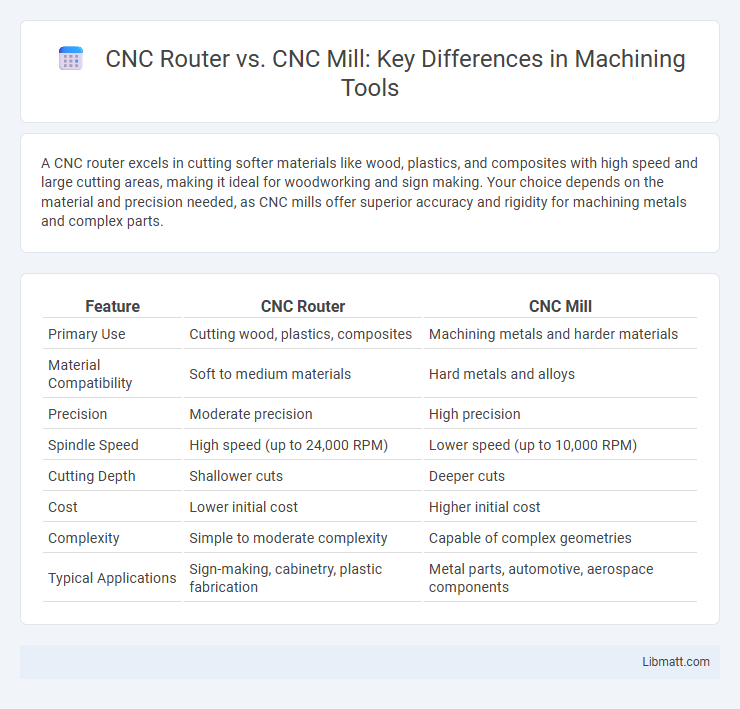

A CNC router excels in cutting softer materials like wood, plastics, and composites with high speed and large cutting areas, making it ideal for woodworking and sign making. Your choice depends on the material and precision needed, as CNC mills offer superior accuracy and rigidity for machining metals and complex parts.

Table of Comparison

| Feature | CNC Router | CNC Mill |

|---|---|---|

| Primary Use | Cutting wood, plastics, composites | Machining metals and harder materials |

| Material Compatibility | Soft to medium materials | Hard metals and alloys |

| Precision | Moderate precision | High precision |

| Spindle Speed | High speed (up to 24,000 RPM) | Lower speed (up to 10,000 RPM) |

| Cutting Depth | Shallower cuts | Deeper cuts |

| Cost | Lower initial cost | Higher initial cost |

| Complexity | Simple to moderate complexity | Capable of complex geometries |

| Typical Applications | Sign-making, cabinetry, plastic fabrication | Metal parts, automotive, aerospace components |

Introduction to CNC Router and CNC Mill

CNC routers and CNC mills are precision machining tools used in manufacturing to cut and shape materials with high accuracy. CNC routers excel at working with softer materials like wood, plastics, and composites, offering faster cutting speeds and larger work areas. CNC mills specialize in metal fabrication, providing superior rigidity and precision for complex three-dimensional parts and fine detailing.

Core Differences Between CNC Routers and CNC Mills

CNC routers primarily excel in cutting softer materials like wood, plastics, and composites, using high-speed spindles for faster, less precise cuts, while CNC mills are designed for harder metals, offering slower speeds with greater precision and rigidity. The core difference lies in their spindle orientation and toolpaths: routers typically have a fixed vertical spindle and large cutting areas ideal for sheets and panels, whereas mills have multi-axis movement enabling detailed 3D machining and complex geometries. Your choice depends on the material type, precision required, and production scale, with routers suited for lightweight, large-scale projects and mills for heavy-duty, intricate parts.

Material Compatibility: CNC Router vs CNC Mill

CNC routers excel in cutting softer materials such as wood, plastics, and composites, offering higher speeds and larger work areas ideal for sheet materials. CNC mills, on the other hand, handle harder metals like aluminum, steel, and titanium with greater precision due to their robust spindle speeds and rigid construction. Material compatibility between CNC routers and CNC mills depends on the type, hardness, and thickness of the workpiece, influencing the choice of machine for optimal performance.

Precision and Tolerances Comparison

CNC routers typically offer precision within +-0.005 inches, making them suitable for cutting softer materials and larger workpieces with moderate accuracy. CNC mills provide higher precision and tighter tolerances, often achieving +-0.0001 inches, ideal for intricate metal parts and detailed machining tasks. Your choice depends on whether extreme accuracy or material flexibility is the priority in your project.

Speed and Efficiency: Router vs Mill

CNC routers typically offer higher speed and greater efficiency for cutting softer materials like wood, plastics, and composites due to their lightweight spindle and faster RPM capabilities. In contrast, CNC mills operate at lower speeds but excel in precision and stability, making them more efficient for machining harder materials such as metals and alloys. The choice between a CNC router and mill depends on the balance between production speed and the complexity or hardness of the material being processed.

Typical Applications of CNC Routers and Mills

CNC routers excel in woodworking, sign making, and plastics cutting, offering high-speed and large-area material processing. CNC mills are preferred for metalworking, precision machining, and complex part fabrication, providing superior accuracy and rigidity. Both machines serve distinct roles depending on material type, required precision, and application scale.

Cost Considerations and Budget Planning

CNC routers generally cost less than CNC mills, making them more budget-friendly for woodworking and softer material projects. CNC mills, designed for precision with metals and harder materials, typically involve higher initial investment and maintenance expenses. Assessing your material needs and production volume ensures your budget prioritizes the most cost-effective solution for your manufacturing goals.

Workspace and Size Requirements

CNC routers typically offer larger workspace areas, making them ideal for handling bigger materials such as wood, plastics, and softer metals. CNC mills have more compact working envelopes, suitable for precision machining of smaller, denser materials like steel and aluminum. Your choice depends on the size of your projects and the available space for the machine in your workshop.

Maintenance and Longevity Factors

CNC routers require regular maintenance of spindle bearings and dust extraction systems to prevent overheating and debris buildup, ensuring prolonged tool life. CNC mills demand careful lubrication of ball screws and precise alignment checks to maintain accuracy and reduce wear on mechanical components. Understanding these maintenance nuances helps you maximize the longevity and performance of your CNC machinery.

Which to Choose: CNC Router or CNC Mill?

Choosing between a CNC router and a CNC mill depends on the materials and precision required for your project. CNC routers excel in cutting softer materials like wood, plastics, and composites with high speed and large work areas, while CNC mills are better suited for harder materials such as metals, providing superior accuracy and intricate detailing. Assess your production needs and material specifications to determine which machine aligns best with your manufacturing goals.

CNC router vs CNC mill Infographic

libmatt.com

libmatt.com