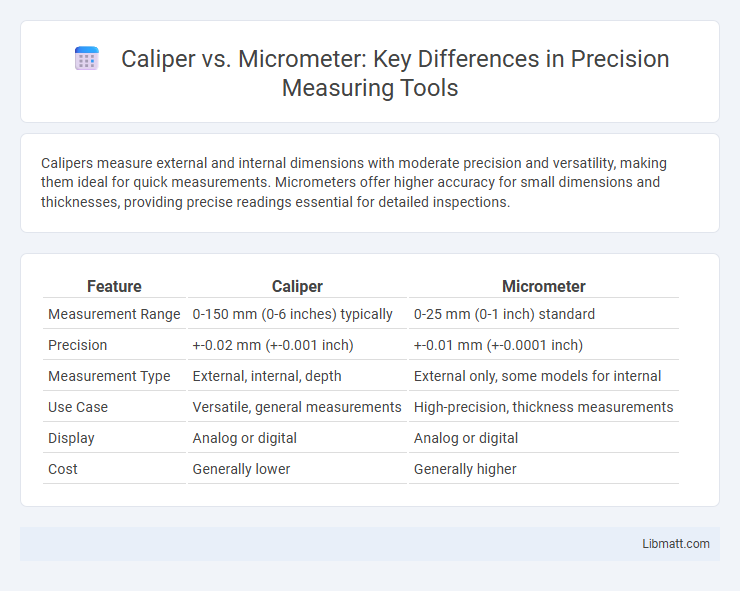

Calipers measure external and internal dimensions with moderate precision and versatility, making them ideal for quick measurements. Micrometers offer higher accuracy for small dimensions and thicknesses, providing precise readings essential for detailed inspections.

Table of Comparison

| Feature | Caliper | Micrometer |

|---|---|---|

| Measurement Range | 0-150 mm (0-6 inches) typically | 0-25 mm (0-1 inch) standard |

| Precision | +-0.02 mm (+-0.001 inch) | +-0.01 mm (+-0.0001 inch) |

| Measurement Type | External, internal, depth | External only, some models for internal |

| Use Case | Versatile, general measurements | High-precision, thickness measurements |

| Display | Analog or digital | Analog or digital |

| Cost | Generally lower | Generally higher |

Introduction: Caliper vs Micrometer

Calipers and micrometers are precision measuring tools used for different levels of accuracy in dimensional measurements. Calipers offer versatility with their ability to measure internal, external, and depth dimensions, typically providing resolution up to 0.01 mm. Micrometers deliver higher precision with measurements accurate to 0.001 mm or better, ideal for small objects requiring exact thickness or diameter readings.

Understanding Calipers: Types and Uses

Calipers are precision measuring tools available in various types such as vernier, dial, and digital, each designed for specific measurement tasks including external, internal, and depth measurements. They provide quick and versatile dimensional readings with an accuracy typically ranging from 0.01 mm to 0.02 mm, making them ideal for engineering, machining, and quality control applications. Used extensively in metalworking and manufacturing, calipers enable precise measurement of parts and components with ease and repeatability.

Overview of Micrometers: Types and Applications

Micrometers, precision instruments for measuring small dimensions, come in various types including outside, inside, depth, and screw gauge micrometers, each designed for specific tasks such as measuring thickness, internal diameters, or depth of grooves. Applications of micrometers span mechanical engineering, machining, and quality control, where accuracy up to 0.001 mm is essential. Their versatility and high precision make them indispensable for detailed inspections and manufacturing processes requiring exact measurements.

Key Differences Between Calipers and Micrometers

Calipers provide versatile measurement options, including inside, outside, and depth dimensions, with typical accuracy ranging from 0.01 mm to 0.02 mm, making them suitable for general measurements. Micrometers offer higher precision, often up to 0.001 mm, but measure only specific dimensions like thickness or diameter, ideal for applications requiring exactness. The structural design of micrometers restricts their use to external or internal measurements on smaller objects, while calipers accommodate a broader range of measurement tasks due to their adjustable jaws and features.

Accuracy and Precision Comparison

Calipers typically offer measurement accuracy ranging from +-0.02 mm to +-0.05 mm, making them suitable for general-purpose tasks, whereas micrometers provide superior precision with accuracy often around +-0.001 mm. The precision of micrometers is due to their finely threaded spindle, allowing for highly repeatable and consistent measurements of very small dimensions. In applications demanding exact tolerance and detailed dimensional control, micrometers are preferred over calipers for their enhanced measurement reliability.

Measurement Range and Versatility

Calipers typically offer a measurement range up to 6 inches (150 mm) and can measure both internal and external dimensions, as well as depths, making them highly versatile for various applications. Micrometers usually provide a more limited range, often up to 1 inch (25 mm), but deliver greater precision for specific measurements such as thickness or diameter. The broader measurement capability of calipers contrasts with the micrometer's specialized accuracy in narrow ranges.

Ease of Use and User Experience

Calipers offer greater ease of use with their versatile measuring capabilities and straightforward digital or dial readouts, making them ideal for quick, multi-dimensional measurements. Micrometers, while providing higher precision, require more careful handling and calibration, which can slow down the measuring process for inexperienced users. Your choice depends on whether convenience or accuracy takes precedence in your specific measuring tasks.

Cost and Maintenance Considerations

Calipers are generally more affordable and require less maintenance compared to micrometers, making them a cost-effective choice for routine measurements in various applications. Micrometers, while pricier, provide higher precision and durability, often necessitating regular calibration and careful handling to maintain accuracy. Your decision should balance budget constraints with the need for precision and ongoing upkeep.

Choosing the Right Tool for Your Needs

Selecting between a caliper and a micrometer depends on the precision required and the type of measurement. Calipers offer versatile measurements for internal, external, and depth dimensions with typical accuracy up to 0.02 mm, suitable for general engineering tasks. Micrometers provide higher accuracy, often within 0.001 mm, ideal for highly precise measurements of small components in mechanical and manufacturing applications.

Conclusion: Caliper or Micrometer?

Choosing between a caliper and a micrometer depends on the precision and measurement range you require for your project. Calipers offer versatility with the ability to measure inside, outside, and depth dimensions, making them suitable for general use. Micrometers provide higher accuracy for specific measurements, especially when exact thickness or diameter readings are essential.

Caliper vs micrometer Infographic

libmatt.com

libmatt.com