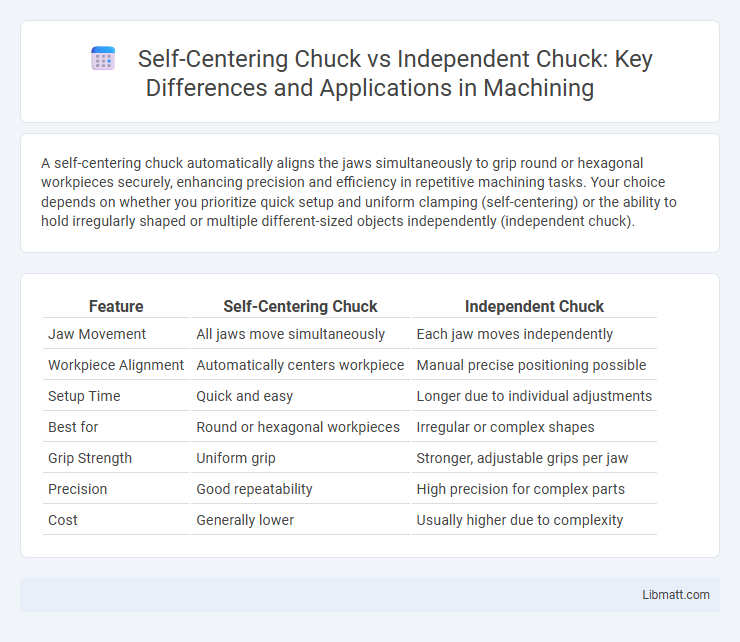

A self-centering chuck automatically aligns the jaws simultaneously to grip round or hexagonal workpieces securely, enhancing precision and efficiency in repetitive machining tasks. Your choice depends on whether you prioritize quick setup and uniform clamping (self-centering) or the ability to hold irregularly shaped or multiple different-sized objects independently (independent chuck).

Table of Comparison

| Feature | Self-Centering Chuck | Independent Chuck |

|---|---|---|

| Jaw Movement | All jaws move simultaneously | Each jaw moves independently |

| Workpiece Alignment | Automatically centers workpiece | Manual precise positioning possible |

| Setup Time | Quick and easy | Longer due to individual adjustments |

| Best for | Round or hexagonal workpieces | Irregular or complex shapes |

| Grip Strength | Uniform grip | Stronger, adjustable grips per jaw |

| Precision | Good repeatability | High precision for complex parts |

| Cost | Generally lower | Usually higher due to complexity |

Introduction: Understanding Lathe Chucks

Self-centering chucks, commonly used in lathe operations, feature jaws that move simultaneously to clamp a workpiece centrally and ensure consistent concentricity, ideal for round or hexagonal objects. Independent chucks allow each jaw to adjust separately, providing greater flexibility to grip irregular or complex shapes securely. The choice between these types depends on the precision requirements and the geometry of the workpiece during machining processes.

What Is a Self-Centering Chuck?

A self-centering chuck, also known as a scroll chuck, automatically positions its jaws equidistant from the center as they tighten, ensuring accurate and consistent clamping of round or hexagonal workpieces. Unlike an independent chuck where each jaw moves separately, the self-centering mechanism synchronizes jaw movement via a scroll plate, enhancing precision in machining applications. This type of chuck is widely used in lathes and machining centers for quick setup and reliable workholding.

What Is an Independent Chuck?

An independent chuck features jaws that move separately, allowing each jaw to be adjusted independently for gripping irregular or asymmetrical workpieces with precision. This design offers enhanced versatility in holding various shapes and sizes, making it ideal for complex machining tasks. Independent chucks provide superior control and customization compared to self-centering chucks, which move all jaws simultaneously.

Key Differences Between Self-Centering and Independent Chucks

Self-centering chucks feature jaws that move simultaneously to center a workpiece automatically, ensuring quick and consistent clamping for round or hexagonal objects. Independent chucks allow each jaw to be adjusted separately, providing greater precision and flexibility for irregularly shaped or off-center workpieces. The choice between these chuck types impacts machining accuracy, setup time, and application versatility in CNC and manual lathe operations.

Advantages of Self-Centering Chucks

Self-centering chucks offer uniform clamping pressure, ensuring precise alignment of cylindrical workpieces and reducing machining errors. Their simultaneous jaw movement makes them ideal for quick setup and repeatability in high-volume production. You benefit from improved efficiency and consistent accuracy when using self-centering chucks compared to independent chucks.

Advantages of Independent Chucks

Independent chucks offer precise, individual jaw adjustment, enabling accurate clamping of irregularly shaped or asymmetrical workpieces that self-centering chucks cannot securely hold. This flexibility enhances machining versatility and reduces setup time for complex parts, improving overall manufacturing efficiency. Their ability to maintain strong grip on varied geometries increases safety and minimizes workpiece slippage during high-torque operations.

Limitations of Self-Centering Chucks

Self-centering chucks offer rapid workpiece clamping but are limited by reduced grip strength on irregular or non-cylindrical shapes, leading to potential slippage and decreased machining accuracy. Their synchronized jaw movement restricts adjustment for uneven or tapered workpieces, making them less versatile compared to independent chucks, which allow individual jaw positioning for complex geometries. These limitations impact precision in tasks requiring customized grip configurations or high tolerance machining.

Limitations of Independent Chucks

Independent chucks face limitations in speed and clamping force uniformity compared to self-centering chucks, often resulting in uneven workpiece gripping. They require manual adjustment of each jaw individually, which increases setup time and the risk of misalignment, especially on complex or high-precision tasks. The lack of automatic jaw synchronization limits efficiency in rapid production environments where consistent centering and repeatability are critical.

Choosing the Right Chuck for Your Application

Selecting the right chuck depends on the precision and type of work required; self-centering chucks are ideal for holding round or hexagonal workpieces with uniform clamping force, ensuring consistent concentricity. Independent chucks offer superior flexibility by allowing each jaw to be adjusted separately, making them better suited for irregular or asymmetrical parts that require customized gripping. Understanding the workpiece geometry and machining goals is crucial for optimizing tool performance and achieving accurate results.

Conclusion: Self-Centering Chuck vs Independent Chuck

Self-centering chucks provide quick and uniform gripping for round or hexagonal workpieces, making them ideal for high-volume or repetitive machining tasks where consistency is crucial. Independent chucks offer precise adjustment of each jaw, delivering greater flexibility and accuracy for irregular or complex shapes, which benefits your custom or intricate projects. Choosing between them depends on whether your priority is speed and repeatability with self-centering chucks or tailored gripping and precision with independent chucks.

Self-centering chuck vs independent chuck Infographic

libmatt.com

libmatt.com