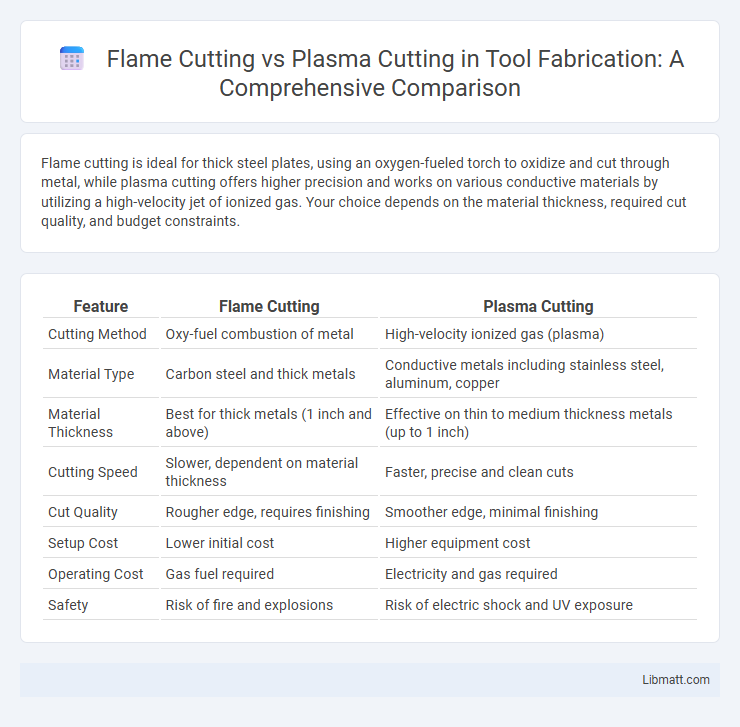

Flame cutting is ideal for thick steel plates, using an oxygen-fueled torch to oxidize and cut through metal, while plasma cutting offers higher precision and works on various conductive materials by utilizing a high-velocity jet of ionized gas. Your choice depends on the material thickness, required cut quality, and budget constraints.

Table of Comparison

| Feature | Flame Cutting | Plasma Cutting |

|---|---|---|

| Cutting Method | Oxy-fuel combustion of metal | High-velocity ionized gas (plasma) |

| Material Type | Carbon steel and thick metals | Conductive metals including stainless steel, aluminum, copper |

| Material Thickness | Best for thick metals (1 inch and above) | Effective on thin to medium thickness metals (up to 1 inch) |

| Cutting Speed | Slower, dependent on material thickness | Faster, precise and clean cuts |

| Cut Quality | Rougher edge, requires finishing | Smoother edge, minimal finishing |

| Setup Cost | Lower initial cost | Higher equipment cost |

| Operating Cost | Gas fuel required | Electricity and gas required |

| Safety | Risk of fire and explosions | Risk of electric shock and UV exposure |

Introduction to Flame Cutting and Plasma Cutting

Flame cutting utilizes a fuel gas, typically acetylene or propane, combined with oxygen to produce a high-temperature flame that oxidizes and melts metal, making it ideal for cutting thick steel plates. Plasma cutting employs an electrically conductive gas ionized into plasma, generating temperatures exceeding 20,000degC, enabling precise cuts on various metals including stainless steel, aluminum, and copper. Both methods serve distinct industrial applications, with flame cutting favored for heavy structural steel and plasma cutting preferred for detailed, high-speed metal fabrication.

How Flame Cutting Works

Flame cutting operates by using a high-temperature oxy-fuel flame to preheat the metal to its ignition temperature, then a stream of oxygen is directed at the heated area, causing the metal to oxidize and melt away. This process is most effective on ferrous metals like steel, as it relies on the material's ability to oxidize rapidly. The precise control of oxygen and fuel gases allows for clean, straight cuts on thick steel plates, making flame cutting ideal for heavy industrial applications.

