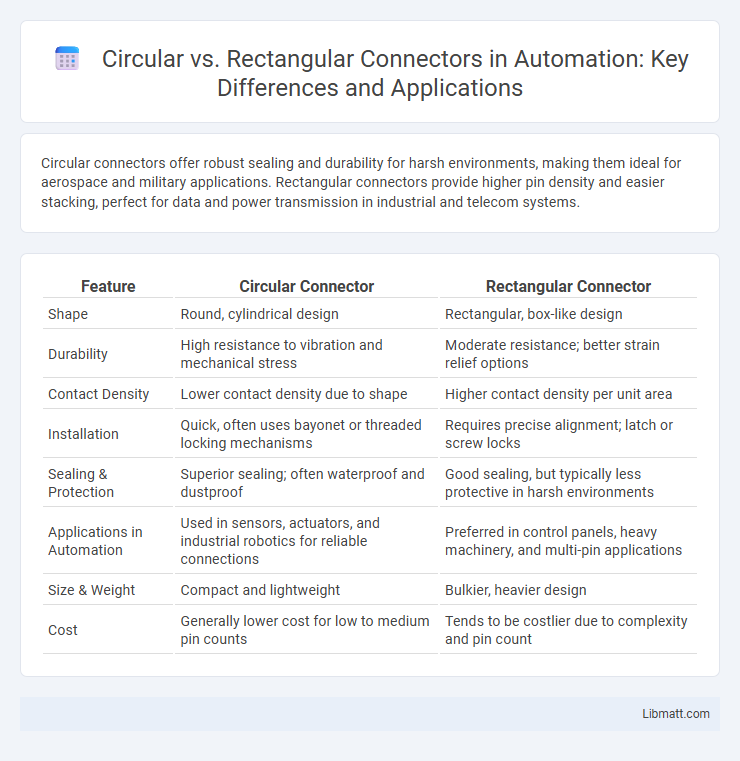

Circular connectors offer robust sealing and durability for harsh environments, making them ideal for aerospace and military applications. Rectangular connectors provide higher pin density and easier stacking, perfect for data and power transmission in industrial and telecom systems.

Table of Comparison

| Feature | Circular Connector | Rectangular Connector |

|---|---|---|

| Shape | Round, cylindrical design | Rectangular, box-like design |

| Durability | High resistance to vibration and mechanical stress | Moderate resistance; better strain relief options |

| Contact Density | Lower contact density due to shape | Higher contact density per unit area |

| Installation | Quick, often uses bayonet or threaded locking mechanisms | Requires precise alignment; latch or screw locks |

| Sealing & Protection | Superior sealing; often waterproof and dustproof | Good sealing, but typically less protective in harsh environments |

| Applications in Automation | Used in sensors, actuators, and industrial robotics for reliable connections | Preferred in control panels, heavy machinery, and multi-pin applications |

| Size & Weight | Compact and lightweight | Bulkier, heavier design |

| Cost | Generally lower cost for low to medium pin counts | Tends to be costlier due to complexity and pin count |

Introduction to Circular and Rectangular Connectors

Circular connectors feature a cylindrical housing with multiple pins arranged in a circular pattern, offering robust connections ideal for harsh environments and applications requiring waterproof or dustproof seals. Rectangular connectors have a box-shaped design with multiple rows of pins, providing high-density contacts for space-efficient wiring in electronic and industrial systems. Both types support diverse electrical and signal transmission needs, with circular connectors excelling in durability and rectangular connectors in compactness and versatility.

Key Differences Between Circular and Rectangular Connectors

Circular connectors offer a more compact, rugged design that excels in harsh environments due to their round shape, which provides enhanced durability and resistance to vibration. Rectangular connectors typically provide higher pin density and easier customization, making them ideal for complex wiring layouts and applications requiring multiple contacts. Your choice depends on whether you need robust environmental protection with circular connectors or flexible design configurations with rectangular connectors.

Design and Construction Comparisons

Circular connectors feature a cylindrical design with a robust metal housing that offers superior sealing and durability in harsh environments, making them ideal for aerospace and military applications. Rectangular connectors have a boxy shape with multiple rows of contacts, allowing for higher pin counts and easy stacking in compact electronic systems. Your choice depends on whether you prioritize environmental protection and ruggedness (circular) or high-density connections and space efficiency (rectangular).

Performance and Reliability Factors

Circular connectors offer superior environmental sealing and durability, making them highly reliable in harsh and high-vibration conditions frequently encountered in aerospace and military applications. Rectangular connectors provide higher contact density and easier panel-mounting options, which enhance performance in space-constrained electronic systems requiring multiple signal types. Both connector types must be selected considering factors like contact resistance, insertion force, and resistance to corrosion to ensure optimum long-term performance.

Application Areas for Circular Connectors

Circular connectors are extensively used in harsh environments such as aerospace, military, and industrial automation due to their robust construction and superior resistance to vibration and moisture. Their compact design and reliable sealing make them ideal for applications in medical devices, transportation systems, and outdoor equipment. Circular connectors also support multi-pin configurations for complex electronic systems requiring secure and efficient signal transmission.

Application Areas for Rectangular Connectors

Rectangular connectors are predominantly used in industrial automation, military, aerospace, and telecommunications due to their robust design and high pin density, which supports complex wiring systems. Their modular configuration allows for easy customization in equipment such as control panels, data centers, and heavy machinery, ensuring reliable performance under harsh environmental conditions. These connectors efficiently manage power, signal, and data transmission, making them ideal for applications requiring durability and scalability.

Advantages of Circular Connectors

Circular connectors offer superior durability and resistance to environmental factors such as moisture, dust, and vibrations, making them ideal for industrial and military applications. Their robust design allows for easy alignment and secure mating, which supports reliable connections even in harsh conditions. The compact and symmetrical form factor also enables versatility in space-constrained installations while maintaining high electrical performance.

Advantages of Rectangular Connectors

Rectangular connectors offer advantages such as higher contact density, allowing more connections within a compact footprint. Their modular design enables easy customization and adaptability for diverse applications in aerospace, military, and industrial environments. Enhanced mechanical stability and robust locking mechanisms provide reliable performance under harsh conditions, making them ideal for heavy-duty and high-vibration scenarios.

Selecting the Right Connector for Your Project

Selecting the right connector for your project involves evaluating the specific requirements for durability, space, and signal types. Circular connectors offer robust sealing, resistance to vibration, and ease of mating in compact spaces, making them ideal for demanding industrial and military applications. Rectangular connectors provide greater pin density and flexibility for complex wiring configurations in telecommunications, data centers, and aerospace systems, ensuring your design meets performance and reliability standards.

Future Trends in Connector Technology

Future trends in connector technology emphasize enhanced durability, miniaturization, and high-speed data transmission for both circular connectors and rectangular connectors. Circular connectors lead in rugged environments due to their sealed design and resistance to harsh conditions, while rectangular connectors excel in applications requiring high density and modularity. Your choice should consider emerging demands for IoT integration, faster communication protocols, and increased mechanical robustness in next-generation connector solutions.

Circular Connector vs Rectangular Connector Infographic

libmatt.com

libmatt.com