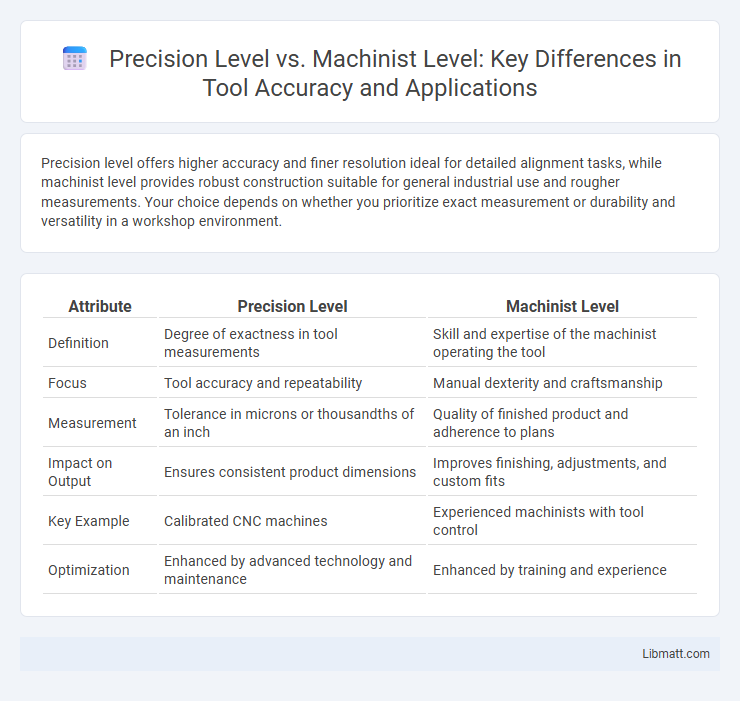

Precision level offers higher accuracy and finer resolution ideal for detailed alignment tasks, while machinist level provides robust construction suitable for general industrial use and rougher measurements. Your choice depends on whether you prioritize exact measurement or durability and versatility in a workshop environment.

Table of Comparison

| Attribute | Precision Level | Machinist Level |

|---|---|---|

| Definition | Degree of exactness in tool measurements | Skill and expertise of the machinist operating the tool |

| Focus | Tool accuracy and repeatability | Manual dexterity and craftsmanship |

| Measurement | Tolerance in microns or thousandths of an inch | Quality of finished product and adherence to plans |

| Impact on Output | Ensures consistent product dimensions | Improves finishing, adjustments, and custom fits |

| Key Example | Calibrated CNC machines | Experienced machinists with tool control |

| Optimization | Enhanced by advanced technology and maintenance | Enhanced by training and experience |

Introduction to Precision Levels and Machinist Levels

Precision levels and machinist levels are essential tools used to measure and ensure accuracy in various engineering and manufacturing processes. Precision levels offer higher sensitivity with fine graduations, allowing for exact leveling in applications requiring minimal tolerance deviations. Your choice between precision and machinist levels depends on the degree of accuracy needed, with machinist levels typically used for general machine setup and alignment tasks, while precision levels are favored for critical measurement tasks demanding superior accuracy.

Defining Precision Level: Features and Uses

A precision level is a highly accurate measuring instrument designed for tasks requiring tight tolerance and fine adjustments, commonly used in machining, laboratory work, and calibration. It features a sensitive vial with a fine gradation, often capable of detecting minute angular deviations down to arc seconds or thousandths of an inch per foot. Your work benefits from precision levels when exact leveling is critical, unlike machinist levels that prioritize durability and versatility for general workshop applications.

What is a Machinist Level? Key Characteristics

A machinist level is a precision instrument used to measure small variations in a surface's angle, often with an accuracy of one arc second or better. Key characteristics include a high-resolution bubble vial or electronic sensor, a rigid and stable frame for minimal deformation, and adjustable leveling screws for fine calibration. This tool is essential in machine setup, alignment, and calibration tasks where maintaining exact horizontal or vertical alignment is critical.

Comparing Accuracy: Precision Level vs Machinist Level

Precision levels offer superior accuracy with tolerance measurements typically within thousandths of an inch, making them ideal for delicate alignment tasks. Machinist levels, while slightly less precise, provide reliable readings centered around two to five thousandths of an inch, suitable for general machine setup and assembly work. The key distinction lies in the precision level's enhanced sensitivity, which ensures higher accuracy for fine calibration compared to the broader measurement range of machinist levels.

Construction Material Differences

Precision level instruments typically feature higher-grade construction materials such as hardened stainless steel and borosilicate glass vials, enhancing durability and resistance to corrosion. Machinist levels often use robust aluminum or brass bodies designed to withstand heavy workshop use while maintaining accuracy. The choice of materials directly influences the tool's stability, lifespan, and measurement reliability in various industrial environments.

Applications in Industrial Settings

Precision level tools offer high accuracy measurements essential for calibration and alignment in advanced manufacturing, ensuring machinery operates at optimal tolerances. Machinist levels, while still accurate, are designed for broader use in metalworking and machine setup to maintain basic flatness and levelness during assembly. Your choice between precision and machinist levels depends on the specific industrial application and the required measurement sensitivity.

Precision Level vs Machinist Level: Cost Comparison

Precision levels typically cost more than machinist levels due to their higher accuracy and advanced calibration standards essential for critical measurements in engineering and scientific applications. Machinist levels, while still precise, offer a more budget-friendly option suitable for general workshop tasks without the extreme tolerance requirements. Your choice between the two should consider the specific precision needs of your project balanced against the available budget.

Maintenance and Calibration Requirements

Precision level instruments demand rigorous maintenance and frequent calibration to ensure accurate measurements in high-tolerance environments, often requiring traceable standards and environmental controls. Machinist levels, while still requiring regular maintenance, typically have less stringent calibration intervals and may tolerate minor deviations due to their application in general machinery setup and alignment. Proper calibration schedules for precision levels often involve professional calibration services, whereas machinist levels can sometimes be calibrated in-house using reference surfaces or master levels.

Selecting the Right Tool for Your Project

Selecting the right tool for your project requires understanding the distinction between precision level and machinist level tools. Precision levels offer accuracy within thousandths of an inch, ideal for fine alignment and detailed measurements in woodworking or engineering. Machinist level tools provide even greater accuracy, often to ten-thousandths of an inch, making them essential for metalworking and high-precision machinery setups.

Conclusion: Choosing Between Precision and Machinist Levels

Precision levels provide extremely accurate measurements with sensitivity often reaching 0.0005 degrees, making them ideal for tasks requiring high accuracy such as calibration and fine instrument setup. Machinist levels, while less sensitive with typical resolutions around 0.005 degrees, offer robust construction suited for general machinery alignment and setup. Selecting between precision and machinist levels depends on the application's accuracy requirements, environmental factors, and budget constraints.

Precision level vs machinist level Infographic

libmatt.com

libmatt.com