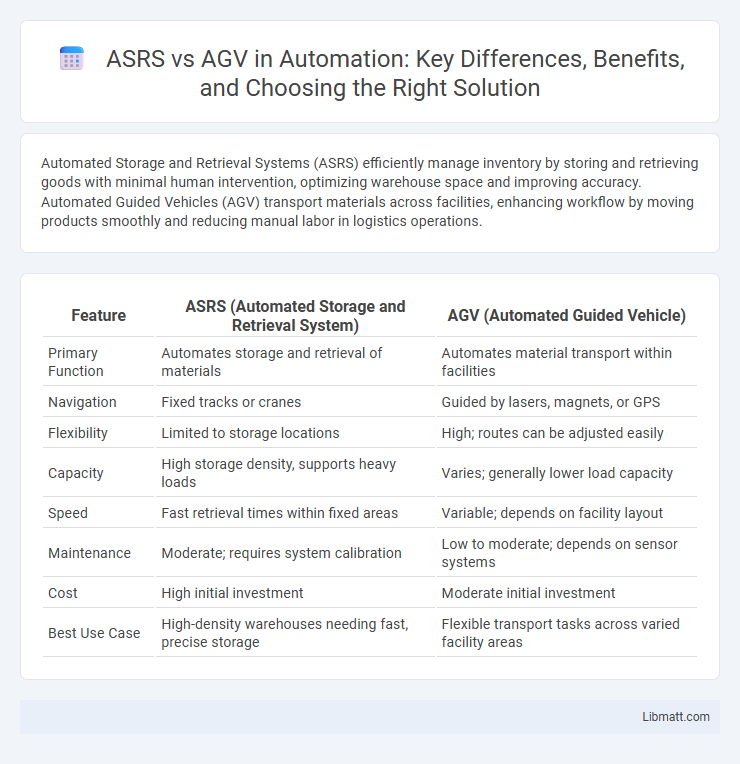

Automated Storage and Retrieval Systems (ASRS) efficiently manage inventory by storing and retrieving goods with minimal human intervention, optimizing warehouse space and improving accuracy. Automated Guided Vehicles (AGV) transport materials across facilities, enhancing workflow by moving products smoothly and reducing manual labor in logistics operations.

Table of Comparison

| Feature | ASRS (Automated Storage and Retrieval System) | AGV (Automated Guided Vehicle) |

|---|---|---|

| Primary Function | Automates storage and retrieval of materials | Automates material transport within facilities |

| Navigation | Fixed tracks or cranes | Guided by lasers, magnets, or GPS |

| Flexibility | Limited to storage locations | High; routes can be adjusted easily |

| Capacity | High storage density, supports heavy loads | Varies; generally lower load capacity |

| Speed | Fast retrieval times within fixed areas | Variable; depends on facility layout |

| Maintenance | Moderate; requires system calibration | Low to moderate; depends on sensor systems |

| Cost | High initial investment | Moderate initial investment |

| Best Use Case | High-density warehouses needing fast, precise storage | Flexible transport tasks across varied facility areas |

Introduction to ASRS and AGV Technologies

Automated Storage and Retrieval Systems (ASRS) are advanced warehouse technologies designed to automatically place and retrieve inventory with high precision, improving storage density and operational efficiency. Automated Guided Vehicles (AGVs) are mobile robots that transport materials across facilities using predefined paths or dynamic navigation systems, enhancing flexibility in material handling. Both ASRS and AGVs integrate sensors, software, and robotics to streamline warehouse automation and optimize supply chain workflows.

Key Differences Between ASRS and AGV

ASRS (Automated Storage and Retrieval Systems) are fixed infrastructure solutions designed for high-density storage, using robotic cranes or shuttles to efficiently manage inventory within warehouses. AGVs (Automated Guided Vehicles) are mobile robots equipped with sensors and navigation systems to transport goods across different facility areas, offering flexibility in movement and tasks. Your choice between ASRS and AGV depends on your operational needs for storage density versus material transport versatility.

