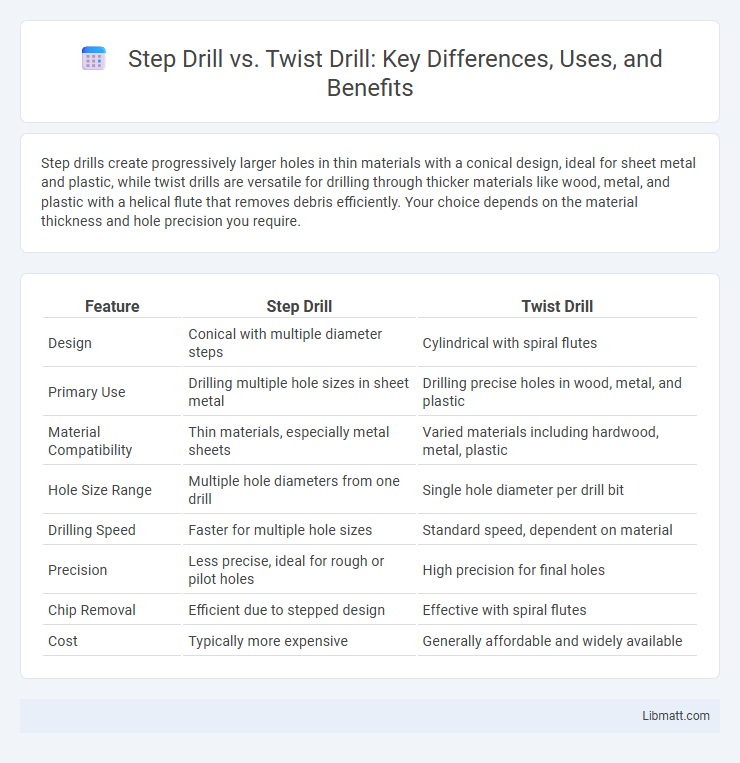

Step drills create progressively larger holes in thin materials with a conical design, ideal for sheet metal and plastic, while twist drills are versatile for drilling through thicker materials like wood, metal, and plastic with a helical flute that removes debris efficiently. Your choice depends on the material thickness and hole precision you require.

Table of Comparison

| Feature | Step Drill | Twist Drill |

|---|---|---|

| Design | Conical with multiple diameter steps | Cylindrical with spiral flutes |

| Primary Use | Drilling multiple hole sizes in sheet metal | Drilling precise holes in wood, metal, and plastic |

| Material Compatibility | Thin materials, especially metal sheets | Varied materials including hardwood, metal, plastic |

| Hole Size Range | Multiple hole diameters from one drill | Single hole diameter per drill bit |

| Drilling Speed | Faster for multiple hole sizes | Standard speed, dependent on material |

| Precision | Less precise, ideal for rough or pilot holes | High precision for final holes |

| Chip Removal | Efficient due to stepped design | Effective with spiral flutes |

| Cost | Typically more expensive | Generally affordable and widely available |

Introduction to Step Drills and Twist Drills

Step drills feature a conical shape with multiple diameters on a single bit, enabling efficient drilling of various hole sizes without changing tools. Twist drills consist of a cylindrical shaft with helical flutes designed for precise cutting and chip removal during hole drilling. Both tools are essential in metalworking and woodworking but differ significantly in application and efficiency.

Overview of Drill Bit Designs

Step drills feature a cone-shaped design with multiple diameters that progressively enlarge holes in thin materials, offering precision and versatility. Twist drills have a cylindrical shape with helical grooves designed to efficiently cut and remove material, suitable for a wide range of hole sizes and depths. Both designs optimize drilling performance by matching specific applications, material types, and hole requirements.

Material Compatibility: Step Drill vs Twist Drill

Step drills excel in cutting through thin materials like sheet metal, plastic, and aluminum due to their conical shape, which allows gradual hole enlargement without damaging the material. Twist drills are versatile and effective for drilling into tougher materials such as steel, wood, and fiberglass, but may cause more burrs and require pilot holes for larger diameters. Material compatibility depends on thickness and type; step drills are ideal for soft, thin materials, while twist drills handle a broader range of tougher, thicker materials with higher precision.

Hole Quality and Finish Comparison

Step drills produce cleaner holes with smoother edges due to their gradual cutting action, minimizing burrs and enhancing hole finish quality. Twist drills often leave rougher edges and require additional deburring, especially in thicker materials. Your choice between these drills depends on the precision needed for hole quality and the importance of reducing post-drilling finishing work.

Drilling Speed and Efficiency

Step drills provide superior drilling speed and efficiency when working with thin materials and sheet metals due to their ability to create multiple hole sizes in one pass, reducing tool changes. Twist drills perform better on thicker materials and harder metals, offering faster penetration rates but typically require separate bits for each hole diameter. Choosing between step and twist drills depends on material thickness and hole size requirements, with step drills excelling in high-speed, multi-size applications and twist drills optimized for conventional, single-diameter drilling tasks.

Versatility and Application Range

Step drills offer superior versatility for drilling tapered holes and enlarging existing holes in thin materials like sheet metal, making them ideal for electrical and automotive applications. Twist drills excel at drilling precise cylindrical holes in thicker materials such as wood, plastic, and metal, providing consistent depth control and a wide range of diameter sizes. The choice between step and twist drills depends on the specific application requirements, including material thickness and hole shape.

Cost Differences and Longevity

Step drills generally cost more upfront than twist drills due to their specialized design and materials, but their extended longevity and ability to drill multiple hole sizes without changing bits often result in lower overall expenses. Twist drills are typically cheaper initially but wear out faster, especially when used on harder materials, leading to more frequent replacements and higher long-term costs. Investing in a step drill can reduce tool replacement frequency and improve efficiency, making it a cost-effective choice for repetitive or diverse drilling tasks.

Ease of Use and Maintenance

Step drills offer greater ease of use due to their ability to drill multiple hole sizes with a single bit, reducing the need to change tools frequently. Twist drills require sharper edges and more frequent sharpening to maintain cutting efficiency, which can increase maintenance time and skill. Your choice depends on the balance between versatility and the level of upkeep you prefer.

Safety Considerations for Both Drill Types

Step drills and twist drills each require specific safety precautions to prevent accidents and ensure optimal performance. Step drills demand careful control to avoid catching or sudden torque reactions due to their larger cutting surface, while twist drills necessitate proper clamping and slower feed rates to prevent bit breakage and overheating. Using appropriate personal protective equipment (PPE) such as safety goggles, gloves, and securing workpieces firmly are essential safety measures for both drill types.

Choosing the Right Drill Bit for Your Project

Step drills offer precise hole sizing and clean edges, ideal for thin materials like sheet metal, while twist drills excel in versatility for thicker, tougher materials such as wood and metal. Selecting the right drill bit depends on the material thickness, hole diameter range, and desired finish quality, with step drills providing multiple hole sizes in one bit and twist drills delivering deeper, more robust holes. Understanding project requirements ensures optimal performance and extends bit lifespan by minimizing wear and overheating.

Step drill vs twist drill Infographic

libmatt.com

libmatt.com