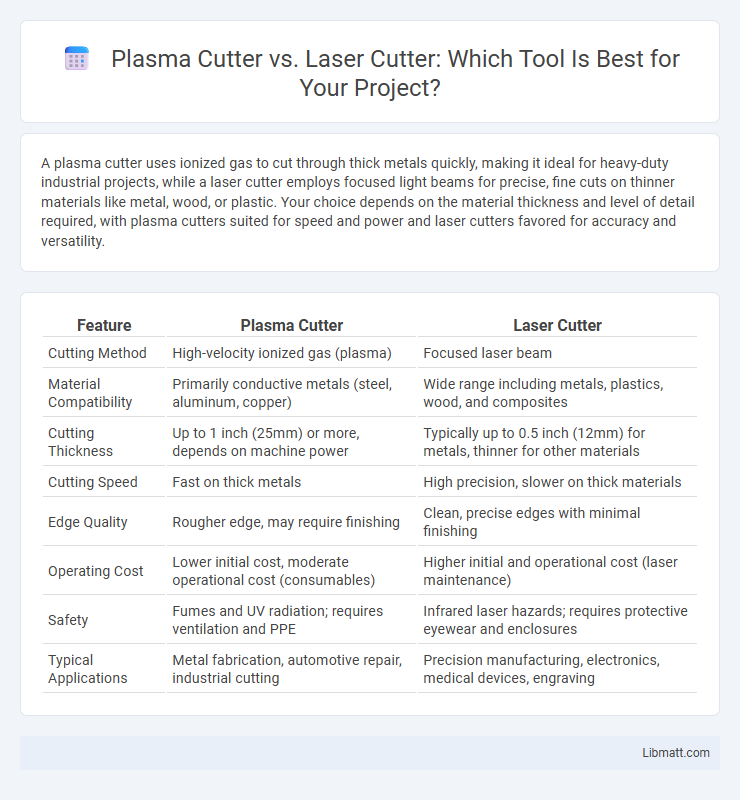

A plasma cutter uses ionized gas to cut through thick metals quickly, making it ideal for heavy-duty industrial projects, while a laser cutter employs focused light beams for precise, fine cuts on thinner materials like metal, wood, or plastic. Your choice depends on the material thickness and level of detail required, with plasma cutters suited for speed and power and laser cutters favored for accuracy and versatility.

Table of Comparison

| Feature | Plasma Cutter | Laser Cutter |

|---|---|---|

| Cutting Method | High-velocity ionized gas (plasma) | Focused laser beam |

| Material Compatibility | Primarily conductive metals (steel, aluminum, copper) | Wide range including metals, plastics, wood, and composites |

| Cutting Thickness | Up to 1 inch (25mm) or more, depends on machine power | Typically up to 0.5 inch (12mm) for metals, thinner for other materials |

| Cutting Speed | Fast on thick metals | High precision, slower on thick materials |

| Edge Quality | Rougher edge, may require finishing | Clean, precise edges with minimal finishing |

| Operating Cost | Lower initial cost, moderate operational cost (consumables) | Higher initial and operational cost (laser maintenance) |

| Safety | Fumes and UV radiation; requires ventilation and PPE | Infrared laser hazards; requires protective eyewear and enclosures |

| Typical Applications | Metal fabrication, automotive repair, industrial cutting | Precision manufacturing, electronics, medical devices, engraving |

Introduction to Plasma Cutters and Laser Cutters

Plasma cutters use a high-velocity jet of ionized gas to melt and blow away metal, making them ideal for quick, rough cuts in thick steel and other conductive metals. Laser cutters employ focused light beams to vaporize material with precision, excelling in detailed, clean cuts on thin metals, plastics, and wood. Both tools serve distinct industrial needs, with plasma cutters favored for heavy-duty fabrication and laser cutters preferred for fine, intricate designs.

