Helical gear cutters produce gears with angled teeth that offer smoother and quieter operation, making them ideal for high-speed applications. Spur gear cutters create gears with straight teeth, suitable for simple, low-speed machinery where cost-effectiveness and ease of manufacturing are priorities.

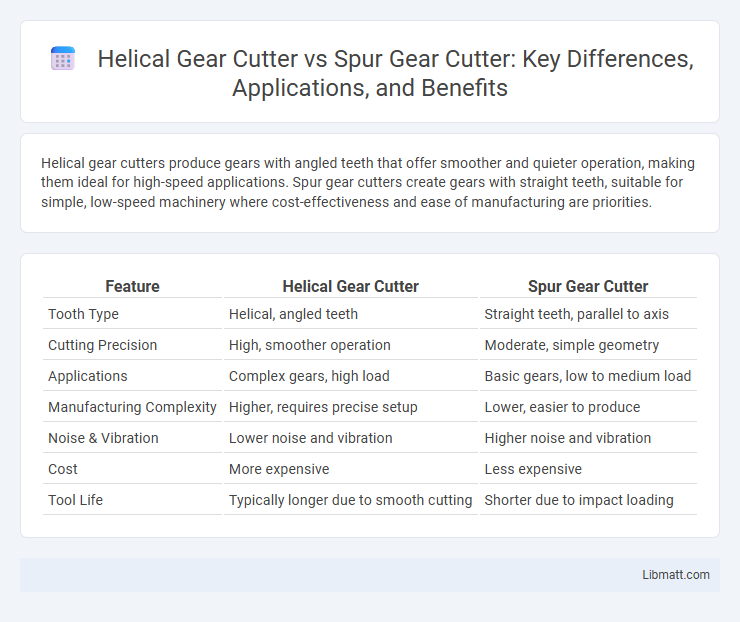

Table of Comparison

| Feature | Helical Gear Cutter | Spur Gear Cutter |

|---|---|---|

| Tooth Type | Helical, angled teeth | Straight teeth, parallel to axis |

| Cutting Precision | High, smoother operation | Moderate, simple geometry |

| Applications | Complex gears, high load | Basic gears, low to medium load |

| Manufacturing Complexity | Higher, requires precise setup | Lower, easier to produce |

| Noise & Vibration | Lower noise and vibration | Higher noise and vibration |

| Cost | More expensive | Less expensive |

| Tool Life | Typically longer due to smooth cutting | Shorter due to impact loading |

Introduction to Gear Cutting Technologies

Helical gear cutters create angled teeth that provide smoother and quieter operation by gradually engaging gears, while spur gear cutters produce straight teeth suited for simpler, lower-speed applications. Gear cutting technologies involve precise machining processes such as hobbing, shaping, or milling, affecting gear performance and durability. Choosing the right cutter impacts your gear's efficiency, noise level, and suitability for specific mechanical systems.

Overview of Spur Gear Cutters

Spur gear cutters are precision tools designed specifically for cutting straight-toothed gears used in various mechanical applications such as automotive transmissions and machinery. They feature multiple teeth arranged parallel to the axis of rotation, enabling efficient and accurate removal of material to create precise gear profiles. Commonly made from high-speed steel or carbide, spur gear cutters ensure durability and sharpness for consistent performance in generating standard involute gear teeth.

Fundamentals of Helical Gear Cutters

Helical gear cutters feature angled teeth that allow for smoother and quieter gear meshing compared to spur gear cutters, which have straight teeth. These cutters are designed to produce gears with a helix angle, improving load distribution and reducing noise in gearboxes. Your machining process benefits from precise control over helix angles, enhancing gear performance in complex mechanical systems.

Key Differences Between Helical and Spur Gear Cutters

Helical gear cutters feature angled teeth designed to cut gears with a spiral tooth profile, providing smoother operation and quieter performance compared to spur gear cutters, which have straight teeth for simpler manufacturing but more noise and vibration. Spur gear cutters are typically easier to produce and more cost-effective, whereas helical gear cutters require precise alignment and specialized tooling to achieve the desired helix angle. The choice between helical and spur gear cutters impacts gear efficiency, load distribution, and application suitability, with helical gears preferred for high-speed, high-load environments and spur gears suited for low-speed, low-load tasks.

Gear Cutting Efficiency and Precision

Helical gear cutters offer superior gear cutting efficiency and precision due to their angled teeth, which ensure smoother engagement and reduced noise compared to spur gear cutters with straight teeth. The continuous contact during machining minimizes vibrations and enhances the accuracy of tooth profiles, resulting in high-quality gears suitable for demanding applications. Your selection of a helical gear cutter can significantly improve production speed and precision, especially in high-performance gear manufacturing.

Application Areas: Helical vs Spur Gear Cutters

Helical gear cutters are ideal for applications requiring smooth and quiet operation, such as automotive transmissions, gearboxes, and precision machinery, where angled teeth reduce noise and vibration. Spur gear cutters are best suited for simpler, lighter-load applications like household appliances, clocks, and basic machinery, offering ease of manufacturing and cost-effectiveness with straight teeth. Choosing the right cutter depends on your gear design needs, load requirements, and desired performance characteristics.

Noise and Vibration Considerations

Helical gear cutters produce gears with angled teeth that engage gradually, resulting in smoother operation and significantly reduced noise and vibration compared to spur gear cutters, which create straight-toothed gears with sudden engagement causing higher noise levels. Your choice of a helical gear cutter can enhance mechanical efficiency and prolong machine life by minimizing vibration-induced wear. Noise-sensitive applications benefit from helical gears due to their quieter performance and superior load distribution.

Manufacturing Challenges and Solutions

Helical gear cutters face complex manufacturing challenges due to their angled teeth, requiring precise indexing and intricate grinding processes to maintain accuracy and surface finish. Spur gear cutters offer simpler manufacturing with straight teeth, allowing easier tooling and shorter production times but may cause higher noise and stress levels in operation. Advanced CNC machining and coating technologies help overcome the difficulties of helical gear cutter manufacturing by enhancing tool life and cutting precision.

Cost Analysis: Helical vs Spur Gear Cutting

Helical gear cutters generally cost more than spur gear cutters due to their complex geometry and manufacturing process, requiring precision grinding and higher material quality. Spur gear cutters are more economical, making them suitable for high-volume production where cost efficiency is critical. Your choice should balance initial tooling investment against application requirements, considering helix angle benefits and noise reduction against budget constraints.

Choosing the Right Gear Cutter for Your Needs

Selecting the right gear cutter involves understanding the specific requirements of your project, such as gear type, precision, and application. Helical gear cutters provide smoother operation and better load distribution ideal for high-speed, high-load environments, whereas spur gear cutters are simpler and cost-effective for lower-speed applications. Your choice should align with desired gear performance and manufacturing capabilities to ensure optimal results.

Helical gear vs spur gear cutter Infographic

libmatt.com

libmatt.com