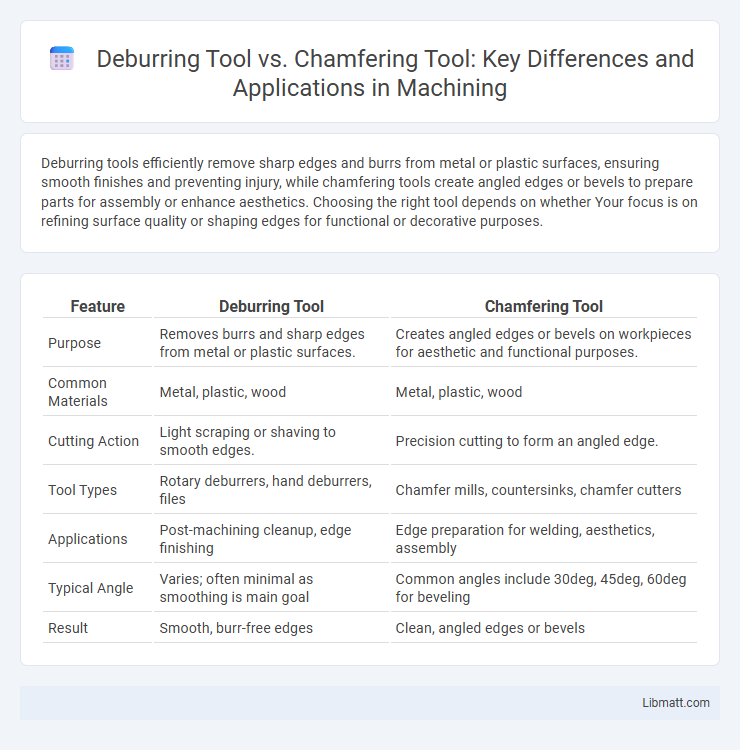

Deburring tools efficiently remove sharp edges and burrs from metal or plastic surfaces, ensuring smooth finishes and preventing injury, while chamfering tools create angled edges or bevels to prepare parts for assembly or enhance aesthetics. Choosing the right tool depends on whether Your focus is on refining surface quality or shaping edges for functional or decorative purposes.

Table of Comparison

| Feature | Deburring Tool | Chamfering Tool |

|---|---|---|

| Purpose | Removes burrs and sharp edges from metal or plastic surfaces. | Creates angled edges or bevels on workpieces for aesthetic and functional purposes. |

| Common Materials | Metal, plastic, wood | Metal, plastic, wood |

| Cutting Action | Light scraping or shaving to smooth edges. | Precision cutting to form an angled edge. |

| Tool Types | Rotary deburrers, hand deburrers, files | Chamfer mills, countersinks, chamfer cutters |

| Applications | Post-machining cleanup, edge finishing | Edge preparation for welding, aesthetics, assembly |

| Typical Angle | Varies; often minimal as smoothing is main goal | Common angles include 30deg, 45deg, 60deg for beveling |

| Result | Smooth, burr-free edges | Clean, angled edges or bevels |

Introduction to Deburring and Chamfering Tools

Deburring tools remove sharp edges and burrs left after machining, ensuring smooth and safe surfaces on metal, plastic, or wood parts. Chamfering tools create angled edges or bevels, improving aesthetics and part fit for assembly or welding. Your choice between these tools depends on the specific finishing requirement, whether it's edge cleanup or precise edge shaping.

Understanding Deburring Tools

Deburring tools are specifically designed to remove sharp edges and burrs from metal, plastic, or wood surfaces, enhancing safety and ensuring smooth finishes. These tools typically feature replaceable blades or edges that adapt to various materials and shapes, delivering precise control during finishing processes. Understanding the function and application of your deburring tool helps improve product quality by preventing injuries and ensuring that parts fit together seamlessly.

Overview of Chamfering Tools

Chamfering tools are designed to create angled edges or bevels on workpieces, improving aesthetics and removing sharp corners for safety. Unlike deburring tools, which primarily smooth rough edges and remove burrs, chamfering tools precisely shape edges to specified angles, often used in metalworking and woodworking industries. Your choice of chamfering tool depends on material type, angle precision, and the desired finish quality.

Key Differences Between Deburring and Chamfering Tools

Deburring tools are designed to remove burrs and sharp edges from metal or plastic workpieces, ensuring a smooth finish and safe handling, whereas chamfering tools create a beveled edge or angled surface, typically to prepare parts for assembly or improve aesthetics. Deburring focuses on edge cleanup and defect removal without significantly altering the part geometry, while chamfering shapes or modifies edges to specific angles like 45 degrees for functional or design purposes. Key differences include their primary functions--deburring for defect removal and chamfering for edge shaping--and the impact on part dimensions, as chamfering alters the edge size while deburring maintains original dimensions.

Common Applications for Deburring Tools

Deburring tools are commonly used to remove sharp edges, burrs, and imperfections from metal, plastic, and wood surfaces after cutting or machining processes. These tools ensure smooth finishes in manufacturing, automotive, aerospace, and metal fabrication industries, enhancing product safety and functionality. Your workpieces benefit from improved precision and reduced risk of injury or equipment damage by using deburring tools in post-production cleanup.

Typical Uses for Chamfering Tools

Chamfering tools are primarily used to create angled edges on metal, plastic, or wood surfaces, improving part fit and assembly. They are ideal for preparing edges for welding, removing sharp corners, and enhancing aesthetic appeal in manufacturing processes. Common applications include beveling edges on machined components, deburring hole entrances, and creating lead-ins for mating parts.

Material Compatibility: Deburring vs Chamfering

Deburring tools excel in removing burrs from softer materials like aluminum, plastic, and mild steel, ensuring smooth edges without altering the material's dimensions significantly. Chamfering tools are designed for harder materials such as stainless steel and cast iron, precisely machining angled edges or bevels to improve fit and assembly. Your choice between deburring and chamfering tools depends on the material compatibility and the desired finish quality.

Advantages and Limitations of Deburring Tools

Deburring tools offer precise edge finishing by removing burrs and sharp edges, enhancing the safety and appearance of metal or plastic components. These tools excel in providing smooth, clean surfaces but may have limitations when handling larger chamfers or intricate angled cuts that require specialized chamfering tools. Your choice of a deburring tool should balance efficiency in burr removal with the complexity of the task to achieve optimal results.

Pros and Cons of Chamfering Tools

Chamfering tools offer precise edge finishing, enhancing both aesthetics and functionality by removing sharp edges and preparing surfaces for welding or assembly. Their main advantages include improved safety, better fit between parts, and reduced risk of material fatigue; however, chamfering tools can be less effective on irregular or excessively rough surfaces and may require specialized equipment or skill for optimal results. You should consider the trade-offs between efficiency and surface precision when choosing between chamfering and deburring tools.

Choosing the Right Tool for Your Project

Selecting the right tool for your project depends on the specific edge finish you need--deburring tools excel at removing rough edges and burrs for a smooth surface, while chamfering tools create angled edges by cutting bevels. Deburring tools are ideal for improving safety and assembly fit, whereas chamfering tools enhance aesthetic appeal and function by preparing edges for welding or fastening. Understanding your project requirements will help you determine whether edge smoothing or angled finishing is the priority.

Deburring tool vs chamfering tool Infographic

libmatt.com

libmatt.com