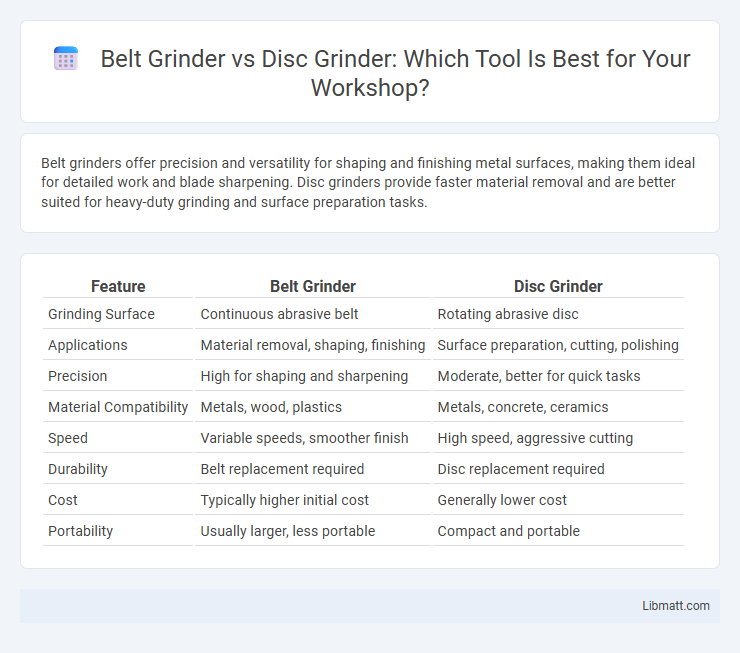

Belt grinders offer precision and versatility for shaping and finishing metal surfaces, making them ideal for detailed work and blade sharpening. Disc grinders provide faster material removal and are better suited for heavy-duty grinding and surface preparation tasks.

Table of Comparison

| Feature | Belt Grinder | Disc Grinder |

|---|---|---|

| Grinding Surface | Continuous abrasive belt | Rotating abrasive disc |

| Applications | Material removal, shaping, finishing | Surface preparation, cutting, polishing |

| Precision | High for shaping and sharpening | Moderate, better for quick tasks |

| Material Compatibility | Metals, wood, plastics | Metals, concrete, ceramics |

| Speed | Variable speeds, smoother finish | High speed, aggressive cutting |

| Durability | Belt replacement required | Disc replacement required |

| Cost | Typically higher initial cost | Generally lower cost |

| Portability | Usually larger, less portable | Compact and portable |

Introduction to Belt Grinders and Disc Grinders

Belt grinders use a continuous loop of abrasive belt for fast, efficient material removal and shaping, ideal for metalworking and woodworking tasks requiring precision. Disc grinders feature a flat, circular abrasive disc that excels in surface finishing, grinding, and smoothing applications on metal and other materials. Choosing between the two depends on your specific project requirements, as belt grinders offer versatility in contouring while disc grinders provide consistent surface abrasion.

Core Differences Between Belt Grinders and Disc Grinders

Belt grinders use an abrasive belt to provide a continuous grinding surface, ideal for shaping and smoothing large or irregular surfaces, while disc grinders utilize a rotating abrasive disc suited for precision grinding and finishing tasks. Belt grinders offer greater versatility in material removal and surface contouring due to their elongated belt design, whereas disc grinders provide faster stock removal on smaller, flat areas. Understanding these core differences helps you select the right tool based on your specific grinding requirements and project goals.

Applications: When to Use Belt Grinders

Belt grinders excel in applications requiring precise metal removal, surface finishing, and shaping of complex contours, making them ideal for metal fabrication, knife making, and welding projects. You should use a belt grinder when working on tasks that demand consistent pressure and a smooth, even finish across larger surfaces. Their ability to handle heavy-duty grinding and versatile abrasive options sets them apart from disc grinders, which are better suited for quick material removal and edge grinding.

Applications: When to Use Disc Grinders

Disc grinders excel in precision tasks such as grinding welds, removing rust, and shaping metal edges, making them ideal for detailed surface finishing and spot work. You should choose a disc grinder when working on smaller surfaces or requiring intricate grinding with better control and less material removal. Their versatility in handling metal and masonry surfaces suits applications needing sharp, tight grinding or polishing.

Material Removal Rate: Belt vs Disc

Belt grinders offer a higher material removal rate compared to disc grinders due to their continuous belt surface, which allows for more effective abrasion over larger areas. Disc grinders are better suited for precision work and detailed grinding but typically remove material at a slower rate because of the limited contact surface of the rotating disc. Choosing a belt grinder can significantly improve Your efficiency when needing to remove large amounts of material quickly.

Precision and Finish Quality Comparison

Belt grinders offer superior precision and a smoother finish due to their continuous, consistent surface contact, making them ideal for detailed work and fine shaping. Disc grinders provide faster material removal but often leave a rougher surface, requiring additional finishing steps to achieve a polished look. Choosing a belt grinder enhances your ability to achieve high-quality, precise finishes on metals and other materials.

Versatility and Adaptability in Workshop Settings

Belt grinders offer superior versatility with adjustable belt speeds and various grit options, making them ideal for shaping, sharpening, and finishing different materials in workshop settings. Disc grinders excel in adaptability for surface grinding and edge shaping, especially on smaller workpieces, due to their compact design and interchangeable discs. Combining both tools in a workshop enhances efficiency by covering a broader range of metalworking and woodworking tasks with precision.

Maintenance and Longevity Considerations

Belt grinders require regular belt replacement and frequent tracking adjustments to maintain optimal performance, with abrasive belts wearing out faster under heavy use. Disc grinders typically have longer-lasting grinding discs but demand consistent disc changes and careful cleaning to prevent buildup and overheating. Proper maintenance of bearings and dust extraction systems significantly extends the lifespan of both machines, with belt grinders often needing more frequent attention due to their moving parts and belt tension mechanisms.

Cost and Investment Analysis

Belt grinders generally require a higher initial investment due to their larger size and more complex components, but they offer greater versatility and productivity for heavy-duty metalworking tasks. Disc grinders tend to have a lower upfront cost, making them more accessible for smaller workshops or occasional use, though they may incur higher long-term expenses from frequent disc replacements. Evaluating operating costs, maintenance, and application needs is essential for an effective cost and investment analysis between belt grinders and disc grinders.

Which Grinder is Right for Your Needs?

Choosing between a belt grinder and a disc grinder depends on the specific tasks and materials you work with. Belt grinders excel at heavy stock removal and shaping, providing continuous abrasive surfaces ideal for metal fabrication and knife making, while disc grinders offer precision and versatility for surface finishing, grinding, and blending on flat or curved surfaces. Assess your project requirements and workspace to determine which grinder aligns with your skill set and delivers optimal performance for your needs.

Belt grinder vs disc grinder Infographic

libmatt.com

libmatt.com