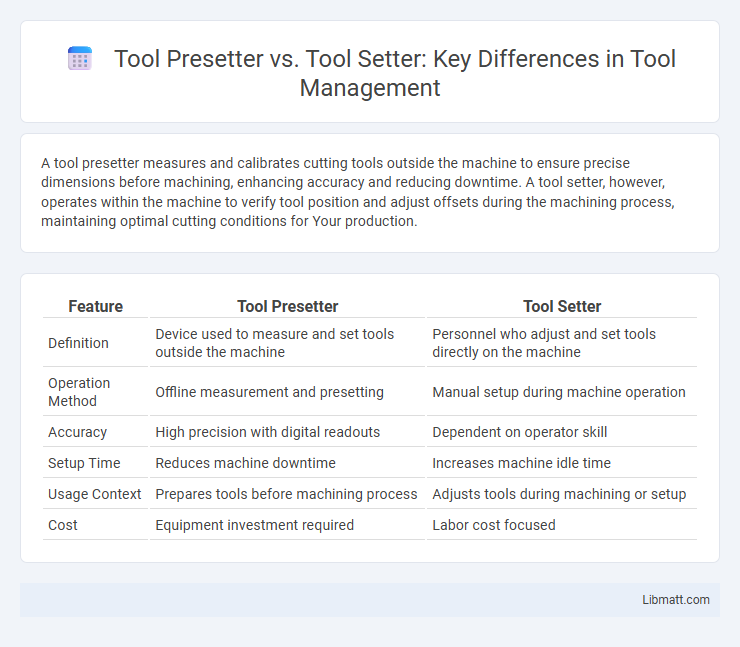

A tool presetter measures and calibrates cutting tools outside the machine to ensure precise dimensions before machining, enhancing accuracy and reducing downtime. A tool setter, however, operates within the machine to verify tool position and adjust offsets during the machining process, maintaining optimal cutting conditions for Your production.

Table of Comparison

| Feature | Tool Presetter | Tool Setter |

|---|---|---|

| Definition | Device used to measure and set tools outside the machine | Personnel who adjust and set tools directly on the machine |

| Operation Method | Offline measurement and presetting | Manual setup during machine operation |

| Accuracy | High precision with digital readouts | Dependent on operator skill |

| Setup Time | Reduces machine downtime | Increases machine idle time |

| Usage Context | Prepares tools before machining process | Adjusts tools during machining or setup |

| Cost | Equipment investment required | Labor cost focused |

Introduction to Tool Presetter and Tool Setter

A tool presetter is a precision measurement device used to set and measure cutting tools outside the CNC machine, ensuring accurate tool dimensions before machining. A tool setter, on the other hand, is an operator who manually adjusts and verifies tool length and diameter directly on the machine to maintain machining accuracy. Both play crucial roles in optimizing machining efficiency and reducing downtime by ensuring tools are correctly prepared and verified.

Key Differences Between Tool Presetter and Tool Setter

Tool presetters measure and set cutting tools outside the machine, ensuring precise tool length and diameter before machining begins, which maximizes machine uptime and accuracy. Tool setters operate inside the machine, adjusting and verifying tool positions during the machining process to maintain consistent part quality. Understanding these differences helps you optimize tool management and improve production efficiency in your manufacturing workflow.

Importance of Tool Measurement in CNC Machining

Tool presetters play a crucial role in CNC machining by accurately measuring cutting tools before they are loaded into the machine, ensuring precise tool length and diameter data to minimize setup time and reduce material waste. Unlike tool setters, who measure tools directly on the CNC machine, tool presetters operate offline, increasing machine uptime and enhancing production efficiency through consistent tool measurement. Precise tool measurement is essential for maintaining tight tolerances, improving surface finish quality, and preventing costly machining errors.

How Tool Presetters Work: Process and Benefits

Tool presetters precisely measure and set cutting tools before they are mounted on CNC machines, using advanced sensors and laser technology to ensure exact dimensions and angles. This process reduces machine downtime by allowing operators to load pre-measured tools, enhancing overall productivity and consistency in machining operations. Implementing tool presetters improves tool life management, optimizes tool changeover times, and maintains high machining accuracy across production cycles.

How Tool Setters Operate: In-Machine Measurement

Tool setters operate by performing in-machine measurement processes that precisely verify tool dimensions and offsets directly on the CNC machine. They utilize specialized probes and sensors to capture accurate data on tool length, diameter, and wear, ensuring optimal machining accuracy and reducing setup time. This real-time measurement capability enhances production efficiency by minimizing errors and enabling immediate adjustments without removing the tool from the machine.

Accuracy Comparison: Tool Presetter vs Tool Setter

Tool presetters provide highly accurate measurement and setup of cutting tools outside the machine, reducing setup time and improving repeatability by minimizing errors caused during manual measurement. Tool setters, positioned inside CNC machines, rely on in-process tool calibration but may experience variability due to machine conditions and operator influence, resulting in slightly lower precision. Overall, tool presetters offer superior accuracy for tool length and diameter measurements, enhancing machining consistency and efficiency.

Efficiency and Productivity: Which Tool is Superior?

Tool presetters enhance efficiency by allowing precise measurement and setting of cutting tools offline, reducing machine downtime and ensuring consistent tool accuracy. Tool setters, while essential for verifying tool dimensions directly on the machine, often increase setup time and interrupt production flow. The integration of a tool presetter typically results in higher productivity due to streamlined preparation and minimized errors before machining begins.

Cost Considerations: Investment and ROI Analysis

Tool presetters require a higher initial investment due to advanced technology and automation features compared to traditional tool setters. However, tool presetters offer significant ROI by reducing machine downtime, improving accuracy, and enabling faster tool changes. The cost-benefit analysis shows that long-term savings and productivity gains often outweigh the upfront expense, making tool presetters a strategic investment for high-volume or precision machining environments.

Application Scenarios for Tool Presetters and Tool Setters

Tool presetters are primarily used in manufacturing environments to measure and preset tool dimensions offline, enabling faster machine setups and minimizing downtime during production runs. Tool setters operate directly on the machine tool, verifying and adjusting tools during machining to ensure precision and compensate for tool wear in real-time. Your choice between a tool presetter and a tool setter depends on whether offline preparation or in-process tool management best suits your application's efficiency and accuracy requirements.

Choosing the Right Tool Measurement Solution for Your Shop

Tool presetters provide precise, offline measurement of cutting tools, allowing Your shop to reduce machine downtime by setting tools before production starts. Tool setters measure tool length and diameter directly on the machine, ensuring real-time accuracy and immediate adjustments during machining. Selecting between a tool presetter and tool setter depends on your shop's workflow priorities, machining volume, and accuracy requirements for efficient tool measurement and setup.

Tool presetter vs tool setter Infographic

libmatt.com

libmatt.com