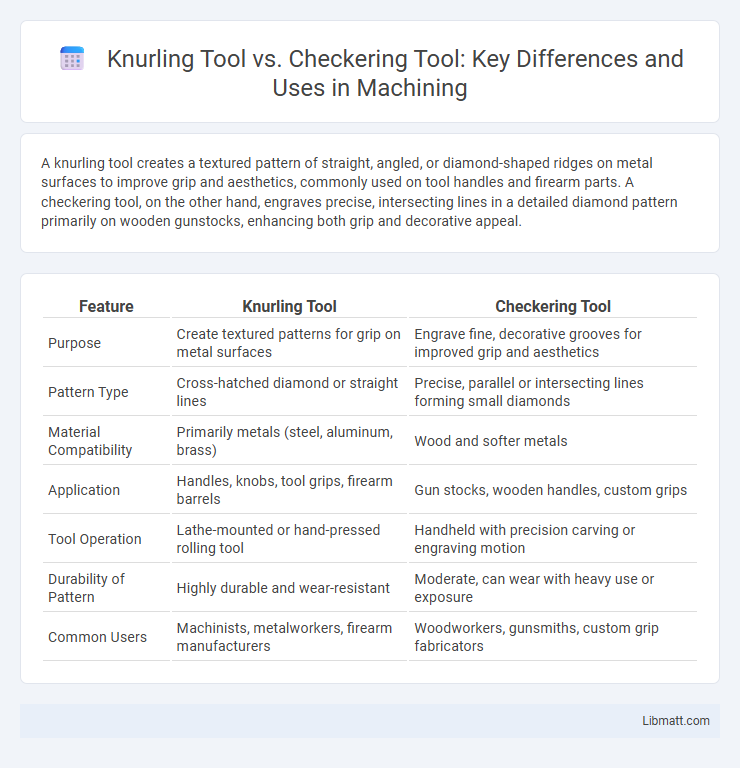

A knurling tool creates a textured pattern of straight, angled, or diamond-shaped ridges on metal surfaces to improve grip and aesthetics, commonly used on tool handles and firearm parts. A checkering tool, on the other hand, engraves precise, intersecting lines in a detailed diamond pattern primarily on wooden gunstocks, enhancing both grip and decorative appeal.

Table of Comparison

| Feature | Knurling Tool | Checkering Tool |

|---|---|---|

| Purpose | Create textured patterns for grip on metal surfaces | Engrave fine, decorative grooves for improved grip and aesthetics |

| Pattern Type | Cross-hatched diamond or straight lines | Precise, parallel or intersecting lines forming small diamonds |

| Material Compatibility | Primarily metals (steel, aluminum, brass) | Wood and softer metals |

| Application | Handles, knobs, tool grips, firearm barrels | Gun stocks, wooden handles, custom grips |

| Tool Operation | Lathe-mounted or hand-pressed rolling tool | Handheld with precision carving or engraving motion |

| Durability of Pattern | Highly durable and wear-resistant | Moderate, can wear with heavy use or exposure |

| Common Users | Machinists, metalworkers, firearm manufacturers | Woodworkers, gunsmiths, custom grip fabricators |

Introduction to Knurling and Checkering Tools

Knurling tools create textured patterns on metal surfaces by deforming material to produce precise, repetitive ridges that enhance grip and aesthetics. Checkering tools cut fine, intersecting grooves into wood or metal, commonly used on firearm grips for increased tactile control. Both tools improve handling but differ in technique, material compatibility, and pattern design.

What is a Knurling Tool?

A knurling tool is a machining accessory used to create a patterned texture on metal surfaces, providing enhanced grip and aesthetic appeal. It produces a series of straight, angled, or crossed lines by pressing hardened wheels or rollers against the workpiece, commonly used in handles, knobs, and tool grips. Unlike a checkering tool, which cuts precise, repetitive diamond-shaped patterns, knurling tools deform the material to form raised ridges.

What is a Checkering Tool?

A checkering tool is a precision instrument used to create fine, intersecting grooves on metal or wood surfaces, enhancing grip and aesthetic appeal. Unlike a knurling tool, which produces a raised pattern by pressing or rolling, a checkering tool cuts sharp, shallow lines forming diamond-shaped patterns. Your firearm or woodworking project benefits from a checkering tool by achieving detailed textures that improve handling and visual quality.

Key Differences Between Knurling and Checkering

Knurling tools create a series of straight, angled, or diamond-shaped ridges on metal surfaces to enhance grip and aesthetics, primarily used in machining processes. Checkering tools, by contrast, produce intricate, crisscrossed patterns typically found on firearm grips and wooden handles, providing both decorative appeal and improved tactile control. Your choice between knurling and checkering depends on the desired texture, application surface, and visual design requirements.

Applications of Knurling Tools

Knurling tools are primarily used to create textured patterns on cylindrical metal surfaces to enhance grip and aesthetic appeal, often found on tool handles, knobs, and firearm parts. These tools form a permanent, raised diamond or straight pattern through cold working, improving functionality in industrial and machining applications. Unlike checkering tools that cut precise grooves for similar grip enhancement, knurling tools emboss patterns rapidly and efficiently on softer metals.

Applications of Checkering Tools

Checkering tools are primarily used in woodworking and firearms to create intricate, crisscross patterns that enhance grip and aesthetic appeal. Unlike knurling tools, which produce uniform, rounded ridges primarily on metal surfaces, checkering tools allow for precise, decorative detailing on wood or metal handles. Your craftsmanship benefits from the added texture and elegance that checkering provides, improving both functionality and visual appeal in custom projects.

Material Compatibility: Knurling vs Checkering

Knurling tools excel in creating textured patterns on softer metals such as aluminum, brass, and mild steel, providing enhanced grip without significant material removal. Checkering tools are better suited for harder materials like hardwood and gunstock-grade walnut, where precise, diamond-shaped grooves improve tactile control. Each tool's effectiveness depends on the material's hardness and intended surface finish, requiring careful selection based on application demands.

Advantages & Limitations of Knurling

Knurling tools provide a quick and efficient method to create textured patterns on metal surfaces, enhancing grip and aesthetics without requiring intricate engraving skills. Their advantages include ease of use, speed, and the ability to produce consistent, durable patterns ideal for tools and handles, while limitations involve less design versatility and potential material deformation if not applied correctly. Your choice between knurling and checkering tools depends on the desired texture complexity, with knurling excelling in functional grip enhancement and checkering offering more detailed, decorative finishes.

Advantages & Limitations of Checkering

Checkering tools create intricate patterns that enhance grip and aesthetic appeal, offering precise and customizable designs compared to knurling tools. The main advantage of checkering is its ability to provide superior tactile feedback and visual detail on firearm stocks and knife handles. However, checkering requires advanced skill and more time to execute, making it less suitable for mass production and more vulnerable to wear in heavy-use environments.

How to Choose Between Knurling and Checkering Tools

Choosing between knurling and checkering tools depends largely on the texture and grip pattern you want to achieve on your workpiece. Knurling tools create a series of uniform, diamond-shaped or straight ridges ideal for enhancing grip on metal handles or knobs, while checkering tools produce finely cut, crisscross patterns favored for decorative and functional gunstocks or wooden grips. Your selection should consider the material, desired aesthetic, and functional grip characteristics to ensure optimal tool performance and product quality.

Knurling tool vs checkering tool Infographic

libmatt.com

libmatt.com