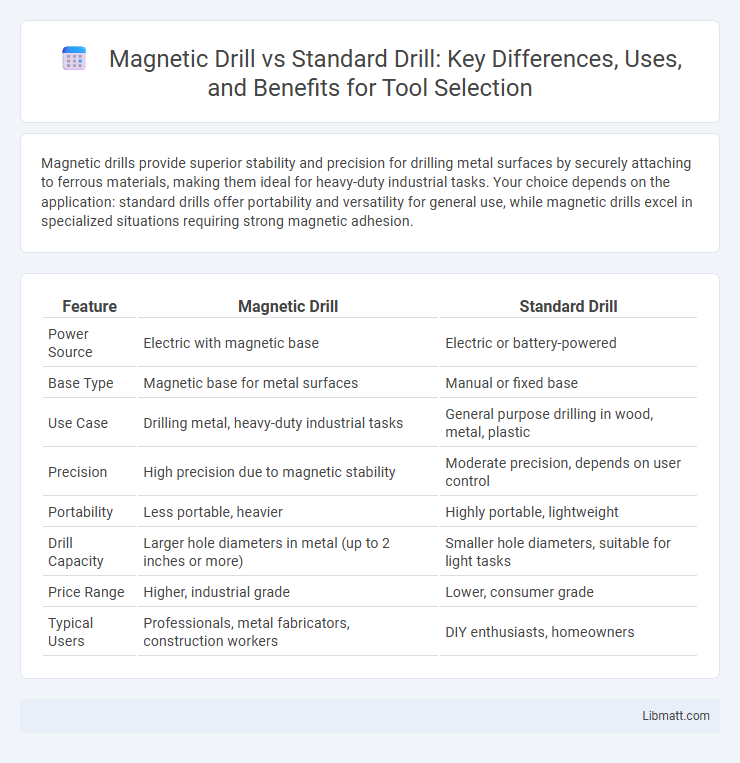

Magnetic drills provide superior stability and precision for drilling metal surfaces by securely attaching to ferrous materials, making them ideal for heavy-duty industrial tasks. Your choice depends on the application: standard drills offer portability and versatility for general use, while magnetic drills excel in specialized situations requiring strong magnetic adhesion.

Table of Comparison

| Feature | Magnetic Drill | Standard Drill |

|---|---|---|

| Power Source | Electric with magnetic base | Electric or battery-powered |

| Base Type | Magnetic base for metal surfaces | Manual or fixed base |

| Use Case | Drilling metal, heavy-duty industrial tasks | General purpose drilling in wood, metal, plastic |

| Precision | High precision due to magnetic stability | Moderate precision, depends on user control |

| Portability | Less portable, heavier | Highly portable, lightweight |

| Drill Capacity | Larger hole diameters in metal (up to 2 inches or more) | Smaller hole diameters, suitable for light tasks |

| Price Range | Higher, industrial grade | Lower, consumer grade |

| Typical Users | Professionals, metal fabricators, construction workers | DIY enthusiasts, homeowners |

Introduction: Magnetic Drill vs Standard Drill

A magnetic drill features a powerful electromagnetic base that clamps securely to metal surfaces, providing superior stability and precision compared to a standard drill. Standard drills rely on manual pressure and are versatile for various materials but lack the specialized holding capacity for heavy-duty metal drilling. Magnetic drills excel in industrial applications where accuracy and repeatability on steel structures are critical.

Core Functions and Applications

Magnetic drills specialize in drilling precise, large-diameter holes in steel and other ferromagnetic metals, featuring a powerful electromagnetic base that secures the drill to metal surfaces for stability and accuracy. Standard drills offer versatility for general-purpose drilling on materials like wood, plastic, and metal, but lack the magnetic base, limiting their precision on vertical or overhead steel surfaces. Magnetic drills are essential for industrial applications such as construction, shipbuilding, and metal fabrication where secure positioning and deep core drilling on steel are required.

Design and Build Differences

Magnetic drills feature a powerful electromagnetic base that anchors the tool securely to ferrous metal surfaces, allowing for precise vertical drilling in industrial and construction settings. Standard drills have a handheld design with no magnetic base, making them more versatile for general use but less stable on metal surfaces. Your choice depends on whether you need the stability and precision of a magnetic drill or the flexibility of a standard drill for everyday tasks.

Portability and Mobility

Magnetic drills are generally bulkier and heavier due to their built-in magnetic base, which limits portability but provides superior stability for heavy-duty drilling on steel surfaces. Standard drills are lighter, more compact, and battery-powered options enhance their mobility, making them ideal for a variety of job sites and quick tasks. Your choice depends on whether you prioritize ease of transport for versatile drilling or fixed precision when working on ferrous metal.

Precision and Accuracy

Magnetic drills provide superior precision and accuracy compared to standard drills due to their strong electromagnetic base that securely anchors the tool to ferrous metal surfaces, minimizing movement during operation. This stability results in cleaner, more precise holes, especially in vertical or overhead drilling situations. Standard drills lack this secure attachment, which can lead to less control and increased margin of error in hole placement and depth.

Material Compatibility

Magnetic drills excel in drilling ferrous metals due to their strong electromagnetic base, providing stability and precision on steel and iron surfaces. Standard drills are more versatile, capable of working on a wider range of materials including wood, plastic, and non-ferrous metals but lack the magnetic base for secure attachment on metal surfaces. Choosing between magnetic and standard drills depends on the material: magnetic drills offer superior performance on ferrous metals, while standard drills cater to diverse materials with varying hardness and thickness.

Power and Performance

Magnetic drills provide significantly higher power and performance compared to standard drills, featuring robust motors designed for heavy-duty metalworking and precise drilling on steel surfaces. Their electromagnetic base ensures stability, allowing for consistent torque and deeper hole drilling without slippage, which standard drills often struggle to maintain. This combination of superior motor strength and secure attachment makes magnetic drills ideal for industrial applications demanding precision and efficiency.

Safety Features and Considerations

Magnetic drills offer enhanced safety features compared to standard drills, including a strong electromagnetic base that securely anchors the tool to metal surfaces, reducing the risk of slippage and injury during operation. These drills often include overload protection systems and heat sensors to prevent motor damage and user accidents. Your safety is further improved by the precision and stability provided, making magnetic drills ideal for heavy-duty metalworking tasks where control is critical.

Cost and Investment Analysis

Magnetic drills typically require a higher initial investment compared to standard drills due to their specialized design and powerful magnetic base, which ensures precision and safety on metal surfaces. Your cost analysis should consider the long-term benefits of increased productivity and reduced operator fatigue, which can offset the upfront expense through improved efficiency in industrial applications. Standard drills, while more affordable upfront, may incur higher operational costs over time due to less stability and slower drilling speed on metal, impacting overall return on investment.

Choosing the Right Drill for Your Project

Magnetic drills provide superior stability and precision on metal surfaces due to their powerful electromagnetic base, making them ideal for heavy-duty construction or fabrication projects. Standard drills offer greater versatility and ease of use on various materials, suitable for general household tasks or lighter work. Choosing the right drill depends on your project's specific needs, such as material type, drilling accuracy, and portability requirements.

Magnetic drill vs standard drill Infographic

libmatt.com

libmatt.com