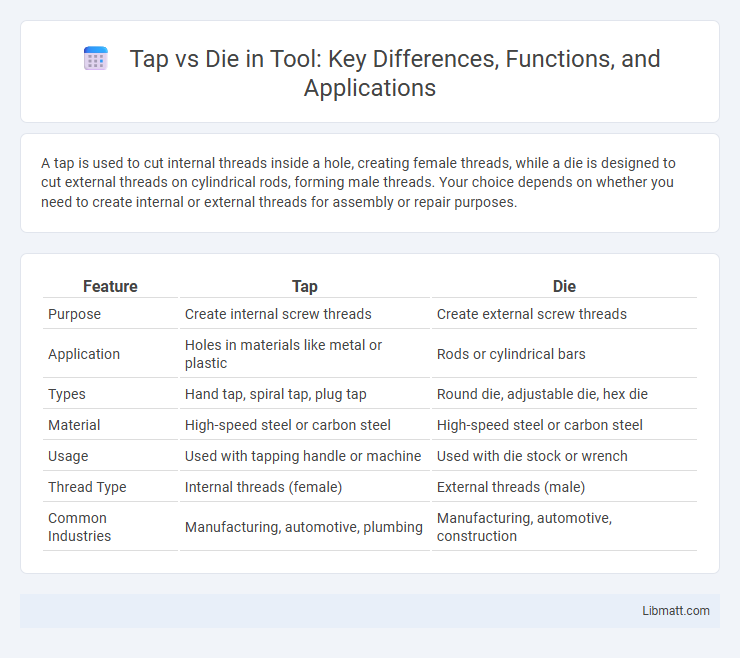

A tap is used to cut internal threads inside a hole, creating female threads, while a die is designed to cut external threads on cylindrical rods, forming male threads. Your choice depends on whether you need to create internal or external threads for assembly or repair purposes.

Table of Comparison

| Feature | Tap | Die |

|---|---|---|

| Purpose | Create internal screw threads | Create external screw threads |

| Application | Holes in materials like metal or plastic | Rods or cylindrical bars |

| Types | Hand tap, spiral tap, plug tap | Round die, adjustable die, hex die |

| Material | High-speed steel or carbon steel | High-speed steel or carbon steel |

| Usage | Used with tapping handle or machine | Used with die stock or wrench |

| Thread Type | Internal threads (female) | External threads (male) |

| Common Industries | Manufacturing, automotive, plumbing | Manufacturing, automotive, construction |

Introduction to Tap vs Die

Taps and dies are essential tools in metalworking used for creating screw threads. A tap cuts internal threads inside a hole, while a die shapes external threads on rods or bolts. Understanding the difference between tap vs die helps you choose the right tool for threading tasks, ensuring precision and durability in your projects.

Understanding Taps: Definition and Purpose

Taps are precision cutting tools designed to create internal threads within a pre-drilled hole, enabling the insertion of bolts or screws. These tools consist of spiral or straight flutes that efficiently remove material to form threads with specific pitch and diameter. Understanding taps is essential for ensuring accurate and durable threaded connections in manufacturing and repair processes.

Understanding Dies: Definition and Function

Dies are precision tools used in metalworking to cut external threads on cylindrical materials, enabling secure fastening with bolts or screws. Their function involves shaping the outer surface of rods or pipes by removing material to create matching threads for nuts. Understanding your die's size and thread pitch is crucial for achieving accurate threading and ensuring compatibility with corresponding fasteners.

Key Differences Between Taps and Dies

Taps and dies are essential tools used for cutting threads, with taps designed specifically to create internal threads inside holes, while dies are used to cut external threads on cylindrical rods. The primary difference lies in their application and shape: taps resemble small cylindrical drills with flutes allowing chip removal, whereas dies are round or hexagonal discs with cutting edges on the inside. Your choice between a tap or die depends on whether you need to thread holes or rods, making understanding their distinct functions critical for precise threading tasks.

Common Types of Taps

Common types of taps include taper taps, plug taps, and bottoming taps, each designed for specific threading tasks. Taper taps feature a gradual cutting edge for easy thread starting, plug taps are versatile with moderate taper for through holes, and bottoming taps have minimal taper for threading close to the bottom of blind holes. Selecting the appropriate tap type ensures optimal thread quality and tool longevity in metalworking applications.

Common Types of Dies

Common types of dies include round dies, adjustable dies, and hex dies, each designed for specific threading tasks. Round dies typically create external threads on cylindrical rods, while adjustable dies allow fine-tuning for precise thread fitting. Hex dies offer easy handling with standard wrenches, making them ideal for repairs and maintenance applications.

Applications: When to Use Tap and When to Use Die

Taps are used to create internal screw threads in holes, making them essential for tasks like threading holes in metal or plastic parts. Dies are designed to cut external threads on rods or bolts, perfect for repairing damaged threads or custom-sizing fasteners. You should use a tap when working on internal threading applications and a die when the project requires external threading on cylindrical materials.

Materials Compatible with Taps and Dies

Taps and dies are compatible with a variety of materials including steel, aluminum, brass, and plastic, allowing for versatile threading applications. High-speed steel taps and dies offer excellent durability and performance with harder metals like stainless steel, while carbon steel variants are ideal for softer materials such as aluminum and brass. Selecting the right tool for your project's material ensures precise thread cutting and extends the lifespan of your taps and dies.

Best Practices for Using Tap and Die Sets

Ensure to choose the correct tap and die size matching the thread specifications to avoid damaging the material. Always apply cutting oil to reduce friction and heat buildup, which extends tool life and improves thread quality. Use a tapping guide or die holder to maintain alignment and prevent cross-threading for precise, clean threads.

Maintenance and Safety Tips for Tap and Die Tools

Proper maintenance of tap and die tools includes regular cleaning to remove metal shavings and applying light machine oil to prevent rust and ensure smooth operation. Safety measures involve wearing protective gloves to avoid cuts from sharp edges and using appropriate cutting fluid to reduce friction and prevent tool breakage. Storing taps and dies in dedicated cases avoids damage and maintains their precision for accurate threading tasks.

Tap vs die Infographic

libmatt.com

libmatt.com