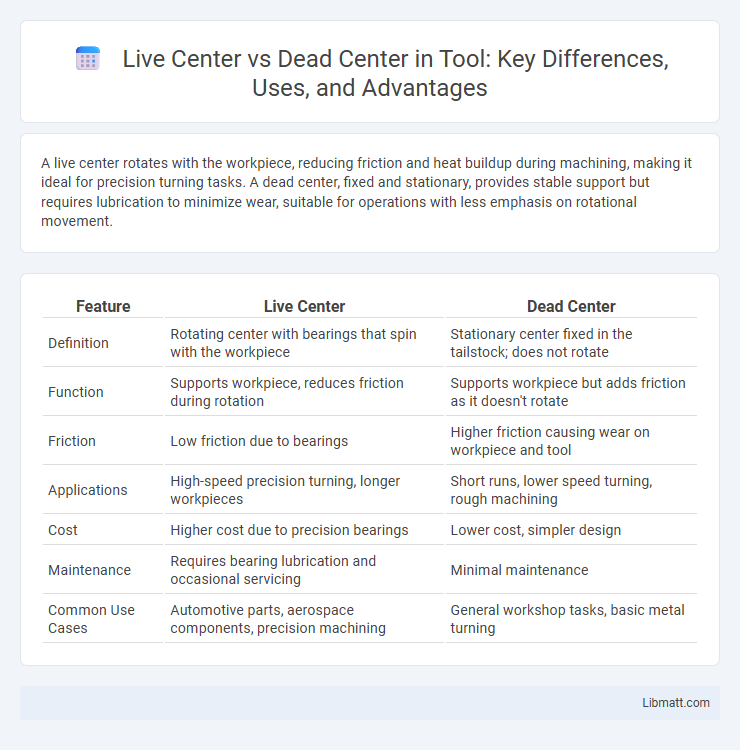

A live center rotates with the workpiece, reducing friction and heat buildup during machining, making it ideal for precision turning tasks. A dead center, fixed and stationary, provides stable support but requires lubrication to minimize wear, suitable for operations with less emphasis on rotational movement.

Table of Comparison

| Feature | Live Center | Dead Center |

|---|---|---|

| Definition | Rotating center with bearings that spin with the workpiece | Stationary center fixed in the tailstock; does not rotate |

| Function | Supports workpiece, reduces friction during rotation | Supports workpiece but adds friction as it doesn't rotate |

| Friction | Low friction due to bearings | Higher friction causing wear on workpiece and tool |

| Applications | High-speed precision turning, longer workpieces | Short runs, lower speed turning, rough machining |

| Cost | Higher cost due to precision bearings | Lower cost, simpler design |

| Maintenance | Requires bearing lubrication and occasional servicing | Minimal maintenance |

| Common Use Cases | Automotive parts, aerospace components, precision machining | General workshop tasks, basic metal turning |

Introduction to Live Centers and Dead Centers

Live centers and dead centers are essential tools in machining for supporting a workpiece on a lathe. A live center features a bearing that allows the center to rotate with the workpiece, reducing friction and heat buildup during high-speed operations. Dead centers, in contrast, remain stationary, transferring rotational force directly through the workpiece and are typically used for lower-speed or rough machining tasks.

What is a Live Center?

A live center is a rotating lathe tool with bearings that allow the center spindle to spin independently of the workpiece, reducing friction and heat buildup during machining. It provides precise support for the workpiece, enhancing stability and accuracy in turning operations. Unlike a dead center, which remains stationary and requires lubrication, a live center's self-contained bearings minimize wear and improve tool life.

What is a Dead Center?

A dead center refers to the precise axis point on a lathe that remains stationary and does not rotate, used primarily to support a workpiece's end during machining. It allows for secure positioning but can cause friction and heat buildup, requiring lubrication to prevent damage. Understanding the difference between dead center and live center helps optimize your machining efficiency by choosing the appropriate center based on rotational and support needs.

Key Differences Between Live Center and Dead Center

Live centers rotate with the workpiece, providing continuous support and reducing friction during machining, while dead centers remain stationary and require lubrication to minimize wear. Live centers typically feature bearings that enhance precision and prolong tool life, making them ideal for high-speed operations. Your choice between these centers affects machining accuracy, surface finish, and overall tool longevity.

Main Applications of Live Centers

Live centers are primarily used in lathe operations to support the workpiece's end while it rotates, ensuring high precision and stability during turning, drilling, and grinding tasks. Their main applications include machining long, slender workpieces that require continuous rotation without excessive heat buildup or friction, improving surface finish and tool life. You will find live centers essential for maximizing efficiency in metalworking, especially when maintaining concentricity and minimizing runout in CNC and manual lathes.

Main Applications of Dead Centers

Dead centers are primarily used in lathe operations where the workpiece requires stability without rotation of the center itself, making them ideal for supporting heavy or long workpieces during turning, grinding, or drilling. Their robust, non-rotating design prevents heat buildup and minimizes wear on the center, enhancing accuracy and surface finish in machining processes. Common applications include rough turning, facing operations, and situations demanding high rigidity and precise axial alignment.

Advantages of Using Live Centers

Live centers reduce friction and heat generation during high-speed machining by rotating with the workpiece, improving tool life and surface finish. They provide more precise support, minimizing workpiece deflection and enhancing accuracy in turning operations. The incorporation of bearings in live centers allows for smoother operation and reduced wear compared to dead centers, making them ideal for extended production runs.

Advantages of Using Dead Centers

Dead centers provide superior accuracy and stability when supporting workpieces during machining processes, as they do not rotate with the workpiece, minimizing friction and wear. Their fixed nature ensures consistent alignment and reduces the risk of deflection, enhancing precision for turning and grinding operations. Using dead centers in your setup improves tool life and surface finish quality by maintaining a rigid support point throughout the machining.

Factors to Consider When Choosing Between Live and Dead Centers

When choosing between live and dead centers, consider factors such as rotational speed, tool life, and the type of machining operation. Live centers are preferred for high-speed applications and delicate workpieces due to their bearing-supported rotation, which reduces friction and heat buildup. Dead centers are suitable for heavy-duty turning and rough cuts where tool rigidity and simplicity enhance workpiece stability.

Conclusion: Live Center vs Dead Center – Which to Choose?

Choosing between a live center and a dead center depends on your machining needs and precision requirements. A live center rotates with the workpiece, reducing friction and heat, making it ideal for high-speed turning and delicate materials. Your decision should consider factors like cutting speed, workpiece type, and longevity of the center in demanding operations.

Live center vs dead center Infographic

libmatt.com

libmatt.com