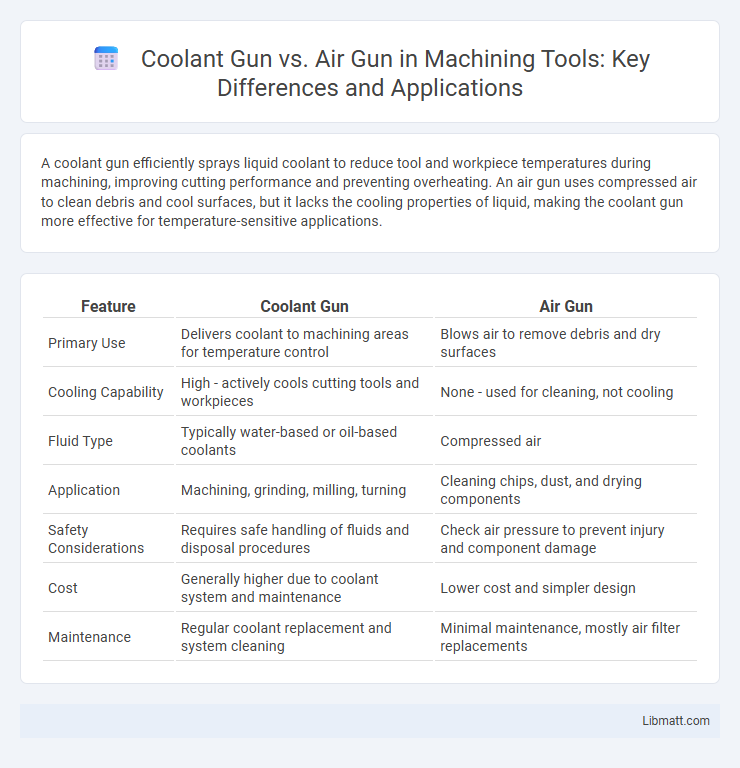

A coolant gun efficiently sprays liquid coolant to reduce tool and workpiece temperatures during machining, improving cutting performance and preventing overheating. An air gun uses compressed air to clean debris and cool surfaces, but it lacks the cooling properties of liquid, making the coolant gun more effective for temperature-sensitive applications.

Table of Comparison

| Feature | Coolant Gun | Air Gun |

|---|---|---|

| Primary Use | Delivers coolant to machining areas for temperature control | Blows air to remove debris and dry surfaces |

| Cooling Capability | High - actively cools cutting tools and workpieces | None - used for cleaning, not cooling |

| Fluid Type | Typically water-based or oil-based coolants | Compressed air |

| Application | Machining, grinding, milling, turning | Cleaning chips, dust, and drying components |

| Safety Considerations | Requires safe handling of fluids and disposal procedures | Check air pressure to prevent injury and component damage |

| Cost | Generally higher due to coolant system and maintenance | Lower cost and simpler design |

| Maintenance | Regular coolant replacement and system cleaning | Minimal maintenance, mostly air filter replacements |

Introduction to Coolant Gun and Air Gun

Coolant guns deliver pressurized coolant fluid to industrial machinery, enhancing heat dissipation and preventing overheating during high-speed operations. Air guns use compressed air to clean surfaces or remove debris, providing a dry and residue-free alternative for maintenance tasks. Your choice depends on specific needs like cooling efficiency or debris removal in manufacturing environments.

Functionality Overview: How They Work

A coolant gun sprays a controlled stream of liquid coolant to reduce the temperature of machinery or cutting tools by dissipating heat through direct contact, enhancing operational efficiency. An air gun uses compressed air to blow away debris, dust, or chips from surfaces and equipment, ensuring cleanliness without liquid residue. Both tools are essential in industrial maintenance but serve distinct purposes: cooling versus cleaning.

Application Areas in Industrial Settings

Coolant guns are essential for precision cooling and lubrication in machining operations, improving tool life and part quality in industries such as automotive manufacturing and metalworking. Air guns are widely used for cleaning, drying, and debris removal in assembly lines, electronics manufacturing, and maintenance tasks. Choosing the right tool depends on your specific application needs, ensuring optimal performance and productivity in your industrial environment.

Performance Comparison: Cooling Efficiency

Coolant guns deliver superior cooling efficiency by directly applying liquid coolant to hot surfaces, rapidly absorbing and dissipating heat during machining processes. Air guns, while effective for removing debris and drying parts, lack the thermal conductivity properties necessary for significant temperature reduction. Your choice between the two will impact machining quality, with coolant guns offering enhanced performance in temperature control and tool longevity.

Cost Analysis: Initial and Maintenance Expenses

Coolant guns generally have higher initial costs due to complex mechanisms designed for precise fluid delivery, while air guns are more affordable upfront with simpler construction. Maintenance expenses for coolant guns include frequent fluid refills and potential seal replacements, reflecting their reliance on liquid components; air guns typically incur lower maintenance costs centered around air compressor upkeep and filter changes. Your choice between these tools should consider not only the initial investment but also long-term maintenance to optimize cost efficiency in your application.

Safety Considerations and Workplace Impact

Coolant guns reduce airborne contaminants and minimize the risk of fire hazards by delivering a controlled flow of coolant, enhancing workplace safety compared to air guns that can disperse dust and debris in the air. Air guns often generate high-velocity streams that may cause eye injuries or respiratory problems without proper protective gear. Your choice between these tools should prioritize safety protocols and environmental impact to ensure a healthier and safer working environment.

Energy Consumption and Environmental Impact

Coolant guns consume significantly more energy than air guns due to the power needed for coolant circulation and pressure maintenance, leading to higher operational costs and environmental footprint. Air guns operate using compressed air, which, while energy-efficient, requires energy-intensive compressors, yet overall they typically produce fewer emissions and less coolant waste. You can reduce environmental impact by choosing an air gun for its lower energy consumption and minimal coolant discharge, aligning with sustainable industrial practices.

User Experience: Ease of Operation

Coolant guns offer users superior ease of operation with ergonomic designs that reduce hand fatigue during extended use, featuring intuitive trigger mechanisms for precise coolant flow control. Air guns typically require more manual effort and can cause discomfort over time due to their less ergonomic handles and inconsistent airflow management. The user experience of coolant guns is enhanced by adjustable pressure settings and lightweight materials, making them more comfortable and efficient for repetitive tasks.

Choosing the Right Tool: Key Decision Factors

Choosing between a coolant gun and an air gun depends on factors like the specific application, required cooling efficiency, and workspace safety. A coolant gun delivers precise fluid cooling for machining processes, enhancing tool life and surface finish, while an air gun provides high-velocity air for cleaning or drying tasks without moisture. Consider your cooling needs, environmental conditions, and equipment compatibility to select the most effective tool for your operations.

Conclusion: Which Tool Is Best for Your Needs?

Choosing between a coolant gun and an air gun depends on your specific application requirements. Coolant guns excel in precision cooling and lubrication for machining processes, enhancing tool life and workpiece quality, while air guns are ideal for quick drying, debris removal, and general cleaning tasks. Assessing your needs for temperature control, efficiency, and cleanliness will help you determine which tool best supports your productivity and maintenance goals.

Coolant gun vs air gun Infographic

libmatt.com

libmatt.com