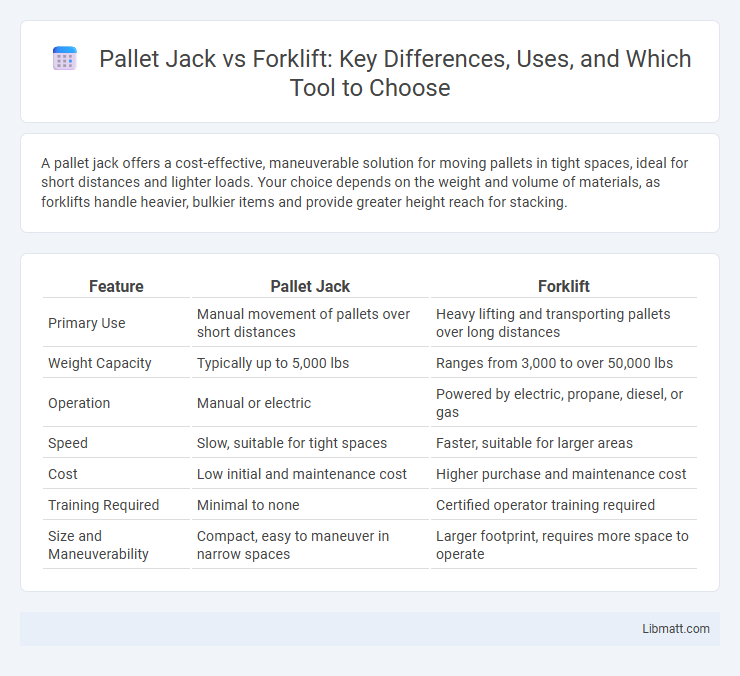

A pallet jack offers a cost-effective, maneuverable solution for moving pallets in tight spaces, ideal for short distances and lighter loads. Your choice depends on the weight and volume of materials, as forklifts handle heavier, bulkier items and provide greater height reach for stacking.

Table of Comparison

| Feature | Pallet Jack | Forklift |

|---|---|---|

| Primary Use | Manual movement of pallets over short distances | Heavy lifting and transporting pallets over long distances |

| Weight Capacity | Typically up to 5,000 lbs | Ranges from 3,000 to over 50,000 lbs |

| Operation | Manual or electric | Powered by electric, propane, diesel, or gas |

| Speed | Slow, suitable for tight spaces | Faster, suitable for larger areas |

| Cost | Low initial and maintenance cost | Higher purchase and maintenance cost |

| Training Required | Minimal to none | Certified operator training required |

| Size and Maneuverability | Compact, easy to maneuver in narrow spaces | Larger footprint, requires more space to operate |

Introduction to Pallet Jacks and Forklifts

Pallet jacks and forklifts are essential material handling equipment used in warehouses and factories to move heavy loads efficiently. Pallet jacks are manual or electric tools designed for lifting and sliding pallets over short distances, ideal for tight spaces and lighter loads. Forklifts, equipped with powerful engines and hydraulic lifting systems, handle heavier weights and higher stacking, making them suitable for large-scale industrial operations.

Key Differences Between Pallet Jacks and Forklifts

Pallet jacks and forklifts differ significantly in capacity, functionality, and operation; pallet jacks typically handle loads up to 5,500 pounds and are ideal for moving pallets short distances on smooth surfaces. Forklifts offer higher lifting capacities, often exceeding 20,000 pounds, and are equipped for stacking, loading, and transporting materials in various industrial environments. The operational complexity and cost also vary, with pallet jacks being manual or electric-powered and more affordable, while forklifts require trained operators and represent a larger investment in equipment and maintenance.

Load Capacity Comparison

Pallet jacks typically support load capacities ranging from 4,500 to 6,000 pounds, making them ideal for lighter warehouse tasks and short-distance material handling. Forklifts boast significantly higher load capacities, often between 5,000 and 20,000 pounds, suitable for heavy-duty lifting and stacking in industrial environments. Understanding your load requirements ensures you select the equipment that balances operational efficiency with safety standards for your specific material handling needs.

Maneuverability and Space Requirements

Pallet jacks offer superior maneuverability in tight spaces due to their compact design, making them ideal for narrow aisles and confined warehouse environments. Forklifts require significantly more space to operate and turn, limiting their use in cramped areas but providing greater lifting capacity for heavy loads. Your choice between the two should consider aisle width and operational space to optimize efficiency and safety in material handling.

Cost Analysis: Pallet Jack vs Forklift

Pallet jacks typically cost between $200 and $3,000, offering a cost-effective solution for light-duty material handling compared to forklifts, which range from $15,000 to $50,000 or more depending on capacity and features. Maintenance expenses for pallet jacks remain significantly lower, averaging around $200 annually, whereas forklift maintenance costs can exceed $3,000 per year due to complex hydraulics and engines. Operational costs, including fuel or electricity consumption, further differentiate forklifts as more expensive investments, making pallet jacks ideal for smaller warehouses and low-frequency lifting tasks.

Safety Considerations for Each Equipment

Pallet jacks offer enhanced maneuverability in tight spaces with lower risk of tip-overs but require careful operator training to avoid foot injuries and strain from manual pushing. Forklifts demand rigorous safety protocols due to higher load capacity and elevated center of gravity, increasing risks of rollovers and collisions, necessitating certified operators and regular equipment inspections. Both machines benefit from clear communication, proper load securing, and awareness of workplace conditions to minimize accidents and ensure safe material handling.

Maintenance and Durability

Pallet jacks require minimal maintenance due to their simple hydraulic systems and fewer moving parts, making them highly durable for light to moderate material handling tasks. Forklifts involve more complex engines and hydraulic components, necessitating regular maintenance such as fluid checks, battery upkeep, and tire replacement to ensure longevity. Your choice between a pallet jack and forklift depends on balancing the ease of upkeep with the durability needed for your specific workload.

Ideal Applications for Pallet Jacks

Pallet jacks are ideal for maneuvering pallets in tight spaces, such as retail stores, warehouses, and small storage areas, where forklift use would be impractical or unsafe. They excel in short-distance pallet moving and loading tasks, making them efficient for order picking, inventory restocking, and light-duty material handling. Your choice of a pallet jack ensures cost-effective, easy-to-operate equipment for tasks requiring manual control and limited lifting capacity.

Ideal Applications for Forklifts

Forklifts are ideal for heavy lifting and transporting large loads in warehouses, construction sites, and industrial settings where high stacking and maneuverability are required. They excel in handling pallets, bulky materials, and heavy equipment over uneven surfaces or long distances. Their versatility makes them essential for loading and unloading trucks, organizing inventory, and facilitating large-scale material movement efficiently.

Choosing the Right Equipment for Your Warehouse

Selecting the right equipment for your warehouse depends on load capacity, space constraints, and operational efficiency. Pallet jacks are ideal for moving lighter loads over short distances in tight spaces, while forklifts handle heavier materials and higher stacking needs with greater speed. Understanding your warehouse layout and workload ensures you choose equipment that maximizes productivity and safety.

Pallet jack vs forklift Infographic

libmatt.com

libmatt.com