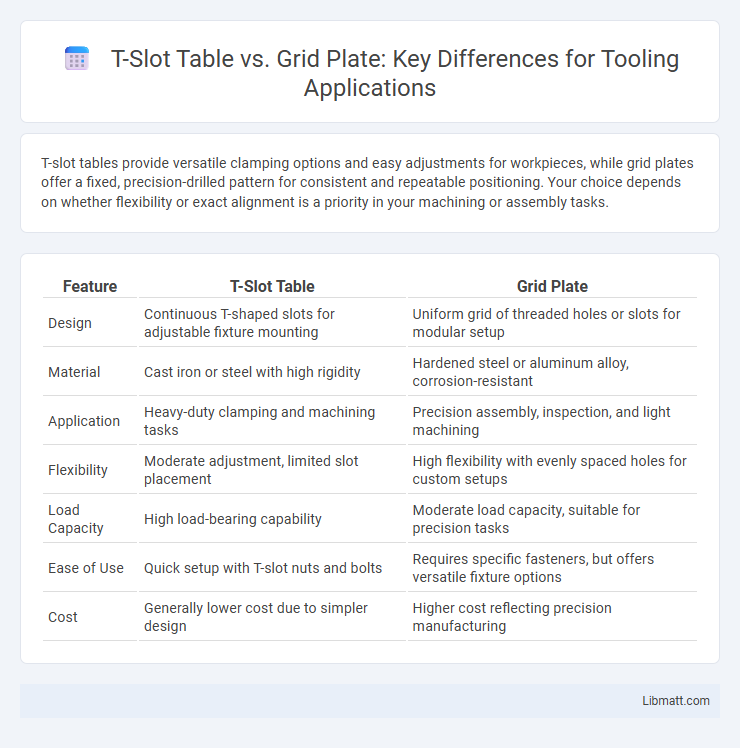

T-slot tables provide versatile clamping options and easy adjustments for workpieces, while grid plates offer a fixed, precision-drilled pattern for consistent and repeatable positioning. Your choice depends on whether flexibility or exact alignment is a priority in your machining or assembly tasks.

Table of Comparison

| Feature | T-Slot Table | Grid Plate |

|---|---|---|

| Design | Continuous T-shaped slots for adjustable fixture mounting | Uniform grid of threaded holes or slots for modular setup |

| Material | Cast iron or steel with high rigidity | Hardened steel or aluminum alloy, corrosion-resistant |

| Application | Heavy-duty clamping and machining tasks | Precision assembly, inspection, and light machining |

| Flexibility | Moderate adjustment, limited slot placement | High flexibility with evenly spaced holes for custom setups |

| Load Capacity | High load-bearing capability | Moderate load capacity, suitable for precision tasks |

| Ease of Use | Quick setup with T-slot nuts and bolts | Requires specific fasteners, but offers versatile fixture options |

| Cost | Generally lower cost due to simpler design | Higher cost reflecting precision manufacturing |

Introduction to T-Slot Tables and Grid Plates

T-slot tables offer versatile clamping options with parallel slots designed for adjustable fixturing in machining and assembly processes. Grid plates feature a matrix of threaded holes arranged in a precise grid pattern, enabling flexible mounting and alignment of components for inspection or tooling setups. Your choice between a T-slot table and a grid plate depends on specific application requirements, such as fixture adaptability and load distribution.

Key Features of T-Slot Tables

T-slot tables feature parallel slots that allow flexible mounting of clamps and fixtures for precise workpiece positioning in machining and assembly tasks. Their robust aluminum or cast iron construction offers high load capacity and vibration dampening, enhancing accuracy and durability. Unlike grid plates with evenly spaced holes, T-slot tables provide adjustable, linear slot configurations that support diverse tooling setups and simplified alignment.

Key Features of Grid Plates

Grid plates feature a uniform pattern of threaded holes spaced at precise intervals, enabling flexible fixturing and quick setup adjustments. Unlike T-slot tables, grid plates provide a flat, void-free surface that enhances accuracy and stability during machining or inspection processes. Your choice of grid plates ensures modularity and compatibility with a wide range of workholding accessories for versatile manufacturing applications.

Applications of T-Slot Tables

T-slot tables are commonly used in machining and fabrication for securely mounting workpieces with adjustable clamps during milling, drilling, and welding operations. Their versatility allows precise repositioning of fixtures, making them ideal for custom setups in metalworking, woodworking, and assembly tasks. T-slot tables enhance workflow efficiency by enabling quick changeovers and strong hold-down capabilities on CNC machines and manual workbenches.

Applications of Grid Plates

Grid plates excel in precision assembly and inspection tasks across aerospace, automotive, and electronics industries, providing a flat, stable surface with a dense array of threaded holes for flexible fixturing. Their modular design supports accurate positioning of components during machining, welding, and quality control processes, ensuring repeatability and efficiency. Used extensively in coordinate measuring machines (CMM) and metrology labs, grid plates enable high-precision alignment and measurement critical to advanced manufacturing workflows.

Advantages of T-Slot Tables

T-slot tables offer superior versatility and secure workholding due to their adjustable slot spacing, accommodating various fixture sizes and shapes. Their continuous grooves enable quick and precise positioning of clamps, enhancing machining accuracy and workflow efficiency. Unlike grid plates, T-slot tables are easier to clean and maintain, reducing downtime in industrial applications.

Advantages of Grid Plates

Grid plates offer enhanced versatility in fixture setup due to their uniform hole pattern, enabling precise and repeatable positioning of components. Their flat surface minimizes setup errors and simplifies alignment processes, making them ideal for complex manufacturing and inspection tasks. The modularity of grid plates supports rapid reconfiguration, significantly reducing downtime during production changes.

Limitations and Drawbacks

T-slot tables often face limitations in clamping flexibility and precision positioning due to fixed slot spacing, which can restrict customization for complex workpieces. Grid plates, while offering enhanced modularity and precise location options, may incur higher costs and require more setup time for optimal use. Your choice depends on balancing ease of use against the need for adaptability and accuracy in specific machining or assembly operations.

Factors to Consider When Choosing

When choosing between a T-slot table and a grid plate, consider the type of workpiece and tooling, as the T-slot table offers flexible clamping options for varied setups, while a grid plate provides precise, repeatable positioning ideal for high-accuracy machining. Evaluate the load capacity and rigidity requirements, since T-slot tables typically support heavier loads but may have lower positional accuracy compared to the finely machined holes of grid plates. Cost and ease of customization also impact decision-making; T-slot tables are generally more affordable and adaptable, whereas grid plates require a more detailed initial layout but enhance long-term efficiency for repetitive tasks.

Conclusion: T-Slot Table vs Grid Plate

T-slot tables provide greater versatility and ease of clamping for machining and assembly due to adjustable slots designed for various fixture attachments. Grid plates offer enhanced precision and repeatability with uniform hole patterns best suited for exact positioning and modular tooling systems. Choosing between the two depends on whether flexibility or high-precision alignment is the primary requirement in the manufacturing process.

T-slot table vs grid plate Infographic

libmatt.com

libmatt.com