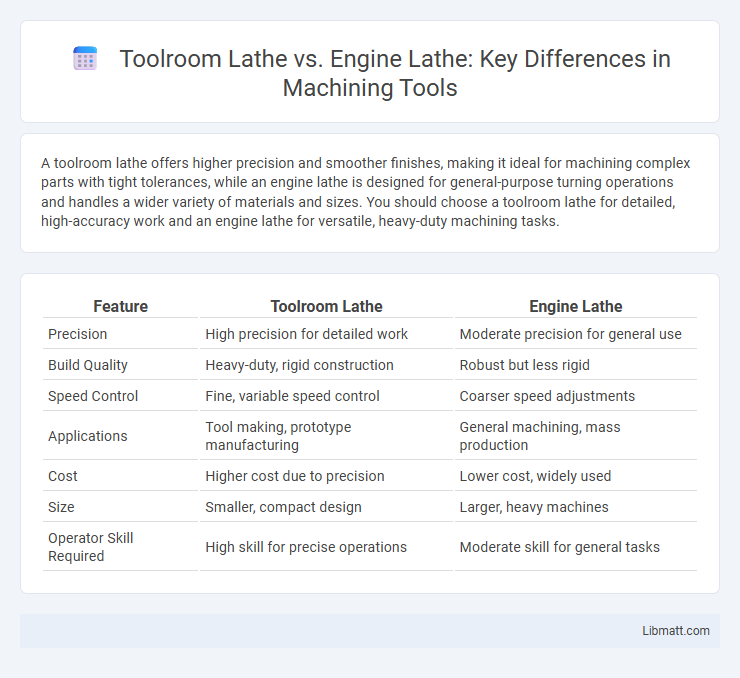

A toolroom lathe offers higher precision and smoother finishes, making it ideal for machining complex parts with tight tolerances, while an engine lathe is designed for general-purpose turning operations and handles a wider variety of materials and sizes. You should choose a toolroom lathe for detailed, high-accuracy work and an engine lathe for versatile, heavy-duty machining tasks.

Table of Comparison

| Feature | Toolroom Lathe | Engine Lathe |

|---|---|---|

| Precision | High precision for detailed work | Moderate precision for general use |

| Build Quality | Heavy-duty, rigid construction | Robust but less rigid |

| Speed Control | Fine, variable speed control | Coarser speed adjustments |

| Applications | Tool making, prototype manufacturing | General machining, mass production |

| Cost | Higher cost due to precision | Lower cost, widely used |

| Size | Smaller, compact design | Larger, heavy machines |

| Operator Skill Required | High skill for precise operations | Moderate skill for general tasks |

Overview of Toolroom Lathes and Engine Lathes

Toolroom lathes are precision machines designed for fine, intricate work, commonly used in prototyping and toolmaking, offering superior accuracy and smoother finishes. Engine lathes, built for general-purpose metalworking, provide robust performance with higher versatility, suitable for a wide range of turning operations in production environments. Both lathe types differ significantly in terms of precision, rigidity, and tooling capabilities, influencing their optimal applications in manufacturing and repair workshops.

Key Differences Between Toolroom and Engine Lathes

Toolroom lathes are designed for precision work and small batch production, featuring higher spindle speed accuracy, finer feed adjustments, and enhanced vibration control to achieve superior surface finishes. Engine lathes are built for general-purpose machining, offering robust construction and versatility for heavy-duty tasks with less emphasis on ultra-fine tolerances. Toolroom lathes typically include features such as tapered roller bearings and higher-quality slideways, whereas engine lathes prioritize power and capacity for larger workpieces.

Construction and Design Features

Toolroom lathes feature precision-ground ways, hardened bed surfaces, and finer feed mechanisms designed for high accuracy and smooth finishes, making them ideal for intricate and detailed work. Engine lathes have robust, heavier construction with standard cast iron beds and less precise feed systems, suited for general-purpose turning and heavy-duty machining tasks. Your choice depends on whether you prioritize precision engineering or versatility and durability in machining operations.

Precision and Accuracy Comparison

Toolroom lathes offer superior precision and accuracy compared to engine lathes due to their tighter spindle tolerances, higher-quality bearings, and finer feed controls. Engine lathes are more suited for general-purpose machining but may lack the exacting detail required for high-precision tasks. Choosing a toolroom lathe ensures your work benefits from consistent repeatability and precise dimensional control.

Typical Applications in Industry

Toolroom lathes are primarily used in precision engineering, prototyping, and tool making due to their high accuracy and fine surface finish capabilities, making them ideal for producing intricate components and small batch runs. Engine lathes find widespread application in general machining tasks such as turning, facing, and threading of larger workpieces, commonly used in automotive repair, manufacturing, and maintenance workshops. Industries including aerospace, mold making, and die sinking often rely on toolroom lathes for detailed work, whereas engine lathes serve metal fabrication, heavy equipment, and shipbuilding sectors with their robust performance.

Speed and Power Capabilities

Toolroom lathes typically offer higher precision at moderate speeds with variable speed controls suited for delicate work, whereas engine lathes provide greater power and higher speed ranges ideal for heavy-duty cutting and larger workpieces. The power capabilities of engine lathes include robust motors ranging from 5 to 15 horsepower, enabling them to handle tougher materials and extended operation times. Speed in toolroom lathes generally maxes out around 2,000 RPM for fine machining, while engine lathes can reach speeds exceeding 3,000 RPM to maximize material removal rates.

Tooling and Accessories Compatibility

Toolroom lathes offer superior tooling and accessories compatibility with precision attachments, collets, and quick-change tool posts designed for intricate and high-accuracy work. Engine lathes support a broader range of general-purpose tooling, including standard chucks and basic tool holders, suitable for heavy-duty and variable-speed operations. The specialized tooling adaptability of toolroom lathes enhances fine machining tasks, while engine lathes provide versatile accessory interchangeability for more robust industrial applications.

Maintenance and Operational Requirements

Toolroom lathes require precise maintenance with regular lubrication and calibration to maintain high accuracy for fine tolerance work, while engine lathes have more robust construction demanding less frequent, though thorough, maintenance to handle heavy-duty machining. Operationally, toolroom lathes are designed for delicate, intricate tasks, requiring skilled operators to ensure precision, whereas engine lathes support versatile, high-volume production with simpler operational procedures. Effective maintenance schedules and operator training optimize performance and longevity for both lathe types in industrial settings.

Cost and Investment Considerations

Toolroom lathes generally require a higher initial investment due to their precision engineering and advanced features, making them suitable for specialized, high-accuracy tasks. Engine lathes present a more cost-effective option, ideal for general-purpose machining with lower upfront expenses and simpler maintenance. Businesses must balance precision needs against budget constraints when choosing between the two lathe types.

Choosing the Right Lathe for Your Workshop

Toolroom lathes offer high precision and fine surface finishes, ideal for detailed, intricate work requiring tight tolerances, while engine lathes provide versatility and higher power suitable for general metalworking tasks and larger workpieces. Your workshop benefits from selecting a toolroom lathe if precision and repeatability are critical, whereas an engine lathe suits varied machining processes and heavy-duty cutting. Evaluating the complexity of your projects and production volume helps determine which lathe delivers optimal performance and efficiency.

Toolroom lathe vs engine lathe Infographic

libmatt.com

libmatt.com