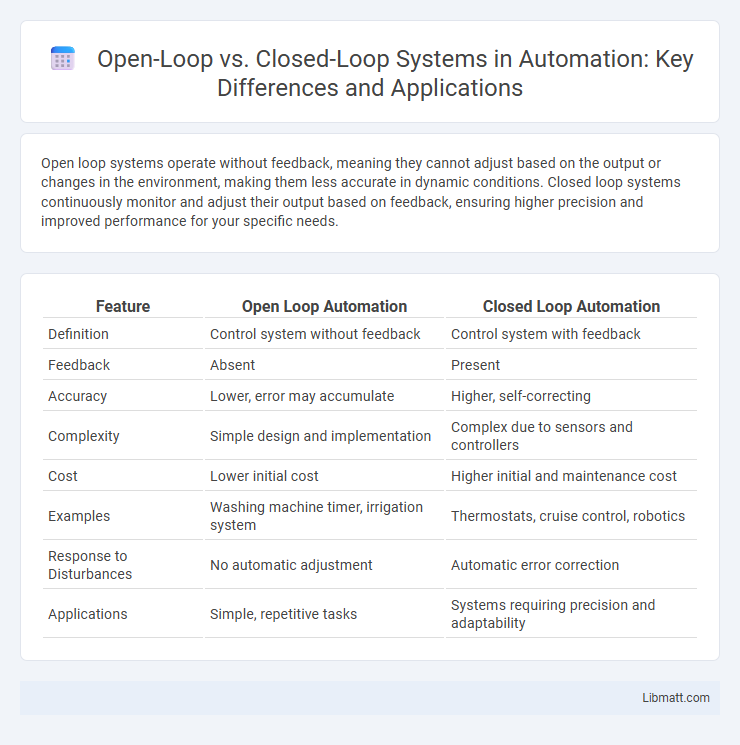

Open loop systems operate without feedback, meaning they cannot adjust based on the output or changes in the environment, making them less accurate in dynamic conditions. Closed loop systems continuously monitor and adjust their output based on feedback, ensuring higher precision and improved performance for your specific needs.

Table of Comparison

| Feature | Open Loop Automation | Closed Loop Automation |

|---|---|---|

| Definition | Control system without feedback | Control system with feedback |

| Feedback | Absent | Present |

| Accuracy | Lower, error may accumulate | Higher, self-correcting |

| Complexity | Simple design and implementation | Complex due to sensors and controllers |

| Cost | Lower initial cost | Higher initial and maintenance cost |

| Examples | Washing machine timer, irrigation system | Thermostats, cruise control, robotics |

| Response to Disturbances | No automatic adjustment | Automatic error correction |

| Applications | Simple, repetitive tasks | Systems requiring precision and adaptability |

Introduction to Open Loop and Closed Loop Systems

Open loop systems operate without feedback, executing predefined inputs regardless of output changes, commonly seen in simple devices like toasters. Closed loop systems continuously monitor output through sensors, adjusting inputs dynamically to achieve desired performance, as exemplified by thermostats regulating temperature. These control system types are fundamental in engineering, with closed loop offering higher precision and adaptability compared to open loop configurations.

Key Differences Between Open and Closed Loop

Open loop systems operate without feedback, relying solely on predefined inputs to produce outputs, which can lead to less accuracy in dynamic environments. Closed loop systems continuously monitor output through sensors and adjust inputs to maintain desired performance, ensuring higher precision and adaptability. The primary difference lies in feedback utilization--open loops lack it, while closed loops depend on it for control and correction.

How Open Loop Systems Work

Open loop systems operate by sending a predetermined input to a process without using feedback to adjust the output. They rely solely on the initial command, making them simpler and faster but less accurate in changing conditions. Your system's performance depends entirely on precise calibration and stable environmental factors since no corrections are made during operation.

How Closed Loop Systems Work

Closed loop systems function by continuously monitoring output through feedback sensors, comparing it with the desired setpoint to automatically adjust inputs and maintain optimal performance. This feedback mechanism enables real-time corrections, reducing errors caused by disturbances or system variability. The dynamic response of closed loop control enhances accuracy and stability in various applications, including temperature regulation, motor speed control, and process automation.

Advantages of Open Loop Systems

Open loop systems offer simplicity, cost-effectiveness, and faster response times by operating without feedback. Your processes benefit from minimal design complexity and lower maintenance requirements, making them ideal for stable, predictable environments. These systems excel in applications where real-time adjustments aren't critical, ensuring efficiency and reliability.

Advantages of Closed Loop Systems

Closed loop systems offer precise control by continuously monitoring and adjusting outputs based on real-time feedback, which enhances accuracy and stability in various applications. These systems reduce errors, improve response times, and adapt to disturbances, making them highly efficient for complex processes such as industrial automation and temperature regulation. Your operations benefit from increased reliability and optimized performance, reducing downtime and maintenance costs.

Disadvantages of Open Loop Systems

Open loop systems often suffer from lack of feedback, leading to poor accuracy and inability to automatically correct errors. They cannot adapt to disturbances or changes in the environment, resulting in unreliable performance. Maintenance and calibration may be frequently required due to their sensitivity to external factors.

Disadvantages of Closed Loop Systems

Closed loop systems often face disadvantages such as increased complexity and higher costs compared to open loop systems due to the need for feedback sensors and controllers. These systems can suffer from stability issues and slower response times when feedback delays occur, potentially causing oscillations or instability in the control process. Your maintenance requirements may also increase as sensor failures or inaccuracies can lead to incorrect system adjustments and degraded performance.

Applications of Open vs Closed Loop Systems

Open loop systems are commonly used in simple applications like household appliances, such as washing machines and toasters, where the output does not affect the input control. Closed loop systems find extensive applications in critical processes requiring precision and accuracy, including industrial automation, temperature control, and robotics, due to their feedback mechanism that continuously adjusts operations based on output. Your choice between open and closed loop systems depends on the need for control accuracy, complexity, and response time in your specific application.

Choosing the Right System: Open Loop vs Closed Loop

Choosing the right system between open loop and closed loop depends on your control precision and feedback requirements. Open loop systems operate without feedback, making them simpler and cost-effective for applications where accuracy is less critical. Closed loop systems use real-time feedback to adjust performance, ideal for environments demanding high accuracy and adaptability.

Open Loop vs Closed Loop Infographic

libmatt.com

libmatt.com