How Plasma Cutting Works

Plasma cutting works by creating an electrical channel of superheated, electrically ionized gas--plasma--that melts the metal while a high-velocity jet blows the molten material away from the cut. This precise process uses a plasma torch powered by an electric arc, enabling rapid and accurate cutting of electrically conductive materials like steel, aluminum, and copper. Your choice of plasma cutting improves cutting speed and edge quality, especially for thinner metals compared to flame cutting.

Key Differences Between Flame and Plasma Cutting

Flame cutting uses a chemical reaction between oxygen and a fuel gas to melt and oxidize metal, making it ideal for cutting thick steel plates, while plasma cutting employs an ionized gas to conduct electricity, allowing precise cuts on a variety of conductive metals including stainless steel and aluminum. You will find flame cutting more suitable for heavy-duty, slower cuts on thicker materials, whereas plasma cutting offers faster, cleaner cuts with greater accuracy on thinner metals. The temperature of plasma cutting reaches up to 30,000degF, far exceeding the roughly 6,000degF flame cutting torch, which results in significant differences in cutting speed, edge quality, and material versatility.

Material Compatibility: Flame vs Plasma Cutting

Flame cutting excels at cutting thick, carbon steel and ferrous metals due to its use of an oxygen-fueled torch creating an exothermic reaction, making it less effective on non-ferrous or thin materials. Plasma cutting is highly versatile, capable of cleanly cutting a wide range of conductive metals including stainless steel, aluminum, and copper with precision, especially for thinner gauges. Your choice depends on the specific material type and thickness, as plasma cutting offers greater compatibility with diverse metals while flame cutting remains efficient for heavy-duty steel.

Cutting Speed Comparison

Flame cutting typically offers slower cutting speeds compared to plasma cutting, particularly on thinner metals where plasma cutting can operate up to five times faster. Plasma cutting excels in cutting speed due to its high-temperature ionized gas jet, enabling rapid and precise cuts on conductive materials such as steel, aluminum, and stainless steel. For thicker metals, flame cutting may become more competitive in speed, but plasma cutting generally remains the faster option for a wide range of material thicknesses.

Precision and Edge Quality

Plasma cutting offers higher precision and superior edge quality compared to flame cutting due to its concentrated plasma jet that produces cleaner, more accurate cuts with minimal heat distortion. Flame cutting tends to leave rougher edges and requires more post-processing because it uses an oxidizing flame that generates more slag and wider kerfs. Your choice between the two should consider the desired edge finish and tolerance levels, with plasma cutting excelling in applications demanding finer detail and smoother edges.

Cost and Equipment Considerations

Flame cutting requires lower-cost equipment and consumables compared to plasma cutting, making it more economical for heavy steel and thicker materials. Plasma cutting equipment involves higher initial investment and maintenance costs but offers increased precision and faster cutting speeds, suitable for thinner metals and detailed work. Choosing between flame and plasma cutting depends on project budget, material thickness, and required cut quality.

Safety and Operational Factors

Flame cutting involves open flames and combustible gases, requiring strict adherence to safety protocols to prevent fires and explosions, while plasma cutting uses electrically charged gas, posing risks of electric shock and UV radiation exposure that demand specialized protective gear. Operationally, flame cutting is slower and less precise, suitable for thicker steel but generating more slag, whereas plasma cutting offers faster speeds and cleaner cuts on a variety of metals with enhanced control for intricate designs. Both methods necessitate proper ventilation systems to manage toxic fumes and ensure operator safety during prolonged use.

Choosing the Right Cutting Method for Your Needs

Flame cutting excels in thickness versatility and cost-effectiveness for cutting steel up to 6 inches, while plasma cutting offers superior speed and precision for thin to medium metals, including stainless steel and aluminum. Selecting the right method depends on material type, thickness, required cut quality, and budget constraints. Plasma cutting suits detailed work and automation, whereas flame cutting is ideal for heavy-duty or large-scale steel fabrication projects.

Flame cutting vs plasma cutting Infographic

libmatt.com

libmatt.com