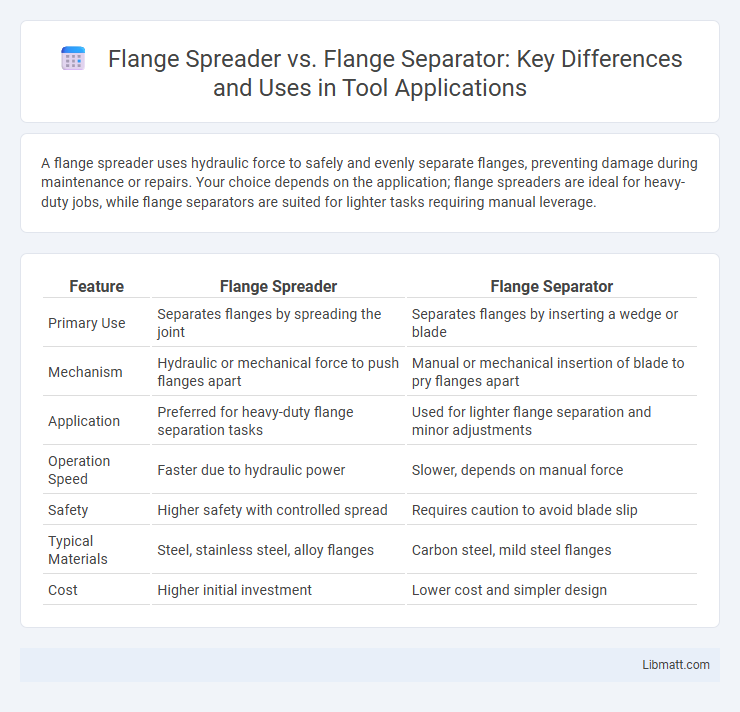

A flange spreader uses hydraulic force to safely and evenly separate flanges, preventing damage during maintenance or repairs. Your choice depends on the application; flange spreaders are ideal for heavy-duty jobs, while flange separators are suited for lighter tasks requiring manual leverage.

Table of Comparison

| Feature | Flange Spreader | Flange Separator |

|---|---|---|

| Primary Use | Separates flanges by spreading the joint | Separates flanges by inserting a wedge or blade |

| Mechanism | Hydraulic or mechanical force to push flanges apart | Manual or mechanical insertion of blade to pry flanges apart |

| Application | Preferred for heavy-duty flange separation tasks | Used for lighter flange separation and minor adjustments |

| Operation Speed | Faster due to hydraulic power | Slower, depends on manual force |

| Safety | Higher safety with controlled spread | Requires caution to avoid blade slip |

| Typical Materials | Steel, stainless steel, alloy flanges | Carbon steel, mild steel flanges |

| Cost | Higher initial investment | Lower cost and simpler design |

Introduction to Flange Tools

Flange spreaders and flange separators are essential tools used to safely and efficiently create space between flanges during maintenance or assembly in piping systems. Flange spreaders typically use a wedge or hydraulic mechanism to evenly spread flange faces, minimizing damage to gaskets and flanges, while flange separators primarily focus on prying apart flanges with leverage-based tools. Choosing the right flange tool depends on your specific application, flange size, and the need for controlled separation to ensure safe and effective operations.

What is a Flange Spreader?

A flange spreader is a hydraulic tool designed to safely and efficiently separate flanges during maintenance or repair operations, minimizing the risk of damage. It features a wedge or blade that inserts between flange faces to apply controlled force, allowing for even and precise separation. Commonly used in pipeline and industrial applications, flange spreaders improve safety and reduce downtime compared to traditional methods.

What is a Flange Separator?

A flange separator is a hydraulic tool designed to create space between two flange faces for maintenance or repair tasks, ensuring safe and efficient separation without damaging the flange components. Unlike flange spreaders, flange separators typically use a wedge mechanism to gently pry open tight or rusted flanges, minimizing risk of flange distortion. Your choice between a flange separator and a flange spreader depends on the flange condition and the precision required for the separation process.

Key Differences Between Flange Spreaders and Separators

Flange spreaders use hydraulic power to exert controlled force, safely creating space between flanges for maintenance, making them ideal for heavy-duty industrial applications. Flange separators, usually mechanical tools, rely on manual leverage to pry flanges apart, suitable for lighter tasks and tighter spaces. Understanding these distinctions helps you select the right tool for efficient flange maintenance and repair.

Common Applications for Flange Spreaders

Flange spreaders are commonly used in pipe maintenance and repair to safely separate flange joints for gasket replacement, inspection, and cleaning without causing damage to the flange faces. They are essential in industries like oil and gas, chemical processing, and power generation, where precise and controlled flange separation minimizes downtime and ensures worker safety. Unlike flange separators, flange spreaders provide a gradual, uniform expansion to prevent deformation, making them ideal for delicate or heavily tightened flange connections.

Typical Uses of Flange Separators

Flange separators are primarily used for disassembling flanged joints in pipelines, particularly during maintenance, repair, and inspection tasks in industries like oil and gas, petrochemical, and water treatment. They safely create space between flange faces to remove gaskets or facilitate bolt removal without causing damage to the flange surfaces. The precision and controlled spreading force of flange separators make them essential tools for ensuring the integrity and longevity of pipeline systems.

Advantages of Using a Flange Spreader

Flange spreaders offer precise control and safety when separating flanges by applying even hydraulic pressure, reducing the risk of damaging the flange face or gasket. Their compact and efficient design allows for work in confined spaces, making them ideal for maintenance tasks in tight industrial environments. Using a flange spreader can increase productivity and ensure consistent flange separation, protecting your equipment and reducing downtime.

Benefits of a Flange Separator

A flange separator provides precise and controlled separation of flanges, reducing the risk of damage to piping systems during maintenance or repair. Its compact design enables easy access in confined spaces where traditional flange spreaders might not fit effectively. By evenly distributing force across the flange, flange separators minimize alignment issues and enhance safety for operators during disassembly.

Safety Considerations for Both Tools

Flange spreaders and flange separators each have specific safety considerations critical to preventing injury and equipment damage during use. Flange spreaders require careful positioning to avoid slipping under high pressure, while flange separators must be used with appropriate force to prevent sudden releases or flange distortion. Ensuring your tools are properly maintained and using personal protective equipment can significantly enhance operational safety with both devices.

Choosing the Right Tool: Flange Spreader vs Flange Separator

Choosing the right tool for flange maintenance depends on your specific application: a flange spreader uses hydraulic force to safely and evenly separate flanges without damaging the gasket, making it ideal for precise industrial use. In contrast, a flange separator is a manual tool designed to wedge between flanges, better suited for quick, less delicate jobs but with a higher risk of damaging components. Understanding these differences ensures your flange work is efficient and protects the integrity of your piping system.

Flange spreader vs flange separator Infographic

libmatt.com

libmatt.com