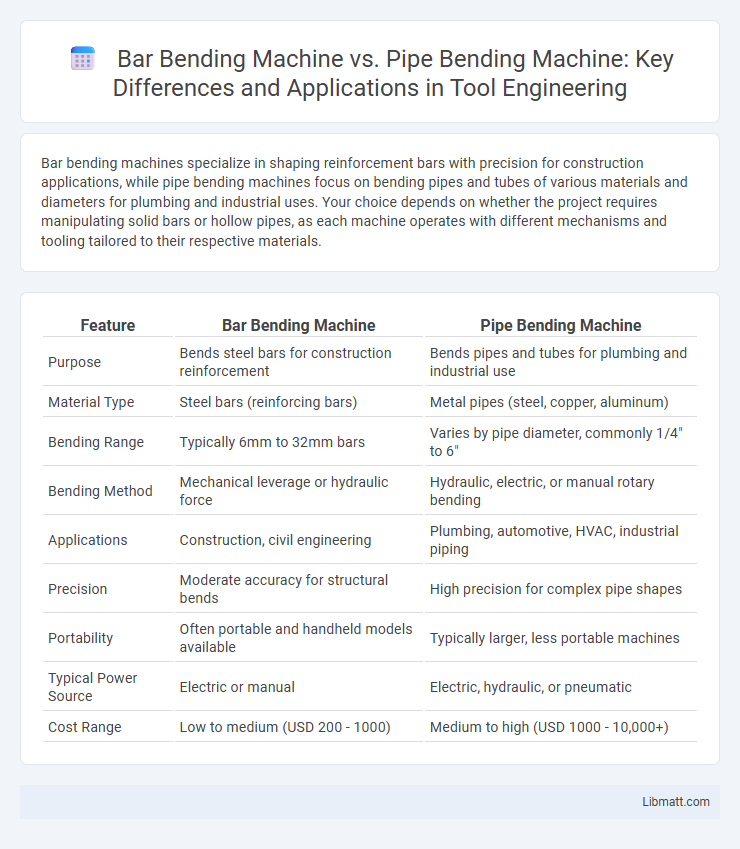

Bar bending machines specialize in shaping reinforcement bars with precision for construction applications, while pipe bending machines focus on bending pipes and tubes of various materials and diameters for plumbing and industrial uses. Your choice depends on whether the project requires manipulating solid bars or hollow pipes, as each machine operates with different mechanisms and tooling tailored to their respective materials.

Table of Comparison

| Feature | Bar Bending Machine | Pipe Bending Machine |

|---|---|---|

| Purpose | Bends steel bars for construction reinforcement | Bends pipes and tubes for plumbing and industrial use |

| Material Type | Steel bars (reinforcing bars) | Metal pipes (steel, copper, aluminum) |

| Bending Range | Typically 6mm to 32mm bars | Varies by pipe diameter, commonly 1/4" to 6" |

| Bending Method | Mechanical leverage or hydraulic force | Hydraulic, electric, or manual rotary bending |

| Applications | Construction, civil engineering | Plumbing, automotive, HVAC, industrial piping |

| Precision | Moderate accuracy for structural bends | High precision for complex pipe shapes |

| Portability | Often portable and handheld models available | Typically larger, less portable machines |

| Typical Power Source | Electric or manual | Electric, hydraulic, or pneumatic |

| Cost Range | Low to medium (USD 200 - 1000) | Medium to high (USD 1000 - 10,000+) |

Introduction to Bending Machines

Bending machines are essential tools in metal fabrication, designed to shape materials into specific angles or curves. Bar bending machines primarily handle steel bars and rods, commonly used in construction for reinforcing concrete structures. Pipe bending machines specialize in curving pipes and tubes without compromising their structural integrity, vital in plumbing, automotive, and industrial applications.

What is a Bar Bending Machine?

A bar bending machine is a specialized tool designed for shaping steel bars and rebars used in construction, enhancing precision and efficiency in bending operations. It operates with adjustable settings to bend bars at specific angles, crucial for reinforcing concrete structures. Unlike pipe bending machines, which are tailored for tubular materials, bar bending machines handle solid steel rods, providing consistent bends without compromising material integrity.

What is a Pipe Bending Machine?

A pipe bending machine is a specialized device designed to shape pipes and tubes into precise angles and curves without compromising structural integrity. It utilizes various bending methods such as rotary draw, roll bending, or compression to form metal pipes used in construction, automotive, and plumbing industries. Unlike bar bending machines that focus on reinforcing bars, pipe bending machines handle hollow sections for custom fabrication and installation.

Key Differences Between Bar and Pipe Bending Machines

Bar bending machines are specifically designed to bend reinforced steel bars used in construction, offering precise angles and consistent shapes for rebar. Pipe bending machines, on the other hand, handle various diameters of metal pipes, providing smooth, continuous bends without collapsing or deforming the pipe structure. Understanding these key differences helps you select the right machine for your project's material and bending requirements.

Applications of Bar Bending Machines

Bar bending machines are primarily used in construction and civil engineering projects for shaping steel bars and rebars into various angles and curves required for reinforcing concrete structures. These machines efficiently bend metal bars for beams, columns, foundations, and slabs, ensuring structural integrity in buildings, bridges, and highways. Unlike pipe bending machines that shape hollow pipes for plumbing, automotive, and industrial applications, bar bending machines focus on solid reinforcement materials essential for load-bearing frameworks.

Applications of Pipe Bending Machines

Pipe bending machines are extensively used in industries such as construction, automotive, aerospace, and shipbuilding, where precise bending of pipes is essential for creating structural components, exhaust systems, and hydraulic lines. These machines accommodate various pipe materials, including stainless steel, copper, and aluminum, enabling customized shapes and angles without compromising material integrity. Versatile in function, pipe bending machines enhance manufacturing efficiency by producing consistent bends for pipelines, furniture frames, and architectural elements.

Performance and Efficiency Comparison

Bar bending machines excel in bending steel bars with high precision and rapid cycle times, making them ideal for construction projects requiring consistent rebar shapes. Pipe bending machines offer greater versatility by handling various pipe diameters and materials, optimizing efficiency in industrial applications needing complex bend angles. Your choice depends on whether you prioritize speed and uniformity for bars or flexibility and adaptability for pipes.

Material Compatibility and Versatility

Bar bending machines excel in shaping steel bars and rebars, providing precise bends for construction and infrastructure projects. Pipe bending machines are designed to handle a broader range of materials, including steel, copper, aluminum, and stainless steel pipes, offering greater versatility for plumbing, automotive, and industrial applications. While bar bending machines specialize in heavy-duty reinforcement materials, pipe bending machines accommodate various pipe diameters and wall thicknesses, ensuring adaptability across multiple industries.

Cost Analysis: Bar vs Pipe Bending Machines

Bar bending machines generally have lower upfront costs compared to pipe bending machines due to simpler mechanical components and lower power requirements. Pipe bending machines often entail higher expenses because of advanced features needed to handle various pipe diameters, thicknesses, and bending radii with precision. Maintenance and operational costs for pipe bending machines can also exceed those of bar bending machines, driven by more complex tooling and calibration processes.

Which Bending Machine Should You Choose?

Choosing between a bar bending machine and a pipe bending machine depends on the material and application requirements. Bar bending machines excel at shaping steel bars used in construction reinforcement, offering precise angles and heavy-duty performance. Pipe bending machines are ideal for shaping hollow tubes and pipes in plumbing, automotive, and structural frameworks, providing smooth bends without compromising pipe integrity.

Bar bending machine vs pipe bending machine Infographic

libmatt.com

libmatt.com