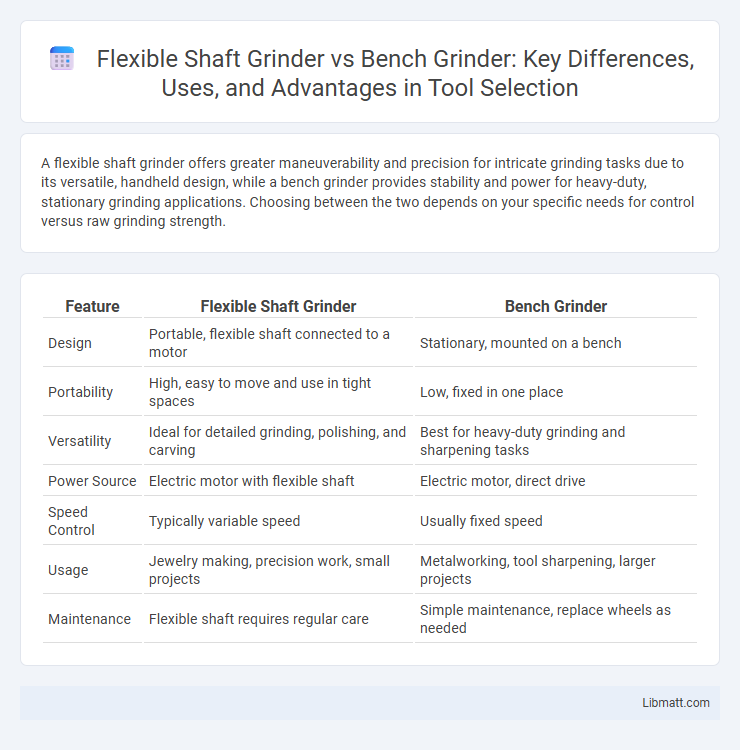

A flexible shaft grinder offers greater maneuverability and precision for intricate grinding tasks due to its versatile, handheld design, while a bench grinder provides stability and power for heavy-duty, stationary grinding applications. Choosing between the two depends on your specific needs for control versus raw grinding strength.

Table of Comparison

| Feature | Flexible Shaft Grinder | Bench Grinder |

|---|---|---|

| Design | Portable, flexible shaft connected to a motor | Stationary, mounted on a bench |

| Portability | High, easy to move and use in tight spaces | Low, fixed in one place |

| Versatility | Ideal for detailed grinding, polishing, and carving | Best for heavy-duty grinding and sharpening tasks |

| Power Source | Electric motor with flexible shaft | Electric motor, direct drive |

| Speed Control | Typically variable speed | Usually fixed speed |

| Usage | Jewelry making, precision work, small projects | Metalworking, tool sharpening, larger projects |

| Maintenance | Flexible shaft requires regular care | Simple maintenance, replace wheels as needed |

Introduction to Grinding Tools

Flexible shaft grinders offer precision and maneuverability for detailed grinding tasks, featuring a long, flexible shaft that allows access to tight or complex areas. Bench grinders provide stability and power for heavy-duty grinding work, ideal for sharpening, shaping, and removing material from metal parts on a fixed base. Choosing between these tools depends on the specific requirements of the job, such as precision versus power and accessibility versus robustness.

What is a Flexible Shaft Grinder?

A flexible shaft grinder is a power tool consisting of a motor connected to a flexible shaft, allowing the user to maneuver a small, handheld grinding head for precision work in tight or intricate spaces. Unlike bench grinders that have fixed wheels mounted on a stationary base, flexible shaft grinders offer enhanced control and versatility, making them ideal for detailed grinding, polishing, and engraving tasks. This tool is commonly used in jewelry making, automotive repair, and metalworking industries where fine, accurate grinding is essential.

What is a Bench Grinder?

A bench grinder is a stationary grinding machine mounted on a workbench, equipped with two abrasive wheels designed for sharpening, shaping, and polishing metal tools and components. It offers high stability and precision, making it ideal for heavy-duty grinding tasks and consistent performance in workshops. Unlike a flexible shaft grinder, which features a motor connected to a flexible shaft for intricate detail work, the bench grinder excels in robust material removal and surface preparation.

Key Differences Between Flexible Shaft and Bench Grinders

Flexible shaft grinders offer enhanced maneuverability with a long, flexible shaft allowing precision work in tight spaces, while bench grinders provide a stable, stationary platform ideal for heavy-duty grinding tasks. The flexible shaft grinder is best suited for detailed shaping and polishing, whereas bench grinders excel in coarse grinding and sharpening larger tools. Power and speed settings vary, with bench grinders typically featuring higher horsepower and fixed speed, compared to the versatile, adjustable speed control of flexible shaft grinders.

Performance and Versatility Comparison

Flexible shaft grinders offer superior precision and maneuverability, making them ideal for detailed work and intricate grinding tasks. Bench grinders provide robust performance with higher power and stability, suitable for heavy-duty sharpening and shaping jobs. Your choice depends on whether you prioritize detailed versatility or consistent heavy performance.

Ease of Use and Ergonomics

Flexible shaft grinders provide superior ease of use by offering enhanced maneuverability and precision through a lightweight, handheld design that reduces user fatigue during detailed work. Bench grinders, while sturdy, often require repositioning the workpiece and can cause strain due to their fixed position and heavier weight. Ergonomically, flexible shaft grinders allow for better wrist and hand positioning, minimizing repetitive stress injuries compared to the static posture needed when using bench grinders.

Suitable Applications for Each Grinder

Flexible shaft grinders excel in precision tasks such as jewelry making, detailed carving, and intricate metalwork, offering superior control in tight spaces. Bench grinders are ideal for heavy-duty applications like sharpening tools, shaping metal, and removing rust, providing greater power and stability for larger projects. Your choice depends on whether you prioritize fine detail work or robust material removal.

Safety Considerations

Flexible shaft grinders offer enhanced safety by keeping the motor separate, reducing vibration and heat near your hands, which minimizes fatigue and risk of injury. Bench grinders provide a stable, stationary setup but require careful use of guards and eye protection to prevent debris-related accidents. Your choice should prioritize proper handling and maintenance practices to ensure a safe grinding experience with either tool.

Cost and Maintenance Factors

Flexible shaft grinders generally have higher initial costs compared to bench grinders due to their specialized attachments and design, but they offer greater versatility for detailed work. Maintenance of flexible shaft grinders often involves more frequent lubrication, cable replacement, and careful handling to prevent wear, whereas bench grinders require simpler upkeep, mainly focusing on wheel dressing and motor checks. Over time, bench grinders tend to be more cost-effective for heavy-duty grinding, while flexible shaft grinders may incur additional expenses due to their precision components and maintenance needs.

Choosing the Right Grinder for Your Needs

Flexible shaft grinders provide enhanced precision and maneuverability, making them ideal for detailed work and intricate projects. Bench grinders deliver robust power and stability, suited for heavy-duty grinding, sharpening, and shaping tasks. Assess your specific grinding requirements and workspace constraints to determine whether the flexibility of a flexible shaft grinder or the durability of a bench grinder best fits your needs.

Flexible shaft grinder vs bench grinder Infographic

libmatt.com

libmatt.com