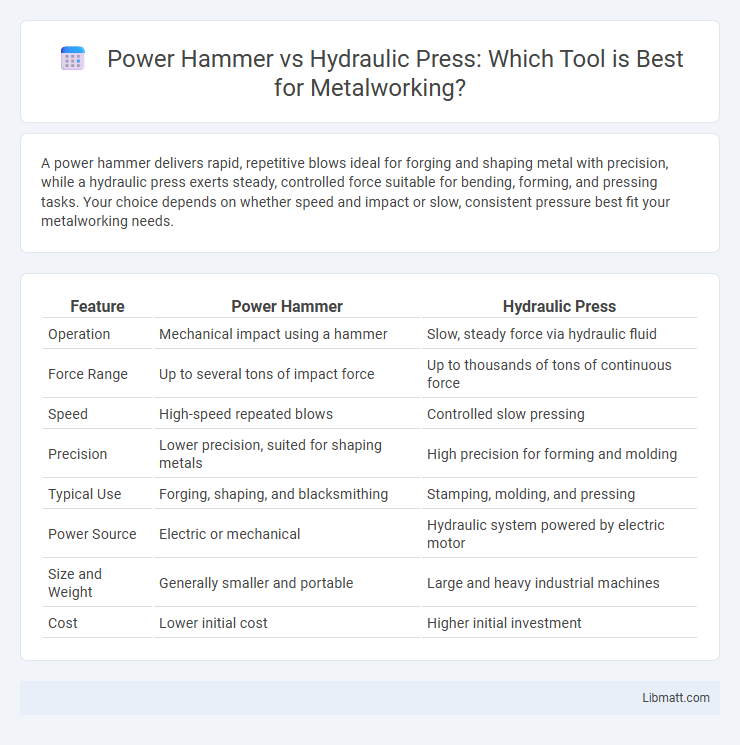

A power hammer delivers rapid, repetitive blows ideal for forging and shaping metal with precision, while a hydraulic press exerts steady, controlled force suitable for bending, forming, and pressing tasks. Your choice depends on whether speed and impact or slow, consistent pressure best fit your metalworking needs.

Table of Comparison

| Feature | Power Hammer | Hydraulic Press |

|---|---|---|

| Operation | Mechanical impact using a hammer | Slow, steady force via hydraulic fluid |

| Force Range | Up to several tons of impact force | Up to thousands of tons of continuous force |

| Speed | High-speed repeated blows | Controlled slow pressing |

| Precision | Lower precision, suited for shaping metals | High precision for forming and molding |

| Typical Use | Forging, shaping, and blacksmithing | Stamping, molding, and pressing |

| Power Source | Electric or mechanical | Hydraulic system powered by electric motor |

| Size and Weight | Generally smaller and portable | Large and heavy industrial machines |

| Cost | Lower initial cost | Higher initial investment |

Introduction to Power Hammers and Hydraulic Presses

Power hammers deliver rapid, repetitive impact force ideal for shaping metal through forging, while hydraulic presses provide precise, controlled pressure for forming and molding materials. Power hammers are commonly used in blacksmithing and metal forging due to their high-speed striking capabilities, whereas hydraulic presses excel in applications requiring consistent pressure and slow compression. Understanding the distinct functions and operational mechanisms of these tools helps you select the right equipment for your metalworking needs.

Key Differences Between Power Hammers and Hydraulic Presses

Power hammers deliver rapid, repetitive striking force ideal for shaping metals with high impact energy and speed, whereas hydraulic presses apply steady, controlled pressure suitable for precision forming and molding tasks. Power hammers excel in forging applications requiring dynamic force and are typically pneumatically or mechanically driven, while hydraulic presses use fluid power for smooth, adjustable pressure over extended durations. The choice between the two depends on the specific metalworking requirements, with power hammers favored for hot forging and hydraulic presses preferred for tasks demanding consistent force and fine control.

How Power Hammers Work: Principles and Applications

Power hammers operate by converting air or steam pressure into rapid, repetitive striking force, making them ideal for shaping and forging metals with precision and speed. Their mechanical ram delivers controlled impact energy, allowing skilled blacksmiths to manipulate metal efficiently compared to slower, less consistent manual hammering. Your shop can benefit from power hammers when working on detailed forging projects requiring both force and finesse.

Hydraulic Press Mechanics: Features and Functionality

Hydraulic presses operate using Pascal's principle, where hydraulic fluid transmits pressure evenly through a confined space to generate substantial force with minimal input effort. Key features include a piston-cylinder mechanism, a hydraulic pump, and control valves enabling precise force application and speed regulation. This functionality allows hydraulic presses to perform consistent, high-pressure tasks such as metal forming, molding, and compression with superior control and efficiency compared to mechanical power hammers.

Efficiency and Speed: Comparing Power Hammers vs Hydraulic Presses

Power hammers deliver rapid, repetitive blows suitable for shaping metals quickly, making them highly efficient for tasks requiring speed and rhythmic force. Hydraulic presses offer precise, consistent pressure with adjustable force, ideal for controlled, slower operations where accuracy is paramount. Understanding your project's demands helps you choose between the power hammer's speed and the hydraulic press's efficiency in force application.

Versatility and Usage Scenarios in Metalworking

Power hammers excel in rapid, repetitive forging tasks, ideal for shaping and drawing out metal in blacksmithing and artistic applications. Hydraulic presses deliver controlled, consistent pressure, making them better suited for precise metal forming, bending, and straightening in industrial fabrication. Choosing between them depends on the required force control and the specific metalworking processes involved.

Precision and Control: Which Tool Performs Better?

Hydraulic presses offer superior precision and control due to their ability to apply consistent, adjustable pressure with fine-tuned accuracy, making them ideal for delicate or complex tasks. Power hammers deliver rapid, repetitive force but lack the same level of control, often producing variable impact intensity depending on operator skill. For your projects demanding exactness, hydraulic presses outperform power hammers by providing consistent force and enhanced process regulation.

Cost Analysis: Investment, Maintenance, and Operation

Power hammers generally require a lower initial investment compared to hydraulic presses, making them more accessible for small to mid-sized workshops. Maintenance costs for power hammers tend to be higher due to frequent mechanical wear and the need for regular lubrication, while hydraulic presses demand less routine upkeep but may incur expensive repairs if hydraulic components fail. Operational expenses vary, with power hammers consuming more energy through repetitive mechanical impacts, whereas hydraulic presses offer more efficient energy use and precise control, potentially reducing overall operating costs for Your production needs.

Safety Considerations for Power Hammers and Hydraulic Presses

Power hammers and hydraulic presses each pose distinct safety considerations crucial for preventing workplace accidents. Power hammers require rigorous guarding and strict adherence to operational procedures due to rapid, repeated hammering motions that can cause serious injury. Your safety when using hydraulic presses depends on proper maintenance of pressure systems, effective use of safety shields, and emergency stop mechanisms to avoid crushing injuries.

Choosing the Right Tool: Factors to Consider

Choosing between a power hammer and a hydraulic press depends on your specific metalworking needs, including the type of material, desired precision, and project scale. Power hammers are ideal for shaping and forging with rapid, repetitive strikes, providing speed and flexibility, while hydraulic presses excel in delivering consistent, controlled pressure for tasks requiring precision and uniformity. Evaluate factors such as force requirements, operational speed, workspace availability, and budget to determine which tool best supports your production efficiency and quality goals.

Power hammer vs hydraulic press Infographic

libmatt.com

libmatt.com