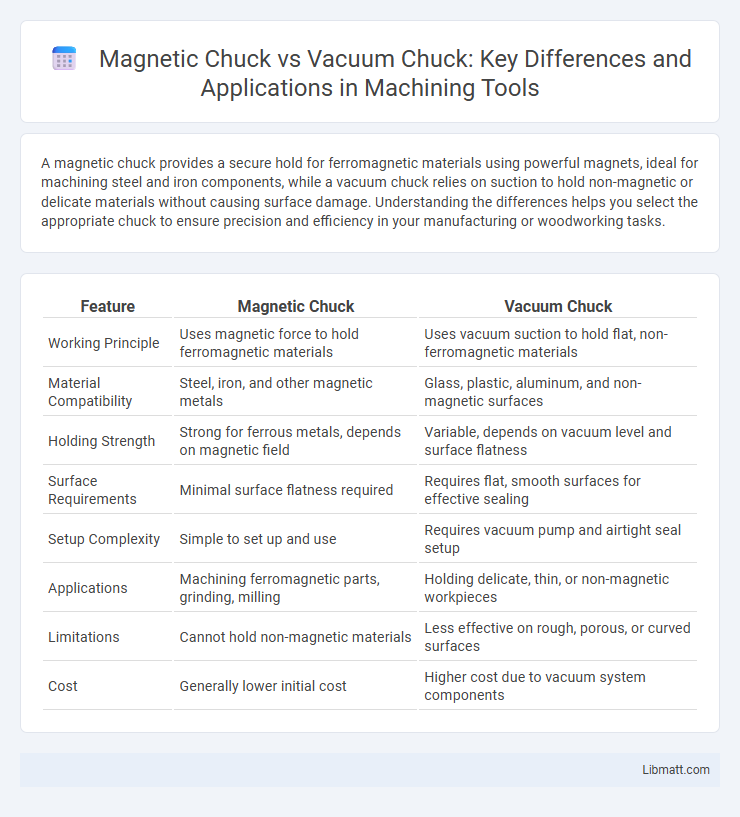

A magnetic chuck provides a secure hold for ferromagnetic materials using powerful magnets, ideal for machining steel and iron components, while a vacuum chuck relies on suction to hold non-magnetic or delicate materials without causing surface damage. Understanding the differences helps you select the appropriate chuck to ensure precision and efficiency in your manufacturing or woodworking tasks.

Table of Comparison

| Feature | Magnetic Chuck | Vacuum Chuck |

|---|---|---|

| Working Principle | Uses magnetic force to hold ferromagnetic materials | Uses vacuum suction to hold flat, non-ferromagnetic materials |

| Material Compatibility | Steel, iron, and other magnetic metals | Glass, plastic, aluminum, and non-magnetic surfaces |

| Holding Strength | Strong for ferrous metals, depends on magnetic field | Variable, depends on vacuum level and surface flatness |

| Surface Requirements | Minimal surface flatness required | Requires flat, smooth surfaces for effective sealing |

| Setup Complexity | Simple to set up and use | Requires vacuum pump and airtight seal setup |

| Applications | Machining ferromagnetic parts, grinding, milling | Holding delicate, thin, or non-magnetic workpieces |

| Limitations | Cannot hold non-magnetic materials | Less effective on rough, porous, or curved surfaces |

| Cost | Generally lower initial cost | Higher cost due to vacuum system components |

Introduction to Workholding: Magnetic vs Vacuum Chucks

Magnetic chucks provide powerful holding force using magnetic fields, ideal for ferrous metal machining due to their strong grip and quick setup. Vacuum chucks rely on suction to secure non-ferrous or delicate workpieces, offering uniform pressure without surface damage. Choosing between magnetic and vacuum chucks depends on material type, surface finish requirements, and the precision needed for machining tasks.

How Magnetic Chucks Work

Magnetic chucks operate by generating a powerful magnetic field through embedded permanent magnets or electromagnets, which securely clamp ferromagnetic workpieces onto the chuck surface without physical deformation. These chucks provide precise holding force ideal for grinding and machining operations, ensuring minimal slippage and consistent positioning. Magnetic flux concentration design optimizes holding strength while allowing quick workpiece changes, enhancing efficiency in metalworking applications.

How Vacuum Chucks Operate

Vacuum chucks operate by creating a pressure differential between the workpiece and the chuck surface, using a vacuum pump to remove air and generate suction that holds the object securely in place. This method is ideal for non-magnetic materials and delicate components, providing uniform holding force without surface damage. The vacuum pressure can be precisely controlled to ensure stability during machining or inspection processes, making it versatile for various industrial applications.

Material Compatibility: Magnetic vs Vacuum Chucks

Magnetic chucks are ideal for ferromagnetic materials such as steel and iron, providing strong holding force for machining operations. Vacuum chucks offer broad compatibility, effectively securing non-ferrous metals, plastics, glass, and composites by creating suction without magnetic interference. Choosing between magnetic and vacuum chucks depends primarily on the workpiece material and the need for secure, non-deforming clamping.

Advantages of Magnetic Chucks

Magnetic chucks offer superior holding power for ferromagnetic materials, enabling precision machining without slippage. They provide quick setup and release, enhancing workflow efficiency in metalworking environments. Unlike vacuum chucks, magnetic systems maintain consistent force regardless of surface porosity or irregularities.

Benefits of Vacuum Chucks

Vacuum chucks provide superior holding power for delicate or non-ferrous materials without causing surface damage, making them ideal for woodworking, glass, and composites. They offer quick setup and release times, improving efficiency in high-volume production environments. Additionally, vacuum chucks accommodate irregularly shaped objects and provide uniform pressure distribution, enhancing stability during precision machining.

Limitations and Challenges of Magnetic Chucks

Magnetic chucks face limitations such as reduced holding power on non-ferrous or thin workpieces, restricting their versatility. They can generate residual magnetism, which may interfere with sensitive electronic components or cause difficulties in workpiece removal. Additionally, magnetic chucks often require significant power consumption and regular maintenance to prevent demagnetization or mechanical wear.

Limitations and Challenges of Vacuum Chucks

Vacuum chucks face limitations in holding porous or irregularly shaped materials due to insufficient seal formation, which compromises gripping strength and precision. They also require smooth, non-porous surfaces and may struggle with maintaining vacuum levels during extended operations or in environments with air leaks. Your choice between magnetic and vacuum chucks should consider these challenges, especially for applications involving non-metallic or delicate workpieces where vacuum chuck performance might be unreliable.

Choosing the Right Chuck for Your Application

Magnetic chucks excel in holding ferrous metal workpieces with strong, uniform magnetic force, making them ideal for grinding, milling, and turning operations involving steel or iron. Vacuum chucks provide a versatile, non-marring gripping solution suitable for delicate, non-ferrous, or thin materials such as glass, ceramics, and composites, especially in precision machining or inspection tasks. Selecting the right chuck depends on material type, workpiece shape, machining process, and required holding strength to ensure optimal performance and surface finish.

Conclusion: Magnetic Chuck vs Vacuum Chuck Comparison

Magnetic chucks provide strong holding power for ferromagnetic materials, making them ideal for heavy-duty machining and grinding tasks, while vacuum chucks excel in securing delicate, non-magnetic, or irregularly shaped workpieces without surface damage. Your choice depends on material type, workpiece geometry, and precision requirements, with magnetic chucks offering robustness and vacuum chucks delivering versatility. In summary, magnetic chucks are best for metal components requiring high stability, whereas vacuum chucks suit softer materials needing gentle yet reliable holding.

Magnetic chuck vs vacuum chuck Infographic

libmatt.com

libmatt.com