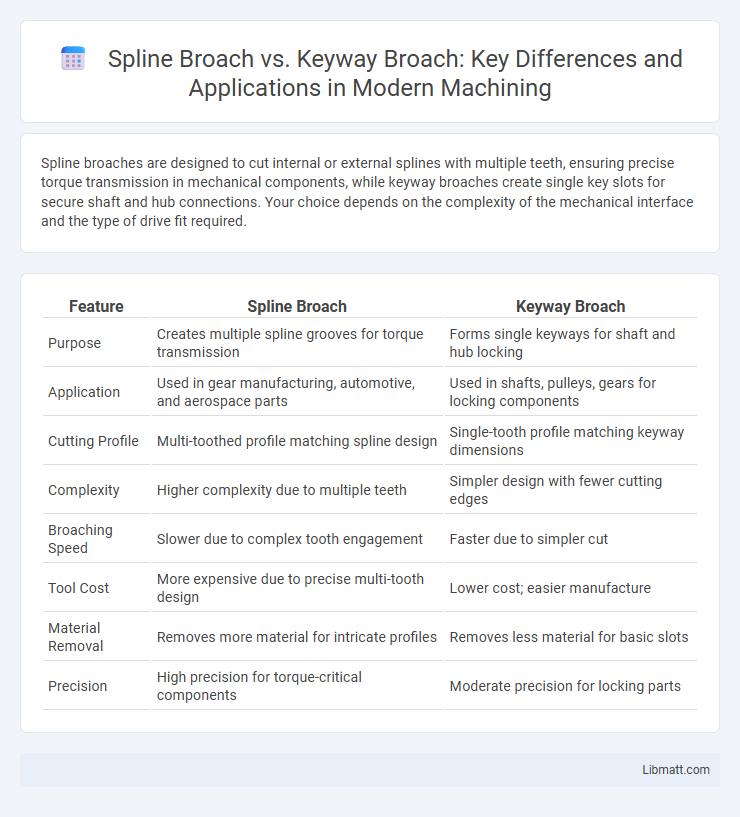

Spline broaches are designed to cut internal or external splines with multiple teeth, ensuring precise torque transmission in mechanical components, while keyway broaches create single key slots for secure shaft and hub connections. Your choice depends on the complexity of the mechanical interface and the type of drive fit required.

Table of Comparison

| Feature | Spline Broach | Keyway Broach |

|---|---|---|

| Purpose | Creates multiple spline grooves for torque transmission | Forms single keyways for shaft and hub locking |

| Application | Used in gear manufacturing, automotive, and aerospace parts | Used in shafts, pulleys, gears for locking components |

| Cutting Profile | Multi-toothed profile matching spline design | Single-tooth profile matching keyway dimensions |

| Complexity | Higher complexity due to multiple teeth | Simpler design with fewer cutting edges |

| Broaching Speed | Slower due to complex tooth engagement | Faster due to simpler cut |

| Tool Cost | More expensive due to precise multi-tooth design | Lower cost; easier manufacture |

| Material Removal | Removes more material for intricate profiles | Removes less material for basic slots |

| Precision | High precision for torque-critical components | Moderate precision for locking parts |

Introduction to Spline Broaches and Keyway Broaches

Spline broaches are precision cutting tools designed to create multiple evenly spaced grooves inside a hole, enabling torque transfer in mechanical components such as gears and shafts. Keyway broaches cut a single keyway slot, facilitating the secure attachment of machine elements like pulleys or couplings to a shaft. Both spline and keyway broaches are essential in machining processes, offering high accuracy and efficiency for internal profile creation.

Definition and Basic Functionality

Spline broach is a cutting tool designed to create internal or external spline profiles used for transmitting torque between shafts and mechanical components. Keyway broach forms keyways--rectangular slots--inside bores or shafts to accommodate keys that secure rotating parts, preventing relative motion. Both tools operate by precision material removal but target distinct mechanical joint geometries critical in power transmission systems.

Design Differences: Spline Broach vs Keyway Broach

Spline broaches feature multiple cutting edges arranged to create precise spline profiles with uniform grooves, enabling efficient torque transmission in mechanical components. Keyway broaches have a single cutting edge designed to produce a specific slot or keyway for securing rotating parts on shafts. The design of spline broaches allows for simultaneous cutting of multiple splines, while keyway broaches focus on creating a singular groove with tight dimensional control for alignment and power transfer.

Typical Applications in Industry

Spline broaches are commonly used in automotive and aerospace industries to manufacture precise internal splines for gears, shafts, and couplings, ensuring high torque transmission and alignment accuracy. Keyway broaches find widespread application in mechanical engineering sectors for creating keyways in shafts and hubs, facilitating secure component assembly and power transfer in machinery. Both broach types are essential in heavy equipment, manufacturing, and power transmission industries where reliability and precision are critical.

Material Compatibility

Spline broaches excel in cutting complex profiles on tougher materials like hardened steel and titanium alloys, providing precise and smooth tooth forms. Keyway broaches work effectively on softer metals such as aluminum, brass, and mild steel, where simple slot cutting is required without high stress resistance. Material compatibility dictates tool selection, as spline broaches handle high-strength alloys with tighter tolerance demands, while keyway broaches suit less challenging materials and applications.

Manufacturing Process and Precision

Spline broaching involves cutting multiple spline teeth simultaneously using a form tool, producing high-precision, uniform profiles ideal for transmission shafts and gears. Keyway broaching uses a linear cut to create a single key slot, offering simpler tooling but less complexity and slightly lower precision compared to spline broaching. Both processes require precise setup and rigid machine conditions, but spline broaches generally achieve tighter tolerances and smoother finishes critical for high-performance mechanical assemblies.

Advantages of Spline Broaching

Spline broaching offers precise and efficient cutting of internal splines with minimal material waste and improved surface finish compared to keyway broaching. This method provides enhanced load distribution and torque transmission in mechanical assemblies, leading to greater component durability. Your production process benefits from faster cycle times and reduced tooling wear when using spline broaching techniques.

Benefits of Keyway Broaching

Keyway broaching offers precise and consistent keyways critical for secure mechanical connections, enhancing torque transmission in shafts and gears. This method reduces machining time and improves production efficiency by enabling high-speed, automated operations with minimal tool wear. Your manufacturing process benefits from cost-effective, repeatable keyway cuts that ensure optimal fit and alignment in assembly applications.

Cost Considerations and Efficiency

Spline broaches typically have a higher initial cost due to their complex design and precision requirements, but they offer greater efficiency by producing high-quality, uniform splines in fewer passes. Keyway broaches are generally more affordable upfront and simpler to use, making them cost-effective for lower-volume or less intricate applications. Your choice depends on balancing budget constraints with production volume and the precision needed, where spline broaches often yield better long-term efficiency despite higher initial expenses.

Choosing the Right Broaching Tool

Selecting the appropriate broaching tool depends on the specific application requirements such as torque transmission and load capacity. Spline broaches create multiple teeth for enhanced mechanical power transfer in high-stress environments, making them ideal for automotive and heavy machinery parts. Keyway broaches are better suited for simpler shafts requiring single-slot features for component positioning or torque restraint in lighter-duty assemblies.

Spline broach vs keyway broach Infographic

libmatt.com

libmatt.com