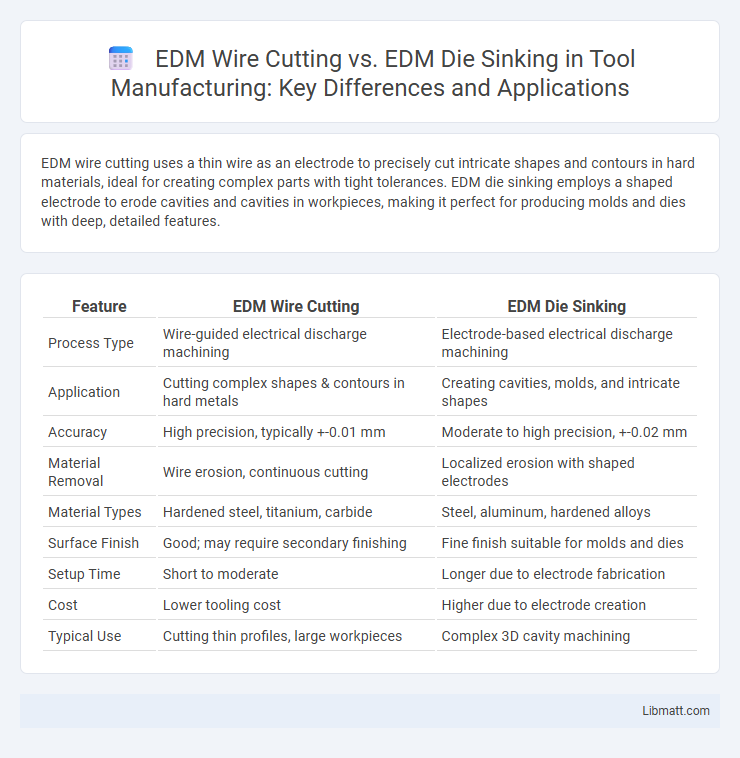

EDM wire cutting uses a thin wire as an electrode to precisely cut intricate shapes and contours in hard materials, ideal for creating complex parts with tight tolerances. EDM die sinking employs a shaped electrode to erode cavities and cavities in workpieces, making it perfect for producing molds and dies with deep, detailed features.

Table of Comparison

| Feature | EDM Wire Cutting | EDM Die Sinking |

|---|---|---|

| Process Type | Wire-guided electrical discharge machining | Electrode-based electrical discharge machining |

| Application | Cutting complex shapes & contours in hard metals | Creating cavities, molds, and intricate shapes |

| Accuracy | High precision, typically +-0.01 mm | Moderate to high precision, +-0.02 mm |

| Material Removal | Wire erosion, continuous cutting | Localized erosion with shaped electrodes |

| Material Types | Hardened steel, titanium, carbide | Steel, aluminum, hardened alloys |

| Surface Finish | Good; may require secondary finishing | Fine finish suitable for molds and dies |

| Setup Time | Short to moderate | Longer due to electrode fabrication |

| Cost | Lower tooling cost | Higher due to electrode creation |

| Typical Use | Cutting thin profiles, large workpieces | Complex 3D cavity machining |

Introduction to EDM Wire Cutting vs EDM Die Sinking

EDM Wire Cutting utilizes a thin wire as an electrode to produce intricate cuts with high precision, ideal for creating complex shapes and fine details in hard metals. EDM Die Sinking employs a shaped electrode to erode material from a workpiece, commonly used for making molds and dies with deep cavities and intricate surface textures. Both processes leverage electrical discharges to machine hard materials, but wire cutting excels in cutting profiles while die sinking is preferred for shaping and cavity creation.

How EDM Wire Cutting Works

EDM wire cutting uses a continuously moving thin wire as an electrode to erode material through rapid electrical discharges, producing precise cuts in hard metals. This process relies on a controlled spark gap between the wire and workpiece, where dielectric fluid flushes away molten material and debris, ensuring accuracy and minimal thermal distortion. Wire EDM excels in creating intricate shapes with tight tolerances in tool and mold making industries.

How EDM Die Sinking Operates

EDM die sinking operates by submerging a shaped electrode into a workpiece submerged in dielectric fluid, where controlled electrical discharges erode the metal to form precise cavities. The electrode shape directly determines the cavity's geometry, making this method ideal for complex molds and dies. High precision and surface finish result from the repetitive spark erosion process, allowing fine detail and accuracy in manufacturing.

Key Differences Between EDM Wire Cutting and Die Sinking

EDM wire cutting uses a thin, electrically charged wire to precisely slice through conductive materials, ideal for creating intricate shapes and fine details with minimal material waste. EDM die sinking employs a shaped electrode to erode material in a submerged tank, suitable for producing complex cavities and molds with high accuracy and fine surface finishes. You should choose wire cutting for detailed external cuts and die sinking when crafting detailed internal features or cavity shapes.

Material Compatibility Comparison

EDM wire cutting excels in processing thin, conductive materials such as hardened steel, titanium, and alloys with high precision, making it ideal for intricate shapes and fine details. EDM die sinking handles tougher, thicker materials like tool steels and carbides, allowing for deeper cavities and complex 3D forms with excellent surface finish. Choosing between EDM wire cutting and EDM die sinking depends on your specific material type and the desired geometric complexity for optimal results.

Precision and Surface Finish Considerations

EDM wire cutting offers superior precision for creating intricate shapes with tight tolerances, making it ideal for thin materials and complex contours. In contrast, EDM die sinking provides excellent surface finish quality on three-dimensional cavities and is preferred for detailed mold and die work. Understanding your specific requirements for accuracy and surface finish will help determine the best EDM process for your manufacturing needs.

Typical Applications for Each EDM Method

EDM wire cutting is ideal for producing intricate, sharp-edged parts such as punches, dies, and wire forms where precision and minimal material distortion are essential. EDM die sinking excels in creating complex cavities, molds, and detailed components requiring three-dimensional shapes with high surface finishes. Your manufacturing process can benefit from selecting wire EDM for linear or simple shapes and die sinking EDM for intricate, contoured designs.

Cost and Efficiency Analysis

EDM wire cutting generally offers lower operational costs and higher efficiency for producing complex, precise external shapes, optimizing material usage and minimizing post-processing expenses. EDM die sinking, while typically more expensive due to slower machining speeds and electrode wear, excels in creating intricate cavities and internal features with superior surface finishes, justifying higher costs in tool and mold manufacturing environments. Evaluating cost-efficiency between EDM wire cutting and die sinking depends on part geometry complexity, production volume, and required tolerances.

Advantages and Limitations of Both Techniques

EDM wire cutting offers precise, intricate cuts suitable for complex shapes and fine details with minimal material waste, making it ideal for thin or delicate workpieces, but it is limited by slower cutting speeds and a restriction to conductive materials. EDM die sinking provides deeper cavity machining with excellent surface finishes and can handle harder materials, yet it involves longer setup times and higher electrode costs, which may impact efficiency in high-volume production. Both techniques complement each other by balancing precision and depth capabilities, but selection depends on part geometry, material, and production scale.

Choosing the Right EDM Method for Your Project

EDM wire cutting offers precision in creating complex profiles and thin cuts ideal for intricate components, while EDM die sinking excels in producing detailed cavity shapes with smooth finishes on hard materials. Your project requirements for accuracy, material thickness, and geometric complexity determine the optimal EDM method. Evaluating factors like speed, surface quality, and electrode fabrication helps ensure you select the best EDM process for efficient machining results.

EDM wire cutting vs EDM die sinking Infographic

libmatt.com

libmatt.com