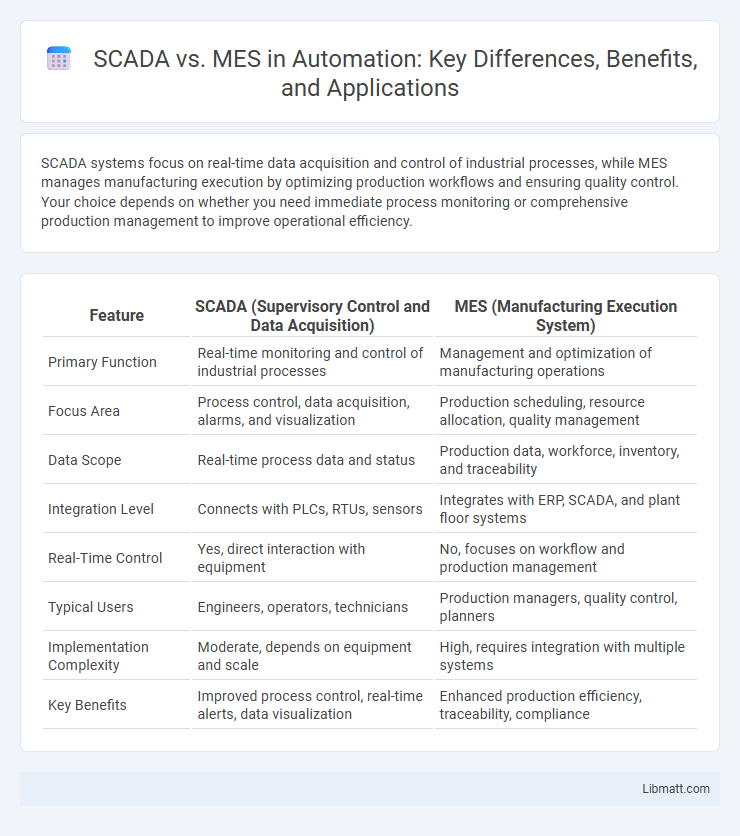

SCADA systems focus on real-time data acquisition and control of industrial processes, while MES manages manufacturing execution by optimizing production workflows and ensuring quality control. Your choice depends on whether you need immediate process monitoring or comprehensive production management to improve operational efficiency.

Table of Comparison

| Feature | SCADA (Supervisory Control and Data Acquisition) | MES (Manufacturing Execution System) |

|---|---|---|

| Primary Function | Real-time monitoring and control of industrial processes | Management and optimization of manufacturing operations |

| Focus Area | Process control, data acquisition, alarms, and visualization | Production scheduling, resource allocation, quality management |

| Data Scope | Real-time process data and status | Production data, workforce, inventory, and traceability |

| Integration Level | Connects with PLCs, RTUs, sensors | Integrates with ERP, SCADA, and plant floor systems |

| Real-Time Control | Yes, direct interaction with equipment | No, focuses on workflow and production management |

| Typical Users | Engineers, operators, technicians | Production managers, quality control, planners |

| Implementation Complexity | Moderate, depends on equipment and scale | High, requires integration with multiple systems |

| Key Benefits | Improved process control, real-time alerts, data visualization | Enhanced production efficiency, traceability, compliance |

Introduction to SCADA and MES

SCADA (Supervisory Control and Data Acquisition) systems enable real-time monitoring and control of industrial processes across manufacturing plants, utilities, and infrastructure. MES (Manufacturing Execution Systems) manage and optimize production workflows, tracking work-in-progress, scheduling, and resource allocation on the factory floor. Both SCADA and MES integrate with ERP systems to enhance operational efficiency and ensure data-driven decision-making in manufacturing environments.

Core Functions of SCADA Systems

SCADA systems primarily monitor and control industrial processes by collecting real-time data from sensors and devices to ensure operational efficiency and safety. Key functions include data acquisition, supervisory control, and alarming for immediate response to system anomalies. These capabilities allow SCADA to provide centralized control over distributed assets, essential for process automation and fault detection.

Key Capabilities of MES Solutions

MES solutions provide real-time production monitoring, work order management, and quality control, ensuring seamless coordination across manufacturing processes. These systems enhance traceability by tracking materials, equipment, and personnel throughout the production lifecycle. Your operational efficiency benefits significantly from MES's ability to integrate data and optimize workflow execution compared to SCADA's primary focus on supervisory control and data acquisition.

SCADA vs MES: Architecture Comparison

SCADA systems focus on real-time data acquisition and control with a distributed architecture designed for monitoring and managing industrial processes through sensors and control devices. MES architecture integrates production workflows and data management, providing a centralized platform that bridges enterprise resource planning (ERP) systems with shop floor operations. Your choice between SCADA and MES depends on whether you need direct process control and visualization or comprehensive production scheduling and quality management.

Data Acquisition and Management

SCADA systems excel at real-time data acquisition, monitoring, and control of industrial processes, providing immediate visibility into equipment status and alarms. MES focuses on comprehensive data management by integrating production data with business processes, enabling detailed tracking, workflow optimization, and reporting. Your choice between SCADA and MES depends on whether you need instant operational control or robust management of manufacturing execution and performance data.

Real-Time Monitoring and Control

SCADA systems provide real-time monitoring and control by collecting live data from sensors and equipment, enabling immediate response to operational changes across industrial processes. MES focuses on integrating real-time production data with manufacturing workflows, optimizing scheduling, resource allocation, and quality control on the factory floor. Together, SCADA ensures process stability while MES drives operational efficiency through detailed production oversight.

Integration with Other Industrial Systems

SCADA systems provide real-time monitoring and control by integrating directly with PLCs and field devices, enabling immediate data acquisition and process automation. MES interfaces with ERP and quality management systems to optimize production scheduling, traceability, and resource management, offering higher-level operational insights. Your choice depends on whether seamless data exchange with shop floor control or enterprise-wide planning is the primary focus.

Application Scenarios: When to Use SCADA or MES

SCADA systems excel in real-time monitoring and control of industrial processes, making them ideal for applications such as water treatment plants, oil and gas pipelines, and power generation where immediate data acquisition and fast response are critical. MES is better suited for managing production workflows, quality control, and resource scheduling in manufacturing environments, enhancing overall production efficiency and traceability. Understanding your operational focus--real-time process supervision or comprehensive production management--will guide whether a SCADA or MES system best supports your industrial automation needs.

Benefits and Limitations of SCADA and MES

SCADA systems excel in real-time monitoring and control of industrial processes, providing rapid data acquisition and immediate response capabilities critical for operational efficiency. MES enhances production management by bridging the gap between enterprise planning and shop floor execution, offering detailed tracking, scheduling, and quality management to improve overall manufacturing performance. Your choice depends on whether the priority is immediate process control with SCADA or comprehensive production optimization with MES, as each has limitations in scope and integration complexity.

Choosing the Right System for Your Industry

Selecting between SCADA and MES depends on your industry's operational needs and scale. SCADA excels in real-time monitoring and control of industrial processes across utilities, manufacturing, and energy sectors, providing immediate data acquisition from sensors and equipment. MES, favored in manufacturing industries such as automotive and pharmaceuticals, optimizes production workflows, quality management, and resource allocation to improve efficiency and traceability on the shop floor.

SCADA vs MES Infographic

libmatt.com

libmatt.com