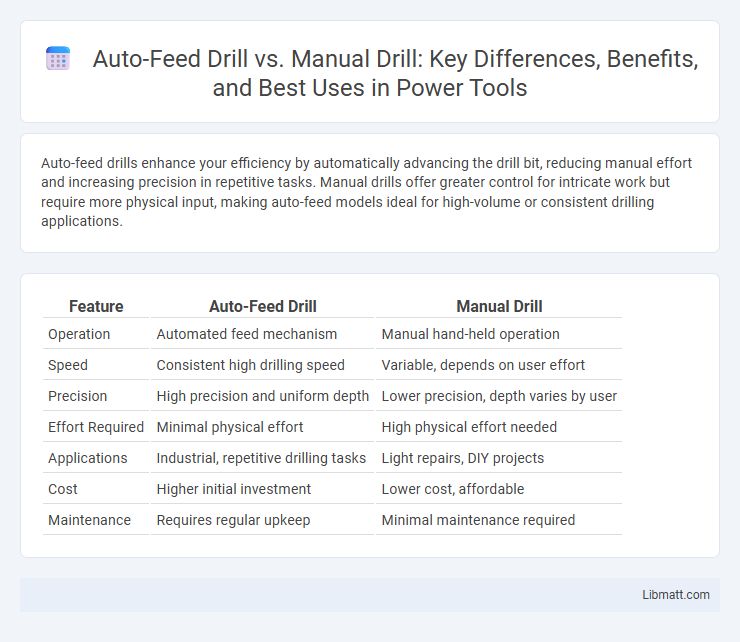

Auto-feed drills enhance your efficiency by automatically advancing the drill bit, reducing manual effort and increasing precision in repetitive tasks. Manual drills offer greater control for intricate work but require more physical input, making auto-feed models ideal for high-volume or consistent drilling applications.

Table of Comparison

| Feature | Auto-Feed Drill | Manual Drill |

|---|---|---|

| Operation | Automated feed mechanism | Manual hand-held operation |

| Speed | Consistent high drilling speed | Variable, depends on user effort |

| Precision | High precision and uniform depth | Lower precision, depth varies by user |

| Effort Required | Minimal physical effort | High physical effort needed |

| Applications | Industrial, repetitive drilling tasks | Light repairs, DIY projects |

| Cost | Higher initial investment | Lower cost, affordable |

| Maintenance | Requires regular upkeep | Minimal maintenance required |

Introduction to Drilling Technologies

Auto-feed drills enhance precision and efficiency by automatically controlling feed rate and depth, reducing operator fatigue and increasing consistency in repetitive tasks. Manual drills rely heavily on user skill for accuracy and speed, offering greater flexibility for varied applications but requiring more physical effort and attention. Advanced auto-feed mechanisms integrate digital controls and sensors, optimizing drilling performance for industrial and high-volume production environments.

What is an Auto-Feed Drill?

An auto-feed drill is a power tool designed to automate the drilling process by combining drilling and feeding actions into a single, continuous motion, enhancing precision and efficiency in repetitive drilling tasks. Unlike manual drills, auto-feed drills feature mechanisms that control the drill bit's advance into the material, maintaining consistent speed and pressure to ensure uniform hole depth and quality. This tool is commonly used in industrial and manufacturing settings where high-volume drilling is required, reducing operator fatigue and improving productivity.

What is a Manual Drill?

A manual drill is a hand-operated tool designed for creating holes in various materials without the need for electricity or batteries. It offers precise control and is ideal for small-scale projects or areas without power access. Choosing a manual drill allows you to maintain accuracy while reducing noise and energy consumption during your drilling tasks.

Key Differences Between Auto-Feed and Manual Drills

Auto-feed drills feature a motorized feed mechanism that ensures consistent pressure and depth, enhancing precision and reducing operator fatigue, while manual drills rely entirely on user force and control. Auto-feed systems are commonly used in production environments requiring high repeatability, whereas manual drills provide greater flexibility for varied or intricate tasks. The motorized feed in auto-feed drills typically leads to faster drilling speeds and improved safety compared to manual operation.

Speed and Efficiency Comparison

Auto-feed drills significantly outperform manual drills in speed and efficiency by automating the feed rate, allowing for consistent and rapid drilling without operator fatigue. With precise control over feed pressure and rotation speed, auto-feed drills optimize hole quality and reduce cycle times, making them ideal for repetitive or high-volume tasks. Your projects benefit from increased productivity and minimized downtime when using auto-feed drill systems compared to manual alternatives.

Precision and Consistency Analysis

Auto-feed drills provide superior precision and consistency compared to manual drills due to their automated feed mechanism, which maintains uniform pressure and drilling speed. This automation reduces human error and ensures exact hole depths and diameters, critical in industrial applications requiring high repeatability. Manual drills rely heavily on operator skill, often resulting in variable hole quality and lower consistency across multiple workpieces.

Applications Best Suited for Each Drill Type

Auto-feed drills excel in repetitive, high-volume drilling tasks commonly found in manufacturing and metal fabrication, where precision and efficiency are critical. Manual drills are best suited for smaller projects, maintenance work, or applications requiring flexibility in tight spaces and varied angles. Your choice depends on whether you prioritize speed and consistency or versatility and control in drilling operations.

Cost and Maintenance Considerations

Auto-feed drills generally have higher upfront costs due to advanced mechanisms and electronic components, while manual drills are more affordable and accessible for basic tasks. Maintenance for auto-feed drills involves regular calibration and potential electronic repairs, increasing long-term expenses compared to the simpler mechanical upkeep of manual drills. Budget-sensitive projects benefit from manual drills, whereas professional environments may justify the investment in auto-feed models for efficiency despite higher maintenance costs.

Safety Features and User Experience

Auto-feed drills incorporate advanced safety features such as automatic clutch engagement and overload protection, minimizing the risk of operator injury. These drills enhance user experience by reducing physical strain and maintaining consistent feed pressure, resulting in more precise drilling. Manual drills offer greater control for delicate tasks but require more physical effort and pose higher injury risks without built-in safety mechanisms.

Choosing the Right Drill for Your Needs

Auto-feed drills offer consistent feed rate control and higher precision, ideal for repetitive tasks and industrial use, while manual drills provide flexibility and control suited for varied, smaller-scale projects. Your choice depends on the volume and accuracy required; auto-feed drills enhance productivity for large batches, whereas manual drills allow more nuanced handling for custom jobs. Evaluating the specific demands of your tasks ensures you select the drill that best matches your workflow and efficiency needs.

Auto-feed drill vs manual drill Infographic

libmatt.com

libmatt.com