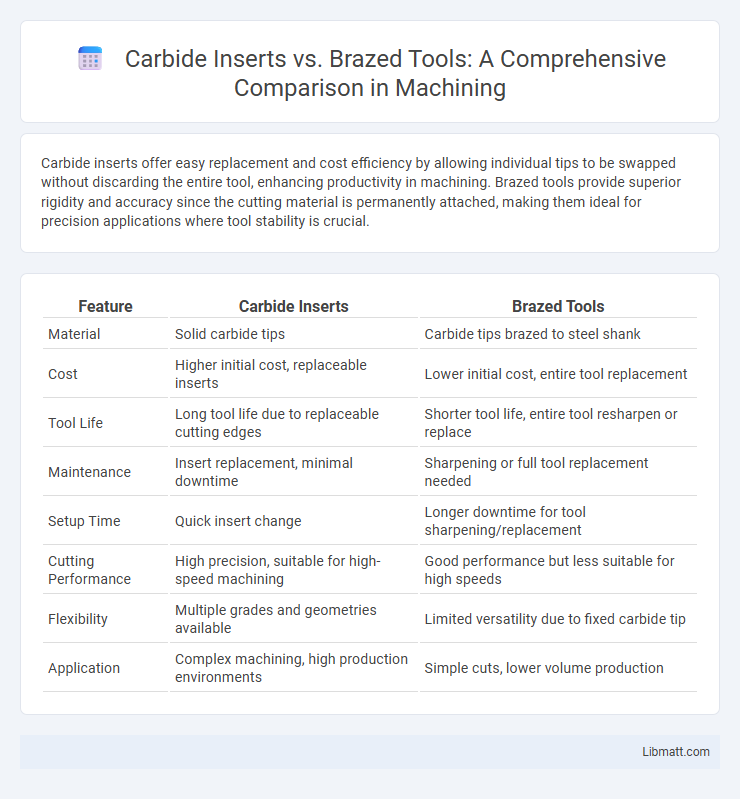

Carbide inserts offer easy replacement and cost efficiency by allowing individual tips to be swapped without discarding the entire tool, enhancing productivity in machining. Brazed tools provide superior rigidity and accuracy since the cutting material is permanently attached, making them ideal for precision applications where tool stability is crucial.

Table of Comparison

| Feature | Carbide Inserts | Brazed Tools |

|---|---|---|

| Material | Solid carbide tips | Carbide tips brazed to steel shank |

| Cost | Higher initial cost, replaceable inserts | Lower initial cost, entire tool replacement |

| Tool Life | Long tool life due to replaceable cutting edges | Shorter tool life, entire tool resharpen or replace |

| Maintenance | Insert replacement, minimal downtime | Sharpening or full tool replacement needed |

| Setup Time | Quick insert change | Longer downtime for tool sharpening/replacement |

| Cutting Performance | High precision, suitable for high-speed machining | Good performance but less suitable for high speeds |

| Flexibility | Multiple grades and geometries available | Limited versatility due to fixed carbide tip |

| Application | Complex machining, high production environments | Simple cuts, lower volume production |

Introduction to Carbide Inserts and Brazed Tools

Carbide inserts are cutting tool components made from tungsten carbide, prized for their hardness and wear resistance, enabling efficient metalworking in high-speed applications. Brazed tools consist of a carbide tip permanently bonded to a steel shank, providing a strong, stable cutting edge ideal for precision machining and heavy-duty tasks. Both tools offer distinct advantages in tooling performance, with carbide inserts favored for easy replacement and brazed tools valued for rigidity and durability.

Material Composition and Manufacturing Process

Carbide inserts consist primarily of tungsten carbide particles bonded with cobalt, providing exceptional hardness and wear resistance through a powder metallurgy process involving sintering at high temperatures. Brazed tools feature a single, solid carbide tip that is metallurgically joined to the steel shank via a high-temperature brazing process, ensuring a strong, precise bond. Your choice between carbide inserts and brazed tools depends on the desired balance of replaceability, manufacturing complexity, and performance in demanding machining operations.

Performance and Cutting Efficiency

Carbide inserts offer superior performance and cutting efficiency due to their hardness and resistance to wear, enabling higher cutting speeds and longer tool life compared to brazed tools. Brazed tools, while cost-effective and rigid, typically require more frequent sharpening and cannot match the precision or productivity of carbide inserts in high-demand machining operations. Choosing carbide inserts can significantly enhance Your manufacturing throughput and surface finish quality, especially in challenging materials and high-volume production.

Tool Life and Durability

Carbide inserts offer superior tool life and durability compared to brazed tools due to their enhanced wear resistance and ability to maintain cutting edge sharpness under high temperatures. Brazed tools, while cost-effective, tend to have a shorter lifespan because the cutting edge is permanently attached and more susceptible to chipping or breaking. Your machining performance can significantly benefit from carbide inserts, which reduce downtime and tool changes, leading to increased productivity.

Cost Comparison and Economic Considerations

Carbide inserts generally involve higher initial costs compared to brazed tools but offer longer tool life and easier replaceability, reducing downtime and maintenance expenses. Brazed tools come with lower upfront investment, making them economically viable for short production runs or budget-conscious operations. Your choice between carbide inserts and brazed tools should factor in total operational costs, including tooling frequency, machine downtime, and productivity impact.

Versatility and Application Range

Carbide inserts offer exceptional versatility with their ability to fit multiple tool holders and accommodate various cutting geometries, making them ideal for a broad range of applications from roughing to finishing. Brazed tools, while providing superior strength and rigidity, are typically limited to specific machining tasks and materials due to their fixed cutting edge. Your choice between carbide inserts and brazed tools will depend on the desired flexibility and the specific requirements of your machining operations.

Ease of Replacement and Maintenance

Carbide inserts offer significant ease of replacement and maintenance compared to brazed tools since they can be quickly swapped without removing the entire tool holder, minimizing machine downtime. Brazed tools require grinding or re-sharpening once worn, involving more time-consuming maintenance and precision handling. Your production efficiency improves with carbide inserts due to reduced tool changeover times and straightforward maintenance protocols.

Surface Finish and Machining Accuracy

Carbide inserts offer superior surface finish and machining accuracy due to their precision-ground edges and resistance to wear, which maintain consistent cutting performance over prolonged use. Brazed tools generally provide less consistent surface quality because the tool material is harder to control during manufacturing, leading to potential variations in edge sharpness and dimensional accuracy. Choosing carbide inserts can enhance your machining process by delivering smoother finishes and tighter tolerances on complex or high-precision components.

Environmental Impact and Waste Reduction

Carbide inserts significantly reduce environmental impact due to their longer tool life and recyclability, minimizing metal waste compared to brazed tools which often require full replacement upon wear. The modularity of carbide inserts allows for selective replacement of worn cutting edges, lowering material consumption and reducing manufacturing scrap. These factors collectively contribute to sustainable machining practices by decreasing resource usage and promoting efficient waste management.

Choosing the Right Tool for Your Machining Needs

Carbide inserts offer superior wear resistance and easy replacement, making them ideal for high-volume machining and diverse materials. Brazed tools provide a rigid cutting edge with lower changeover costs, best suited for steady, repetitive operations on stable workpieces. Selecting the right tool hinges on balancing cutting performance, cost-efficiency, and machining complexity specific to your production goals.

Carbide inserts vs brazed tool Infographic

libmatt.com

libmatt.com