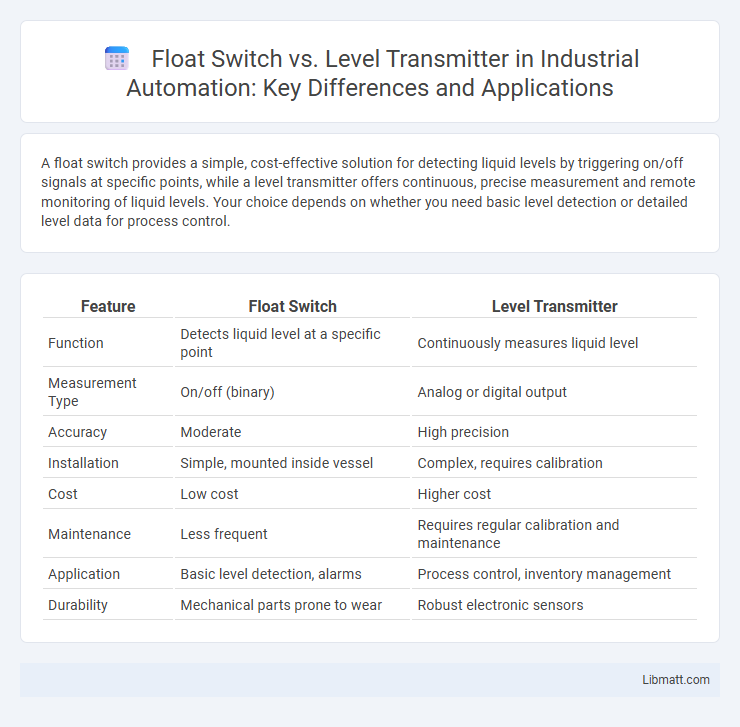

A float switch provides a simple, cost-effective solution for detecting liquid levels by triggering on/off signals at specific points, while a level transmitter offers continuous, precise measurement and remote monitoring of liquid levels. Your choice depends on whether you need basic level detection or detailed level data for process control.

Table of Comparison

| Feature | Float Switch | Level Transmitter |

|---|---|---|

| Function | Detects liquid level at a specific point | Continuously measures liquid level |

| Measurement Type | On/off (binary) | Analog or digital output |

| Accuracy | Moderate | High precision |

| Installation | Simple, mounted inside vessel | Complex, requires calibration |

| Cost | Low cost | Higher cost |

| Maintenance | Less frequent | Requires regular calibration and maintenance |

| Application | Basic level detection, alarms | Process control, inventory management |

| Durability | Mechanical parts prone to wear | Robust electronic sensors |

Introduction to Liquid Level Measurement Technologies

Liquid level measurement technologies include float switches and level transmitters, both critical for monitoring fluid levels in tanks and vessels. Float switches use a buoyant device that moves with the liquid surface to trigger an electrical contact, offering a simple, cost-effective solution for on/off level detection. Level transmitters employ advanced sensors like ultrasonic, radar, or pressure-based instruments to provide continuous, precise liquid level data essential for process control and automation in various industries.

What is a Float Switch?

A float switch is a device used to detect the level of liquid within a tank or container, operating through a buoyant float that rises and falls with the liquid surface. It provides simple, reliable on/off control for pumps, alarms, or valves based on predetermined liquid levels. Your choice of a float switch ensures cost-effective, low-maintenance level monitoring for applications requiring basic liquid detection.

What is a Level Transmitter?

A level transmitter is an advanced sensor device designed to measure the continuous level of liquids, solids, or slurries within a container or tank, providing real-time data for process control. Unlike a float switch that operates on on-off control by detecting specific liquid levels, level transmitters use technologies such as ultrasonic, radar, or pressure sensing for precise and continuous monitoring. Industries such as oil and gas, water treatment, and chemical manufacturing rely on level transmitters for accurate inventory management and safety compliance.

Working Principles: Float Switch vs Level Transmitter

Float switches operate on a mechanical principle where a buoyant float rises or falls with the liquid level, triggering a switch to open or close an electrical circuit. Level transmitters use electronic sensors such as ultrasonic, radar, or capacitive technologies to continuously measure the liquid level and convert it into an electrical signal for precise monitoring and control. The key difference lies in the float switch providing discrete on/off signals, whereas level transmitters offer continuous, real-time level measurements.

Types of Float Switches and Applications

Magnetic float switches typically offer reliable liquid level detection through a float containing a magnet that activates a reed switch, suitable for water tanks and sump pumps. Paddle float switches operate using a rotating vane that senses the liquid level in viscous or slurry conditions, ideal for waste treatment plants. Understanding these types helps you select the appropriate float switch for precise monitoring in industrial, commercial, or residential liquid level control systems.

Types of Level Transmitters and Their Uses

Level transmitters come in various types including ultrasonic, radar, capacitive, and hydrostatic, each designed for specific applications such as measuring liquids, solids, or interface levels. Ultrasonic transmitters are ideal for non-contact measurement in water treatment, while radar transmitters excel in harsh environments with dust or vapor. Your choice between float switches and level transmitters depends on the accuracy, reliability, and environmental conditions required for effective level detection and control.

Accuracy and Reliability Comparison

Float switches provide basic level detection with moderate accuracy suitable for non-critical applications, whereas level transmitters offer precise continuous measurement with higher resolution and consistent reliability in various conditions. Level transmitters use advanced sensor technologies like ultrasonic, radar, or pressure, ensuring minimal drift and real-time data accuracy essential for process control. Float switches are prone to mechanical wear and environmental interference, which can reduce their reliability compared to the robust design and digital outputs of level transmitters.

Installation, Maintenance, and Cost Considerations

Float switches offer simple installation and low upfront cost, with basic maintenance involving periodic cleaning to prevent debris buildup. Level transmitters require more complex installation, often involving wiring and calibration, but provide precise continuous level measurement, which can reduce long-term maintenance efforts through diagnostic features. Your choice depends on budget constraints and the need for accuracy, with float switches being cost-effective for straightforward applications and level transmitters suitable for high-precision, low-maintenance requirements.

Choosing Between a Float Switch and Level Transmitter

Choosing between a float switch and a level transmitter depends on your application's accuracy and monitoring needs. Float switches provide simple, cost-effective on/off liquid level detection ideal for basic control systems, while level transmitters offer continuous, precise level measurement suited for complex industrial processes. Your choice influences system reliability, maintenance frequency, and data accuracy, making it crucial to assess operational requirements before selecting either device.

Summary and Final Recommendations

Float switches provide reliable, cost-effective point-level detection ideal for simple liquid monitoring tasks, while level transmitters offer precise continuous measurement suited for complex process control. Selecting between the two depends on application requirements, budget, and desired accuracy, with float switches favored for basic on/off control and level transmitters for detailed level profiling. For industries demanding high accuracy and integration with automated systems, level transmitters are recommended, whereas float switches remain practical for straightforward, low-cost liquid level detection.

Float Switch vs Level Transmitter Infographic

libmatt.com

libmatt.com