage by relying on tensile forces rather than compressive forces. Pull broaching is particularly effective for smaller, more intricate components where fine detail and tight tolerances are required.

Exploring Push Broaching

Push broaching involves forcing the broach tool through the material to create precise internal shapes, offering efficient chip removal and reduced tooling wear compared to pull broaching. This method is often preferred for applications requiring higher production rates and the machining of harder materials, as the push action distributes cutting forces more evenly. Industries such as automotive and aerospace favor push broaching for its ability to deliver consistent dimensional accuracy and surface finish in complex internal profiles.

Key Differences Between Pull and Push Broach

Pull broaches operate by pulling the tool through the workpiece, providing greater control and precision for intricate shapes, while push broaches are pushed through, often suited for simpler profiles and higher production rates. Pull broaching typically requires less force, reducing tool wear and improving surface finish, whereas push broaching can handle tougher materials but may result in faster tool degradation. Your choice between pull and push broaches depends on the complexity of the part, material hardness, and desired accuracy.

Advantages of Pull Broaching

Pull broaching offers greater precision and smoother finishes compared to push broaching, due to the controlled tension applied throughout the cut. It reduces workpiece distortion and tool wear, enhancing tool life and consistency in complex shapes. Higher reliability and suitability for harder materials make pull broaching ideal for fine, intricate machining applications.

Benefits of Push Broaching

Push broaching offers precise control over cutting forces, resulting in smoother surface finishes and extended tool life. Its ability to maintain consistent alignment reduces the risk of workpiece deformation, making it ideal for complex or delicate materials. Your manufacturing process benefits from faster cycle times and improved accuracy compared to traditional pull broaching methods.

Common Applications: Pull vs Push Broach

Pull broaches are commonly used for precision finishing in applications such as keyways, splines, and small internal profiles where tight tolerance control is critical. Push broaches are preferred for larger, less delicate cuts like internal diameters and simple shapes, often in high-volume production environments due to their ability to handle heavier cuts. Understanding your specific machining requirements helps determine whether a pull broach or push broach provides optimal performance and surface finish quality.

Tool Design Considerations

Pull broach tool design prioritizes durability and alignment to withstand the tensile forces exerted during operation, with a focus on precise rake angles and chip evacuation paths to optimize cutting efficiency. Push broach tools require robust support structures and stepped tooth geometry to manage compressive forces and prevent tool deflection or jamming. Your choice between pull and push broaching tools should consider material properties, machine capabilities, and desired surface finish to achieve optimal performance.

Choosing the Right Broaching Method

Choosing the right broaching method depends on factors like workpiece size, shape, and required precision. Pull broaches are ideal for long, slender components and provide excellent surface finish, while push broaches are better suited for shorter parts and high-volume production. Considering tooling costs and machine capabilities helps optimize efficiency and manufacturing quality.

Summary and Recommendations

Pull broaches offer greater accuracy and surface finish due to controlled tension, making them ideal for precision machining of internal features. Push broaches are typically more cost-effective and suitable for softer materials or applications where surface finish is less critical. For your machining needs, choose pull broaching when precision and quality are paramount, while push broaching is recommended for simpler, high-volume production runs.

Pull broach vs push broach Infographic

libmatt.com

libmatt.com