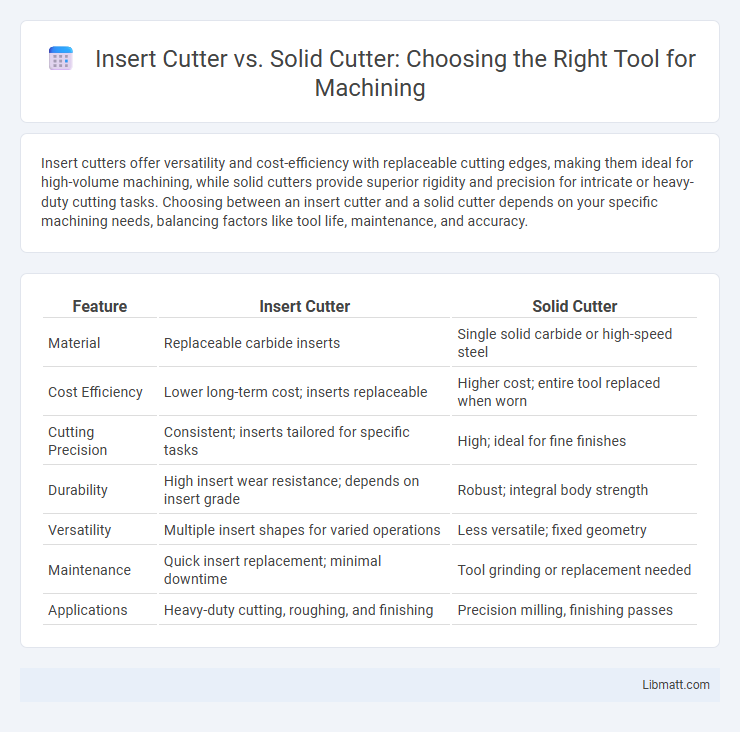

Insert cutters offer versatility and cost-efficiency with replaceable cutting edges, making them ideal for high-volume machining, while solid cutters provide superior rigidity and precision for intricate or heavy-duty cutting tasks. Choosing between an insert cutter and a solid cutter depends on your specific machining needs, balancing factors like tool life, maintenance, and accuracy.

Table of Comparison

| Feature | Insert Cutter | Solid Cutter |

|---|---|---|

| Material | Replaceable carbide inserts | Single solid carbide or high-speed steel |

| Cost Efficiency | Lower long-term cost; inserts replaceable | Higher cost; entire tool replaced when worn |

| Cutting Precision | Consistent; inserts tailored for specific tasks | High; ideal for fine finishes |

| Durability | High insert wear resistance; depends on insert grade | Robust; integral body strength |

| Versatility | Multiple insert shapes for varied operations | Less versatile; fixed geometry |

| Maintenance | Quick insert replacement; minimal downtime | Tool grinding or replacement needed |

| Applications | Heavy-duty cutting, roughing, and finishing | Precision milling, finishing passes |

Introduction to Insert Cutters and Solid Cutters

Insert cutters utilize replaceable cutting edges made from materials like carbide or ceramic, enabling quick tool changes and extended tool life in machining operations. Solid cutters consist of a single piece of cutting material, often high-speed steel or carbide, offering high rigidity and precise cutting for applications requiring superior surface finish and dimensional accuracy. Both cutter types serve distinct industrial applications, with insert cutters favored for versatility and economic efficiency, while solid cutters excel in high-precision tasks.

Key Differences Between Insert and Solid Cutters

Insert cutters feature replaceable cutting tips made of carbide or ceramic, enabling cost-effective maintenance and high wear resistance. Solid cutters consist of a single-piece tool, typically made from high-speed steel or solid carbide, offering greater rigidity and precision for heavy-duty machining. Insert cutters are versatile for varied applications due to interchangeable inserts, while solid cutters provide enhanced stability and surface finish in continuous cutting operations.

Advantages of Insert Cutters

Insert cutters offer several advantages, including easy and cost-effective replacement of cutting edges without changing the entire tool, which significantly reduces downtime and tooling costs. Their modular design enables consistent performance and improved precision, as you can quickly swap inserts to maintain optimal cutting conditions. You benefit from greater flexibility in cutting applications and extended tool life by selecting inserts designed for specific materials and operations.

Benefits of Solid Cutters

Solid cutters offer superior rigidity and precision compared to insert cutters, leading to enhanced machining accuracy and surface finish quality. Their one-piece construction reduces vibration and deflection, improving tool life and enabling efficient high-speed machining of tough materials. Maintenance is simplified since solid cutters do not require indexable inserts, lowering operational costs in long-term applications.

Applications: When to Use Insert Cutters

Insert cutters are ideal for high-volume machining of hard materials where tool life and quick insert changes increase productivity. Solid cutters suit precision work and complex shapes requiring sharp cutting edges and rigid tool construction. Your choice depends on whether ease of maintenance or detailed accuracy is the priority in your manufacturing process.

Applications: When to Use Solid Cutters

Solid cutters excel in applications requiring heavy-duty cutting, such as machining hardened steels or high-temperature alloys, where maximum tool strength and rigidity are essential. They are preferred for finishing operations needing superior surface finish and tight tolerance control due to their precise geometry and minimal vibration. Solid cutters are also optimal in interrupted cuts and roughing processes where tool toughness and impact resistance are critical for performance.

Cost Comparison: Insert Cutter vs Solid Cutter

Insert cutters generally offer lower long-term costs due to their replaceable cutting edges, minimizing the need for full tool replacement. Solid cutters, while initially more expensive, provide durability and precision without the recurring expense of inserts. Your choice should consider both upfront investment and maintenance expenses for optimized cost efficiency.

Tool Life and Maintenance Considerations

Insert cutters offer longer tool life due to replaceable cutting edges, reducing downtime and maintenance costs compared to solid cutters that require full tool replacement when worn. Solid cutters provide greater rigidity and precision but demand more frequent sharpening and higher maintenance effort. Selecting between the two depends on your machining requirements, balancing durability with ease of maintenance.

Performance and Precision Factors

Insert cutters offer enhanced performance by allowing quick replacement of worn cutting edges without changing the entire tool, maintaining consistent precision throughout machining. Solid cutters provide superior rigidity and vibration resistance, leading to higher accuracy in fine finishing tasks. Your choice between insert and solid cutters depends on the balance of tool life, maintenance ease, and the specific precision requirements of your application.

Selecting the Right Cutter for Your Machining Needs

Selecting the right cutter involves evaluating factors such as material hardness, machining precision, and cost-efficiency. Insert cutters offer versatility and easy replacement for high-volume production, making them ideal for tough materials and continuous operation. Solid cutters provide superior rigidity and finish quality in precision machining but may require more frequent regrinding and higher initial investment.

Insert cutter vs solid cutter Infographic

libmatt.com

libmatt.com