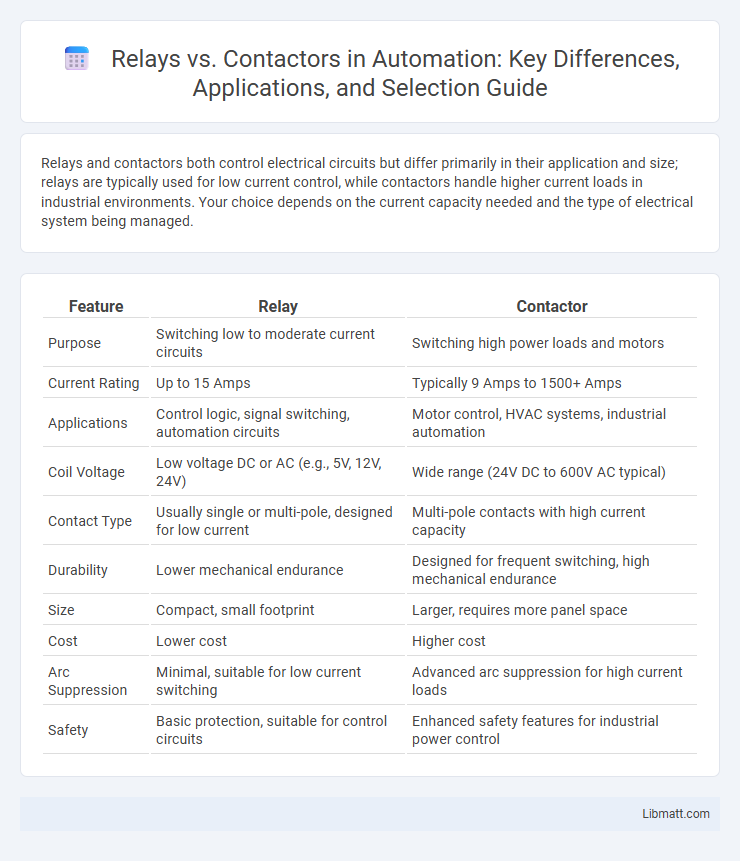

Relays and contactors both control electrical circuits but differ primarily in their application and size; relays are typically used for low current control, while contactors handle higher current loads in industrial environments. Your choice depends on the current capacity needed and the type of electrical system being managed.

Table of Comparison

| Feature | Relay | Contactor |

|---|---|---|

| Purpose | Switching low to moderate current circuits | Switching high power loads and motors |

| Current Rating | Up to 15 Amps | Typically 9 Amps to 1500+ Amps |

| Applications | Control logic, signal switching, automation circuits | Motor control, HVAC systems, industrial automation |

| Coil Voltage | Low voltage DC or AC (e.g., 5V, 12V, 24V) | Wide range (24V DC to 600V AC typical) |

| Contact Type | Usually single or multi-pole, designed for low current | Multi-pole contacts with high current capacity |

| Durability | Lower mechanical endurance | Designed for frequent switching, high mechanical endurance |

| Size | Compact, small footprint | Larger, requires more panel space |

| Cost | Lower cost | Higher cost |

| Arc Suppression | Minimal, suitable for low current switching | Advanced arc suppression for high current loads |

| Safety | Basic protection, suitable for control circuits | Enhanced safety features for industrial power control |

Introduction to Relays and Contactors

Relays and contactors are essential electromechanical switches used to control electrical circuits by opening and closing contacts in response to an electrical signal. Relays typically handle lower current applications and serve as control devices for small loads, while contactors are designed for switching higher power circuits in industrial environments, often controlling motors and heavy machinery. Understanding the differences in voltage ratings, coil types, and load capacities helps optimize your electrical system's efficiency and safety.

Basic Working Principle

Relays and contactors operate by using an electromagnetic coil to open or close electrical contacts, controlling the flow of current in a circuit. A relay is typically designed for low-current applications, switching smaller loads, while a contactor handles higher current loads, often used in industrial motors and heavy machinery control. Your choice between the two depends on the electrical load requirements and the specific control needs of your system.

Key Differences Between Relays and Contactors

Relays and contactors both function as electrically operated switches but differ mainly in their capacity and application. Relays are typically used for low-current circuits up to 10 amps, ideal for signal switching and control tasks, whereas contactors handle high-power loads exceeding 10 amps, commonly found in motor control and industrial machinery. Your choice between them depends on the current rating, voltage level, and the specific demands of your electrical system.

Typical Applications of Relays

Relays are commonly used in low-power applications such as signal switching, automation systems, and control circuits where precise switching of electrical signals is required. They are ideal for applications involving protection circuits, alarm systems, and small motor controls due to their ability to handle low current loads efficiently. In contrast to contactors, relays excel in scenarios demanding electrical isolation and fine control over low-voltage devices.

Common Uses for Contactors

Contactors are primarily used in industrial applications to control electric motors, lighting systems, heating equipment, and capacitor banks. They offer high current switching capabilities and can handle frequent cycling, making them ideal for automation and heavy-duty electrical loads. Common industries utilizing contactors include manufacturing, HVAC, and power distribution.

Voltage and Current Ratings

Relays typically handle lower voltage and current ratings, making them ideal for control signals and small loads, whereas contactors are designed for high voltage and heavy current applications, such as electric motors and industrial equipment. Your choice depends on the specific voltage and current requirements of your system to ensure reliable performance and safety. Contactors often feature ratings exceeding 600V and currents above 100A, while relays generally operate under 30A and lower voltages.

Physical Size and Construction

Relays typically have a compact physical size designed for low-current control circuits, featuring a simple electromagnetic coil and a set of contacts enclosed in a small plastic or metal casing. Contactors are larger, built to handle high-current loads with robust construction including heavy-duty contacts, arc suppression mechanisms, and heat-resistant materials to ensure durability in industrial applications. Their substantial size and solid build accommodate the increased electrical and mechanical stresses encountered during frequent switching of high-power equipment.

Control Circuit Design Considerations

Relays and contactors both play critical roles in control circuit design, with relays typically used for low-current, signal-level switching and contactors designed for high-current power control applications. Your selection depends on factors such as load type, voltage, current ratings, and coil voltage compatibility within the control circuit to ensure safe and efficient operation. Optimizing control circuit design requires evaluating coil power consumption, contact configuration, response time, and environmental conditions to achieve reliable performance.

Advantages and Limitations

Relays offer compact size and are ideal for low-current applications, providing fast switching with minimal power consumption, making them cost-effective for control circuits. Contactors excel in handling high-current loads, delivering robust performance and enhanced durability for industrial motors and heavy electrical equipment. Limitations of relays include lower current capacity and shorter lifespan under heavy loads, while contactors have larger physical sizes and require more power to operate their coils.

How to Choose Between a Relay and a Contactor

Choosing between a relay and a contactor depends primarily on the application's voltage, current requirements, and switching frequency. Relays are ideal for low current control circuits and signal switching, while contactors are designed to handle high power loads such as motors and industrial equipment. Ensure Your selection matches the electrical load characteristics and control needs to optimize performance and safety.

Relays vs Contactors Infographic

libmatt.com

libmatt.com