Hex wrenches feature a simple six-sided design ideal for standard fasteners, offering ease of use in tight spaces. Torx wrenches provide a star-shaped pattern that reduces cam-out and allows your tools to apply greater torque, making them better suited for high-torque applications.

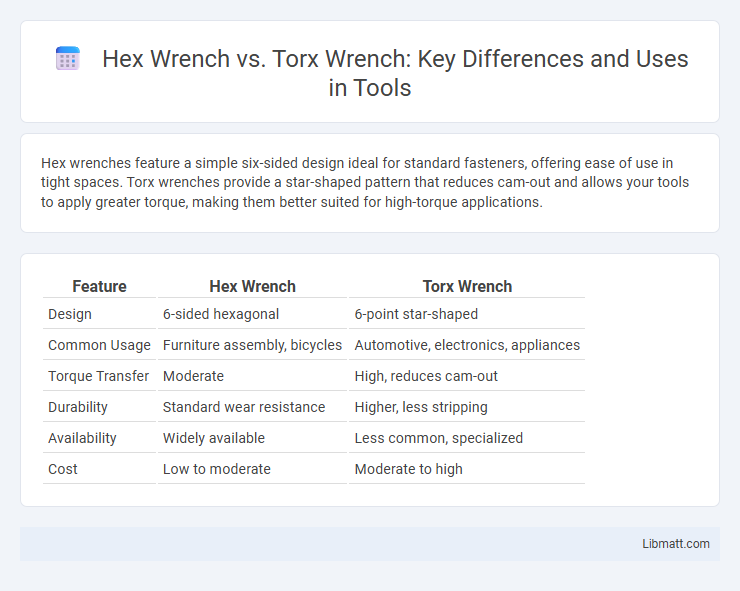

Table of Comparison

| Feature | Hex Wrench | Torx Wrench |

|---|---|---|

| Design | 6-sided hexagonal | 6-point star-shaped |

| Common Usage | Furniture assembly, bicycles | Automotive, electronics, appliances |

| Torque Transfer | Moderate | High, reduces cam-out |

| Durability | Standard wear resistance | Higher, less stripping |

| Availability | Widely available | Less common, specialized |

| Cost | Low to moderate | Moderate to high |

Introduction: Hex Wrench vs. Torx Wrench

Hex wrenches feature a six-sided hexagonal shape, ideal for applications requiring moderate torque and common in furniture assembly and bicycle maintenance. Torx wrenches have a star-shaped, six-point design providing superior grip and torque transfer, reducing cam-out in automotive and electronic repairs. Choosing the right wrench ensures Your tools match the fastener type, improving efficiency and preventing damage.

What Is a Hex Wrench?

A hex wrench, also known as an Allen wrench or hex key, is a simple tool designed to drive bolts and screws with hexagonal (six-sided) recesses in their heads. It provides excellent torque and grip due to its shape, making it ideal for assembling furniture, machinery, and bicycles. Your choice of a hex wrench ensures precise fitting for hex socket screws, minimizing the risk of stripping or damaging fasteners.

What Is a Torx Wrench?

A Torx wrench is a tool designed to fit Torx screws, characterized by a six-point star-shaped pattern that provides superior grip and torque transfer compared to traditional hex wrenches. Unlike hex wrenches, which feature a simple six-sided design, Torx wrenches reduce cam-out and wear, making them ideal for automotive, electronics, and manufacturing applications. The precision-engineered star shape ensures better alignment and less stripping, enhancing the durability and reliability of fastened components.

Design Differences Between Hex and Torx Wrenches

Hex wrenches feature a simple six-sided design that fits hexagonal bolts, providing basic grip and torque capabilities. Torx wrenches have a star-shaped, six-pointed pattern designed to increase contact area between tool and fastener, reducing cam-out and allowing for higher torque application. Your choice between Hex and Torx wrenches depends on the type of fastener and required precision in fastening tasks.

Common Applications of Hex Wrenches

Hex wrenches are commonly used in assembling flat-pack furniture, tightening bicycle components, and securing automotive parts due to their simple hexagonal socket design. They provide precise torque control for fasteners such as socket head cap screws and bolts found in machinery and electronics. This versatility makes hex wrenches essential in both DIY projects and professional mechanical maintenance.

Typical Uses for Torx Wrenches

Torx wrenches are commonly used in automotive, electronics, and appliance assembly due to their ability to provide better torque transfer and reduce cam-out compared to hex wrenches. These tools are favored for securing fasteners in high-torque applications, such as engine components and computer hardware, where precision and durability are critical. Their star-shaped design distributes force evenly, making them ideal for manufacturing environments requiring consistent and reliable fastening.

Advantages of Hex Wrenches

Hex wrenches offer superior simplicity and cost-effectiveness due to their universal design, making them widely compatible with a variety of fasteners, especially in furniture assembly and bicycle maintenance. Their six-sided shape provides excellent grip and torque control, reducing the risk of stripping screws compared to other wrench types. The compact, L-shaped design enhances accessibility in tight spaces, making hex wrenches a versatile and durable choice for both professional mechanics and DIY enthusiasts.

Benefits of Torx Wrenches

Torx wrenches provide superior grip and torque transfer compared to hex wrenches, reducing the risk of cam-out and tool slippage during use. Their star-shaped design distributes force more evenly across fasteners, enhancing durability and minimizing wear on both tools and screws. Choosing a Torx wrench for your projects ensures increased precision and efficiency, especially in applications requiring high torque.

Which Wrench is Better for Your Project?

Hex wrenches provide excellent grip on hexagonal fasteners, making them ideal for general mechanical and furniture assembly projects, while Torx wrenches offer superior torque and reduce cam-out on star-shaped fasteners, often preferred in automotive and electronics repairs. Choosing between the two depends on the fastener type and the need for precision or torque; Torx wrenches excel in high-torque applications, whereas hex wrenches deliver versatility and ease of use for common tasks. Evaluating the fastener design and project requirements ensures the best fit, maximizing efficiency and minimizing tool wear.

Conclusion: Choosing the Right Wrench

Choosing the right wrench depends on the specific application and fastener type; Hex wrenches are ideal for Allen screws with six-sided recesses, offering versatility in general assembly and maintenance tasks. Torx wrenches, featuring a star-shaped pattern, provide superior grip and reduce cam-out on fasteners commonly found in automotive and electronics industries. Your tool selection should prioritize compatibility with the fastener design to ensure efficient torque application and prevent damage.

Hex wrench vs Torx wrench Infographic

libmatt.com

libmatt.com