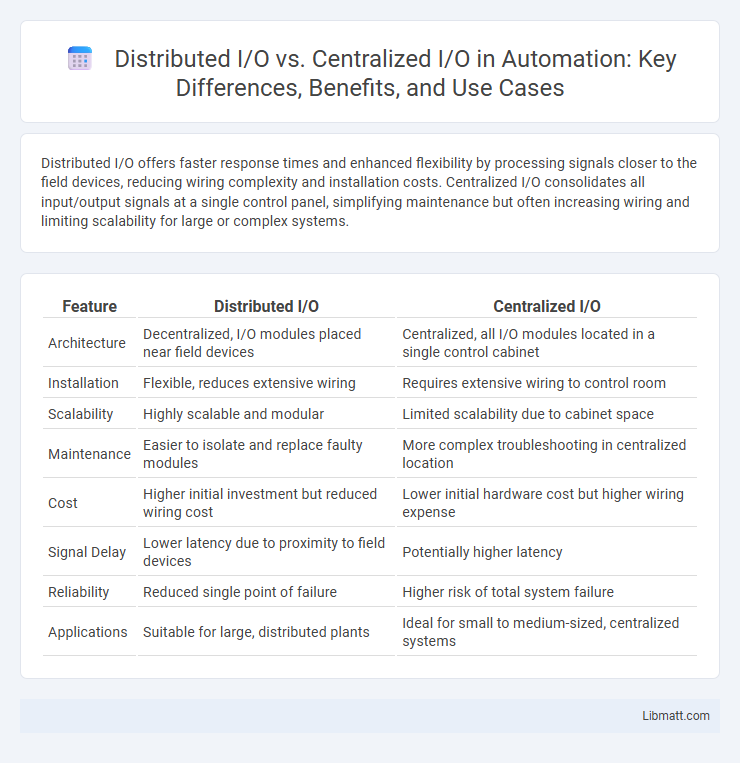

Distributed I/O offers faster response times and enhanced flexibility by processing signals closer to the field devices, reducing wiring complexity and installation costs. Centralized I/O consolidates all input/output signals at a single control panel, simplifying maintenance but often increasing wiring and limiting scalability for large or complex systems.

Table of Comparison

| Feature | Distributed I/O | Centralized I/O |

|---|---|---|

| Architecture | Decentralized, I/O modules placed near field devices | Centralized, all I/O modules located in a single control cabinet |

| Installation | Flexible, reduces extensive wiring | Requires extensive wiring to control room |

| Scalability | Highly scalable and modular | Limited scalability due to cabinet space |

| Maintenance | Easier to isolate and replace faulty modules | More complex troubleshooting in centralized location |

| Cost | Higher initial investment but reduced wiring cost | Lower initial hardware cost but higher wiring expense |

| Signal Delay | Lower latency due to proximity to field devices | Potentially higher latency |

| Reliability | Reduced single point of failure | Higher risk of total system failure |

| Applications | Suitable for large, distributed plants | Ideal for small to medium-sized, centralized systems |

Introduction to I/O Architectures

Distributed I/O architecture decentralizes input/output processing by placing I/O modules closer to sensors and actuators, enhancing system scalability and reducing wiring costs. Centralized I/O architecture consolidates all input/output connections within a single control cabinet, simplifying wiring but potentially increasing cabling complexity and limiting expandability. Choosing between distributed and centralized I/O depends on factors like system size, environmental conditions, installation costs, and maintenance requirements.

What Is Distributed I/O?

Distributed I/O refers to a system architecture where input/output modules are physically located close to field devices and connected through a network to the central controller, reducing wiring complexity and enhancing scalability. This setup improves system reliability by isolating faults to specific nodes and enables faster response times due to local processing. Distributed I/O systems are ideal for large-scale industrial automation where modular expansion and real-time data acquisition are critical for efficient operation.

What Is Centralized I/O?

Centralized I/O refers to a configuration where all input/output devices are connected directly to a single controller or processing unit, allowing simplified management and maintenance. This setup enables faster data processing within a centralized location but can create bottlenecks and single points of failure. Centralized I/O is commonly used in smaller-scale or less complex industrial automation systems requiring tight control and monitoring.

Key Differences Between Distributed and Centralized I/O

Distributed I/O systems place input and output modules closer to field devices, reducing wiring complexity and enhancing system scalability, while centralized I/O consolidates all I/O modules within a single control cabinet, simplifying maintenance but increasing cabling and installation costs. Distributed I/O offers improved fault tolerance and faster response times due to localized processing, whereas centralized I/O may experience delays from longer signal transmission paths. Your choice between distributed and centralized I/O depends on factors like system size, installation environment, and required flexibility.

System Architecture and Scalability

Distributed I/O architecture decentralizes input/output modules closer to field devices, reducing wiring complexity and improving data processing speed, which enhances system scalability by allowing easy expansion across remote locations. Centralized I/O systems concentrate all input/output modules at a single control panel, simplifying maintenance but potentially creating bottlenecks and limiting scalability due to increased wiring and space constraints. Your choice between these architectures impacts the flexibility and growth potential of industrial automation systems, with distributed I/O offering superior adaptability for large-scale or geographically dispersed setups.

Reliability and Fault Tolerance Comparison

Distributed I/O systems enhance reliability by isolating faults to specific modules, reducing the risk of complete system failure compared to centralized I/O architectures where a single point of failure can disrupt the entire network. Fault tolerance in distributed I/O is improved through redundancy and localized error handling, enabling faster fault detection and recovery without affecting overall system performance. Centralized I/O systems often require complex backup solutions to achieve similar fault tolerance levels, making distributed setups more robust for critical industrial automation environments.

Performance and Latency Considerations

Distributed I/O systems reduce latency by processing signals closer to field devices, enhancing real-time performance in industrial automation. Centralized I/O can introduce delays due to longer wiring and centralized processing, potentially impacting time-sensitive applications. Selecting distributed architecture optimizes throughput and response times, crucial for high-speed control environments.

Implementation Complexity and Maintenance

Distributed I/O systems reduce implementation complexity by decentralizing control, allowing easier integration of remote field devices and minimizing extensive wiring costs. Centralized I/O setups concentrate all inputs and outputs in a single location, which simplifies troubleshooting but can lead to higher maintenance challenges due to cable management and potential single points of failure. Your choice depends on balancing ease of expansive system upgrades with the maintenance benefits of centralized diagnostics.

Typical Use Cases and Industry Applications

Distributed I/O systems are ideal for expansive industrial environments such as oil and gas platforms, large manufacturing plants, and water treatment facilities, where remote data acquisition and control reduce wiring complexity and enhance system scalability. Centralized I/O is commonly used in compact automation setups like small to medium-sized manufacturing cells, testing laboratories, and machine tools, offering simplified maintenance and centralized data processing. The choice between distributed and centralized I/O hinges on factors including distance, complexity, and the need for modular expansion within sectors like automotive, pharmaceuticals, and food and beverage processing.

Choosing the Right I/O System for Your Needs

Distributed I/O systems enhance flexibility and scalability by placing input/output modules closer to field devices, reducing wiring complexity and installation costs in large or geographically dispersed setups. Centralized I/O configurations, on the other hand, simplify maintenance and troubleshooting through a single control panel, benefiting applications with limited space and consistent environmental conditions. Selecting the right I/O system depends on factors like system size, distance from control units, budget constraints, and the need for modular expansion or simplified diagnostics.

Distributed I/O vs Centralized I/O Infographic

libmatt.com

libmatt.com