How Plasma Cutters Work

Plasma cutters operate by generating a high-velocity jet of ionized gas, or plasma, which is electrically conductive and reaches temperatures up to 30,000degF, allowing it to melt and blow away metal with precision. The cutter uses an inert gas, often compressed air or nitrogen, that is forced through a narrow nozzle and electrically charged by an arc from an electrode, creating the plasma jet. This method excels in cutting thick conductive metals such as steel and aluminum, making plasma cutters ideal for heavy-duty industrial applications compared to laser cutters.

How Laser Cutters Work

Laser cutters use a highly focused beam of coherent light generated by a laser source, which is directed through optics to precisely cut or engrave materials by melting, burning, or vaporizing them. The laser beam's intensity and speed are controlled to achieve clean, intricate cuts with minimal material distortion, suitable for metals, plastics, and wood. This non-contact process allows for high precision and repeatability, making laser cutters ideal for detailed manufacturing and prototyping applications.

Cutting Speed Comparison

Plasma cutters typically offer faster cutting speeds on thicker metals, efficiently slicing through steel up to one inch or more with speeds reaching 20 to 30 inches per minute. Laser cutters excel in precision and speed on thinner materials, often achieving higher cutting speeds on metals under 0.25 inches, sometimes exceeding 40 inches per minute. Your choice depends on material thickness and desired edge quality, with plasma favored for rapid, rough cuts and laser preferred for fine, detailed work.

Material Compatibility

Plasma cutters excel at cutting thick conductive metals like steel, stainless steel, and aluminum, making them ideal for heavy-duty industrial tasks. Laser cutters offer superior precision and can handle a wider range of materials, including non-metals such as wood, plastic, and fabric, with fine detail and minimal waste. Choosing between these tools depends on your material compatibility needs and the nature of your project requirements.

Cut Quality and Precision

Plasma cutters offer robust cutting capabilities for thick metals but often produce rougher edges with a wider kerf, impacting precision. Laser cutters excel in delivering superior cut quality and accuracy, producing clean, narrow cuts with minimal heat distortion ideal for detailed projects. Your choice depends on the required tolerance and finish, with lasers preferred for fine, precise work and plasma suitable for heavier, less detailed metal cutting.

Cost and Investment Analysis

Plasma cutters generally have a lower initial purchase price, making them a cost-effective choice for small to medium-sized workshops focused on cutting thicker metals up to 1 inch. Laser cutters involve a higher upfront investment due to advanced optics and precision technology, but they offer superior cutting accuracy and lower operating costs over time when used for high-volume or fine-detail work. Evaluating total cost of ownership includes considering maintenance expenses, consumables, and energy consumption, where plasma cutters typically incur higher ongoing costs compared to the more energy-efficient laser cutting systems.

Safety Considerations

Plasma cutters generate intense heat and bright arcs, requiring protective gear such as gloves, welding helmets, and flame-resistant clothing to prevent burns and eye damage. Laser cutters, while offering precision, pose risks of laser radiation and toxic fumes, necessitating proper ventilation, safety goggles, and enclosed work areas. You should strictly follow manufacturer guidelines and use appropriate safety equipment to minimize hazards associated with both cutting technologies.

Maintenance and Operational Costs

Plasma cutters generally have lower upfront costs but require frequent consumable replacements and regular torch maintenance, increasing operational expenses over time. Laser cutters demand higher initial investments with costly optics and gas supplies, yet their maintenance intervals are longer and more predictable, often resulting in lower long-term service costs. Carefully evaluating your cutting volume and precision requirements will help determine which technology offers better cost efficiency for your operations.

Choosing the Right Cutter for Your Needs

Choosing the right cutter depends on the material type and thickness you need to work with; plasma cutters excel at cutting thick, conductive metals like steel and aluminum quickly and affordably, while laser cutters offer high precision and cleaner cuts on thinner materials, including metals, plastics, and wood. If Your projects require detailed designs or fine edges, laser cutters provide superior accuracy and minimal heat distortion. For heavy-duty construction or fabrication tasks, plasma cutters deliver faster cutting speeds and lower operational costs, making them ideal for industrial applications.

Plasma cutter vs laser cutter Infographic

libmatt.com

libmatt.com