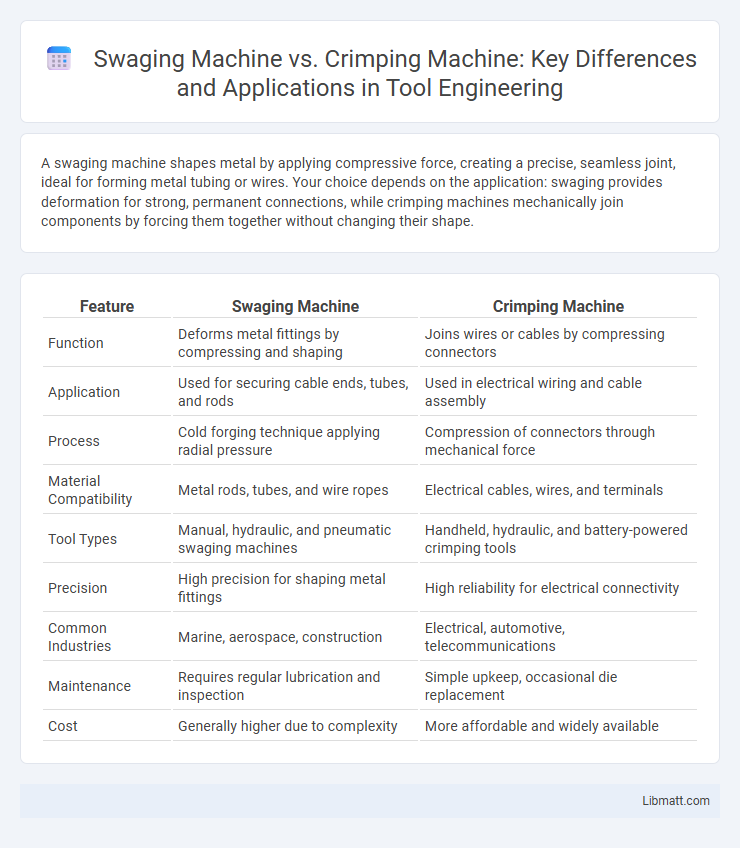

A swaging machine shapes metal by applying compressive force, creating a precise, seamless joint, ideal for forming metal tubing or wires. Your choice depends on the application: swaging provides deformation for strong, permanent connections, while crimping machines mechanically join components by forcing them together without changing their shape.

Table of Comparison

| Feature | Swaging Machine | Crimping Machine |

|---|---|---|

| Function | Deforms metal fittings by compressing and shaping | Joins wires or cables by compressing connectors |

| Application | Used for securing cable ends, tubes, and rods | Used in electrical wiring and cable assembly |

| Process | Cold forging technique applying radial pressure | Compression of connectors through mechanical force |

| Material Compatibility | Metal rods, tubes, and wire ropes | Electrical cables, wires, and terminals |

| Tool Types | Manual, hydraulic, and pneumatic swaging machines | Handheld, hydraulic, and battery-powered crimping tools |

| Precision | High precision for shaping metal fittings | High reliability for electrical connectivity |

| Common Industries | Marine, aerospace, construction | Electrical, automotive, telecommunications |

| Maintenance | Requires regular lubrication and inspection | Simple upkeep, occasional die replacement |

| Cost | Generally higher due to complexity | More affordable and widely available |

Introduction to Swaging and Crimping Machines

Swaging machines use a mechanical process to reshape metal by applying compressive forces, ideal for creating strong, permanent joints without heat. Crimping machines join materials by deforming one or both components to hold them together securely, commonly used in electrical and cable assemblies. Understanding the differences in how your swaging and crimping machines operate can help optimize your manufacturing or repair processes efficiently.

Fundamental Differences Between Swaging and Crimping

Swaging machines use a rotary or hammering action to deform a metal sleeve or fitting, creating a tight and permanent bond by compressing the material around a wire or cable. Crimping machines rely on a pressing tool that squeezes connectors onto wires through high pressure, ensuring mechanical and electrical continuity without altering the wire's shape significantly. The fundamental difference lies in swaging's deformation of the fitting's material for a seamless fit, while crimping mechanically secures connectors to wires with precise pressure application.

How Swaging Machines Work

Swaging machines operate by applying radial pressure through dies to deform metal tubes or wires, creating precise, permanent connections without heat or welding. This cold-forming process enhances the mechanical strength and electrical conductivity of the joint, making it ideal for cable assembly and aerospace applications. Your choice of a swaging machine ensures consistent, high-quality fittings with minimal material waste compared to crimping methods.

How Crimping Machines Operate

Crimping machines operate by compressing a metal sleeve or connector around a cable or wire using precise mechanical force, ensuring a secure and conductive connection. They utilize a die set tailored to the specific size and shape of the terminal, applying uniform pressure to deform the connector without damaging the wire strands. This method enhances electrical connectivity and mechanical stability, making crimping essential in automotive, aerospace, and electrical industries.

Applications of Swaging Machines

Swaging machines are primarily used in metal forming applications such as shaping, reducing, or tapering tubes, wires, and rods to achieve precise dimensions and enhanced mechanical properties. They are widely employed in aerospace, automotive, and manufacturing industries for producing seamless joints, fittings, and fasteners with high strength and durability. These machines are ideal for workpieces requiring uniform deformation without compromising material integrity, making them essential for creating custom components in heavy machinery and structural assemblies.

Applications of Crimping Machines

Crimping machines are widely used in electrical and telecommunications industries to securely join wires, cables, and connectors, ensuring optimal conductivity and mechanical strength. These machines are essential for creating reliable terminations in automotive wiring harnesses, aerospace components, and heavy machinery cables. Their precision and efficiency enable consistent quality in mass production environments, reducing the risk of connection failures and improving overall system performance.

Key Advantages of Swaging Machines

Swaging machines offer precise, high-strength metal forming with enhanced accuracy and repeatability compared to crimping machines, making them ideal for critical applications in aerospace and automotive industries. They provide superior joint integrity by applying radial compressive forces without deforming the entire workpiece, ensuring minimal material damage and improved durability. Swaging also enables seamless production of various sizes and shapes, enhancing versatility and reducing the risk of component failure under stress.

Benefits and Limitations of Crimping Machines

Crimping machines offer precise and reliable connections by compressing connectors onto cables, ensuring strong electrical and mechanical bonds ideal for automotive, aerospace, and electrical applications. They provide high efficiency and consistent results, but limitations include restricted compatibility with some connector types and potential deformation of delicate materials. Your choice of machine should consider the specific application requirements, balancing the need for speed and accuracy against material sensitivity.

Industry Suitability: Swaging vs Crimping

Swaging machines excel in industries requiring precise metal deformation for durable, high-strength fittings such as aerospace, automotive, and heavy machinery manufacturing. Crimping machines are better suited for electrical, telecommunications, and plumbing sectors where quick, reliable, and low-force fastening of wires and tubing is essential. Your choice depends on whether your application demands permanent metal reshaping or efficient fastening of softer materials.

Choosing the Right Machine for Your Needs

Selecting the right machine depends on the specific application and material requirements; swaging machines provide precise metal deformation ideal for producing uniform fittings, while crimping machines excel in creating strong, reliable connections for cables and wires. Swaging is preferred for high-strength, seamless joints without additional components, whereas crimping suits electrical, automotive, and telecommunications industries needing consistent electrical contact. Understanding the material thickness, production volume, and desired joint type ensures you choose a machine that maximizes efficiency and product quality.

Swaging machine vs crimping machine Infographic

libmatt.com

libmatt.com