Sequence control manages the order of operations in automated systems, ensuring tasks occur in a specific, predefined sequence. Process control regulates continuous variables such as temperature, pressure, and flow to maintain desired system performance and product quality.

Table of Comparison

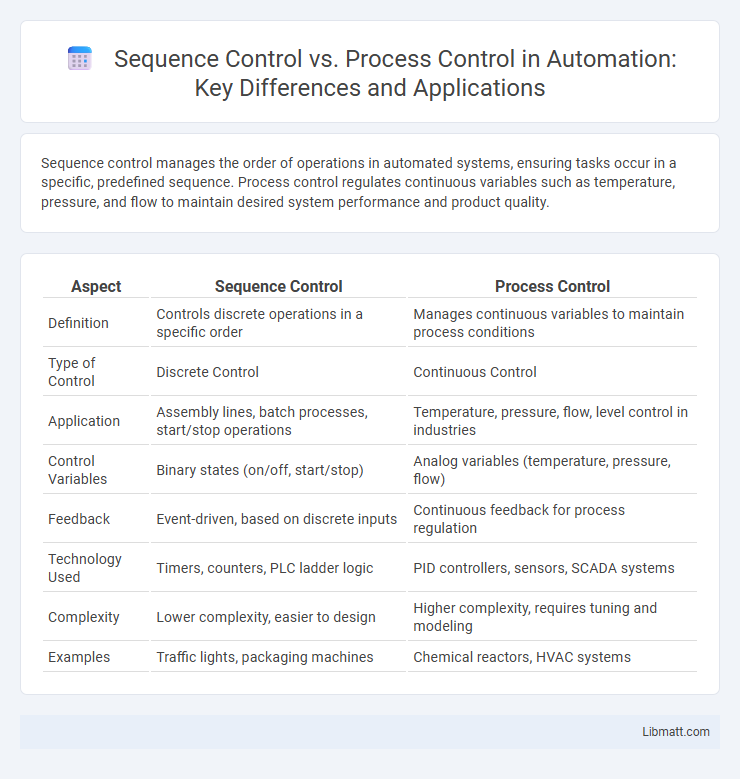

| Aspect | Sequence Control | Process Control |

|---|---|---|

| Definition | Controls discrete operations in a specific order | Manages continuous variables to maintain process conditions |

| Type of Control | Discrete Control | Continuous Control |

| Application | Assembly lines, batch processes, start/stop operations | Temperature, pressure, flow, level control in industries |

| Control Variables | Binary states (on/off, start/stop) | Analog variables (temperature, pressure, flow) |

| Feedback | Event-driven, based on discrete inputs | Continuous feedback for process regulation |

| Technology Used | Timers, counters, PLC ladder logic | PID controllers, sensors, SCADA systems |

| Complexity | Lower complexity, easier to design | Higher complexity, requires tuning and modeling |

| Examples | Traffic lights, packaging machines | Chemical reactors, HVAC systems |

Introduction to Sequence Control and Process Control

Sequence control involves managing discrete operations in a specific order, typically using timers, counters, and relays to execute step-by-step tasks in automation systems. Process control focuses on regulating continuous variables such as temperature, pressure, and flow through feedback loops and control algorithms to maintain system stability and efficiency. Both control methods are fundamental in industrial automation, with sequence control handling event-driven processes and process control optimizing dynamic physical conditions.

Key Definitions: Sequence Control vs Process Control

Sequence control involves managing a set of ordered steps or operations where actions occur in a predefined sequence based on discrete inputs and outputs, often implemented in relay logic or PLC ladder programming. Process control regulates continuous variables such as temperature, pressure, flow, and level by continuously measuring process parameters and adjusting control elements like valves or motors to maintain desired setpoints. The fundamental difference lies in sequence control handling discrete, stepwise operations, whereas process control manages continuous dynamic processes to optimize system performance.

Fundamental Principles of Sequence Control

Sequence control relies on discrete logic to manage the order of operations in automated systems, ensuring precise timing and coordination of machinery. It uses binary signals and predefined steps to trigger specific actions, making it ideal for applications requiring strict procedural workflows. Your system's efficiency improves by minimizing errors through clear, step-by-step process execution inherent to sequence control.

Core Concepts of Process Control

Process control centers on maintaining variables such as temperature, pressure, and flow rate within predefined limits to ensure product quality and system stability. It utilizes feedback loops and sensors to continuously monitor and adjust processes in real-time, aiming for steady-state operation. Unlike sequence control, which manages discrete steps in operations, process control emphasizes dynamic regulation of continuous parameters for optimal performance.

Major Differences Between Sequence and Process Control

Sequence control manages discrete events in a predefined order using logic-based systems like PLCs, focusing on the timing and conditions of individual steps. Process control regulates continuous variables such as temperature, pressure, and flow via feedback loops, ensuring stable operation of physical processes. The primary difference lies in sequence control's event-driven approach versus process control's emphasis on maintaining process parameters within set limits.

Typical Applications of Sequence Control

Sequence control is commonly used in applications requiring precise, step-by-step operation such as automated assembly lines, traffic light systems, and packaging machines. It efficiently manages discrete processes with defined states and transitions, making it ideal for tasks like conveyor belt sorting and robotic arm positioning. Your automation system benefits from sequence control when predictable, ordered sequences are essential for maintaining operational consistency.

Common Use Cases for Process Control

Process control is predominantly used in industries requiring continuous monitoring and regulation of variables such as temperature, pressure, and flow, including chemical manufacturing, oil refining, and food processing. It ensures product quality and operational safety by maintaining stable process conditions within precise limits through feedback loops and control algorithms. Common applications include maintaining fermentation temperatures in pharmaceuticals, controlling boiler steam pressure in power plants, and regulating conveyor speed in automated assembly lines.

Advantages and Limitations of Sequence Control

Sequence control offers precise management of discrete operations, making it ideal for applications involving step-by-step processes such as assembly lines or packaging systems. Its advantages include simplicity, ease of troubleshooting, and cost-effectiveness, especially in systems where operations must occur in a predefined order. Limitations arise when handling complex, continuous processes requiring real-time adjustments or dynamic optimization, which are better suited for process control systems.

Benefits and Challenges of Process Control

Process control offers enhanced precision and efficiency in continuous manufacturing by maintaining optimal operating conditions and reducing variability, which leads to improved product quality and lower waste. It enables real-time adjustments through advanced sensors and feedback loops, supporting complex processes in industries such as chemical production and power generation. However, the challenges include high implementation costs, the need for specialized expertise, and potential difficulties in adapting to process disturbances and equipment failures.

Choosing the Right Control Strategy: Sequence vs Process

Choosing the right control strategy between sequence control and process control depends on the complexity and nature of the application; sequence control uses discrete steps and is ideal for operations with clearly defined events, while process control manages continuous variables like temperature and pressure for maintaining optimal system performance. Sequence control excels in automation tasks such as assembly lines with predefined order, whereas process control is crucial for industries like chemical processing where real-time adjustments are needed to ensure product quality. Understanding system requirements, including timing, variability, and feedback needs, guides the selection of an efficient control method to maximize operational reliability and efficiency.

Sequence Control vs Process Control Infographic

libmatt.com

libmatt.com