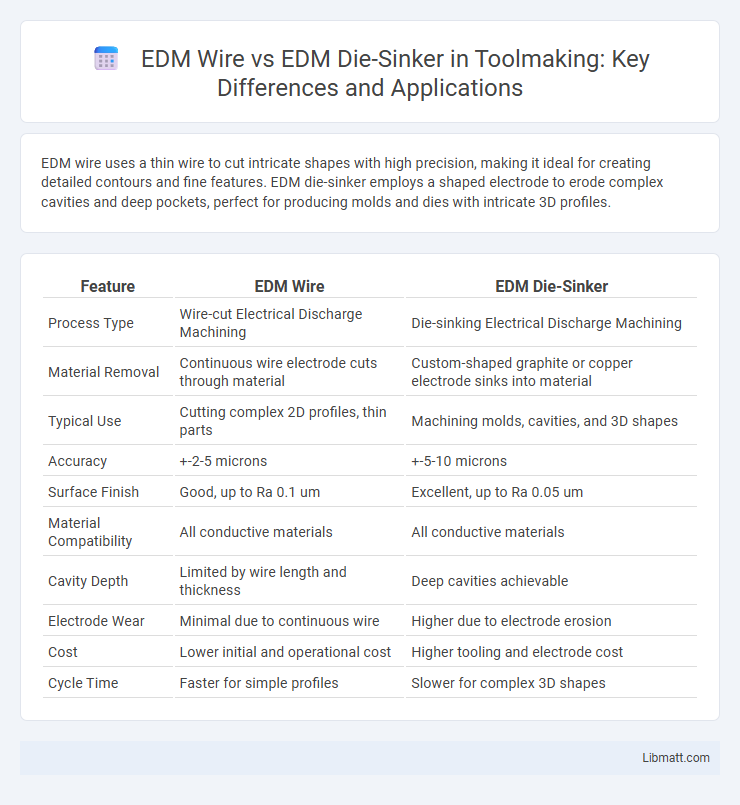

EDM wire uses a thin wire to cut intricate shapes with high precision, making it ideal for creating detailed contours and fine features. EDM die-sinker employs a shaped electrode to erode complex cavities and deep pockets, perfect for producing molds and dies with intricate 3D profiles.

Table of Comparison

| Feature | EDM Wire | EDM Die-Sinker |

|---|---|---|

| Process Type | Wire-cut Electrical Discharge Machining | Die-sinking Electrical Discharge Machining |

| Material Removal | Continuous wire electrode cuts through material | Custom-shaped graphite or copper electrode sinks into material |

| Typical Use | Cutting complex 2D profiles, thin parts | Machining molds, cavities, and 3D shapes |

| Accuracy | +-2-5 microns | +-5-10 microns |

| Surface Finish | Good, up to Ra 0.1 um | Excellent, up to Ra 0.05 um |

| Material Compatibility | All conductive materials | All conductive materials |

| Cavity Depth | Limited by wire length and thickness | Deep cavities achievable |

| Electrode Wear | Minimal due to continuous wire | Higher due to electrode erosion |

| Cost | Lower initial and operational cost | Higher tooling and electrode cost |

| Cycle Time | Faster for simple profiles | Slower for complex 3D shapes |

Introduction to EDM Wire and EDM Die-Sinker

EDM Wire and EDM Die-Sinker are two advanced electrical discharge machining techniques primarily used for precision metal cutting and shaping. EDM Wire utilizes a continuous thin wire as an electrode to cut complex contours and fine details, making it ideal for thin materials and intricate designs. EDM Die-Sinker employs a shaped electrode to erode cavities and intricate features directly into the workpiece, excelling in creating molds, dies, and components with deep recesses.

Overview of EDM Machining Technologies

EDM wire and EDM die-sinker are two primary EDM machining technologies used to produce intricate and precise metal components. EDM wire uses a continuously moving wire electrode to cut complex shapes with tight tolerances, ideal for thin sections and contours, while EDM die-sinker employs a shaped electrode submerged in dielectric fluid to erode cavities, perfect for detailed mold and die work. Your choice between these methods depends on the required geometry, surface finish, and machining speed for the application.

Key Differences Between Wire EDM and Die-Sinker EDM

Wire EDM uses a thin, continuous wire to cut complex shapes with high precision and minimal material waste, ideal for intricate metal parts; Die-Sinker EDM employs a shaped electrode to create cavities and detailed 3D forms in harder materials. Wire EDM excels in cutting thin sections and producing tight tolerances, while Die-Sinker EDM is better suited for deep cavities, internal corners, and larger workpieces. Your choice depends on the part geometry, surface finish requirements, and production volume.

Applications: When to Use Wire EDM

Wire EDM is ideal for cutting intricate shapes and fine details in hard metals, making it perfect for applications requiring high precision in tool and die manufacturing. You should use Wire EDM when working on thin materials or creating complex contours that require minimal material distortion. In contrast, EDM die-sinker is better suited for cavity formation and deeper, three-dimensional profiles in tougher metals.

Applications: When to Use Die-Sinker EDM

EDM wire is ideal for cutting precise, intricate shapes in thin to medium-thickness conductive materials, commonly used in mold making and fine detail work. EDM die-sinker is preferable for creating complex cavities, deep cavities, or 3D shapes in thick materials, often applied in tool and die manufacturing or aerospace components. You should use die-sinker EDM when your project demands detailed, deep, or complex geometries that wire EDM cannot achieve.

Material Compatibility: Wire EDM vs Die-Sinker EDM

Wire EDM excels at machining hard, electrically conductive materials such as tool steel, titanium, and hardened alloys with high precision. Die-sinker EDM is better suited for complex shapes and cavities in materials that may be less conductive or require intricate detailing, including carbides and refractory metals. Your choice depends on the specific material properties and the geometric complexity of the workpiece.

Accuracy and Surface Finish Comparison

EDM wire machines deliver high accuracy with tight tolerances often within +-0.002 mm, making them ideal for intricate contours and fine details. EDM die-sinker technology excels in achieving superior surface finish, frequently reaching Ra values as low as 0.1 um due to fine electrode control and controlled sparking. Wire EDM's precision suits complex 2D profiles, while die-sinker EDM provides enhanced surface quality for 3D cavities and molds.

Cost Considerations and Operational Efficiency

EDM wire offers lower initial setup costs and faster machining speeds, making it cost-effective for high-volume production and intricate external shapes. EDM die-sinker incurs higher tooling expenses and longer cycle times but excels in machining complex internal cavities with superior precision. Operational efficiency favors EDM wire for continuous cutting tasks, while die-sinker is preferred for detailed, multi-axis EDM applications requiring fine surface finishes.

Pros and Cons of Wire EDM vs Die-Sinker EDM

Wire EDM offers high precision for intricate, thin cuts with minimal material distortion, making it ideal for complex geometries and delicate parts. Die-sinker EDM excels in producing deep cavities and complex 3D shapes but generally has slower machining times and higher electrode maintenance costs. You should choose Wire EDM for fine, detailed work and Die-sinker EDM for deeper molds or parts requiring intricate surface contours.

Choosing the Right EDM Method for Your Project

EDM wire cutting excels in precision for intricate and thin parts, while EDM die-sinker is better suited for complex cavities and deep profiles. Your project's material thickness, geometry, and surface finish requirements determine the optimal EDM method. Selecting the right EDM technique ensures efficiency, accuracy, and cost-effectiveness in manufacturing.

EDM wire vs EDM die-sinker Infographic

libmatt.com

libmatt.com