Core Components of ASRS Systems

Automated Storage and Retrieval Systems (ASRS) rely on core components such as storage racks, robotic shuttles, cranes, and computer-controlled software for precise inventory management. These elements work together to optimize space utilization, improve warehouse efficiency, and reduce labor costs. Unlike Automated Guided Vehicles (AGVs), which focus on autonomous material transport, ASRS primarily emphasizes automated storage solutions and real-time inventory automation.

Fundamental Features of AGV Solutions

Automated Guided Vehicles (AGVs) are designed with essential features such as autonomous navigation, real-time obstacle detection, and flexible route planning to enhance material handling efficiency within warehouses. These vehicles use sensors, lasers, or magnetic tapes to follow predefined paths, ensuring precise and safe transportation of goods. Your facility benefits from AGVs' scalability and adaptability, which allow seamless integration into existing workflows without the need for extensive infrastructure changes.

Operational Efficiency: ASRS vs AGV

Automated Storage and Retrieval Systems (ASRS) deliver superior operational efficiency through precise inventory management and rapid item retrieval, reducing human error and optimizing warehouse space utilization. Automated Guided Vehicles (AGV) enhance workflow flexibility by transporting goods dynamically across different warehouse zones but may face limitations in storage density and speed compared to ASRS. Your choice depends on whether prioritizing high-density, high-speed storage solutions (ASRS) or adaptable material movement (AGV) aligns better with your operational goals.

Cost Implications: Investing in ASRS or AGV

Investing in ASRS (Automated Storage and Retrieval Systems) often requires a higher upfront capital expenditure due to complex infrastructure and integration costs, but delivers long-term savings through increased storage density and labor reduction. AGVs (Automated Guided Vehicles) typically involve lower initial investment and greater flexibility for material transport but may incur higher operational expenses over time due to maintenance and limited scalability. Your choice between ASRS and AGV should consider total cost of ownership, including installation, maintenance, and potential productivity gains.

Space Utilization and Scalability Comparison

Automated Storage and Retrieval Systems (ASRS) maximize space utilization through dense vertical stacking and precision placement within warehouse aisles, allowing higher inventory density compared to Automated Guided Vehicles (AGV), which require wider pathways for navigation and maneuvering. Scalability of ASRS depends on the integration of modular storage bins and robotic shuttles that can be incrementally added, while AGV scalability involves increasing the fleet size, which may demand additional infrastructure adjustments to prevent traffic congestion. Efficient space use in ASRS supports high-throughput operations, whereas AGVs offer flexible scalability but need careful spatial planning to optimize overall warehouse layout.

Safety and Maintenance Considerations

ASRS (Automated Storage and Retrieval Systems) offer enhanced safety with fixed pathways and controlled environments, reducing the risk of collisions compared to AGVs (Automated Guided Vehicles), which navigate dynamic settings and require more sophisticated obstacle detection systems. Maintenance for ASRS typically involves periodic checks on mechanical components and software updates, while AGVs need regular inspections of navigation sensors, batteries, and drive units to ensure operational reliability. Understanding these safety and maintenance differences helps you optimize system uptime and workforce protection based on your warehouse automation needs.

Ideal Use Cases for ASRS and AGV

Automated Storage and Retrieval Systems (ASRS) excel in high-density warehouse environments where precise inventory management and rapid item retrieval are critical, such as e-commerce fulfillment centers and manufacturing supply chains. Automated Guided Vehicles (AGVs) are ideal for material transport across large facilities or dynamic layouts, supporting just-in-time delivery in automotive plants and distribution centers. Both systems enhance operational efficiency but serve distinct roles: ASRS optimizes vertical storage and rapid access, while AGVs improve horizontal movement and flexibility.

Choosing the Right Solution: ASRS or AGV

Selecting the right solution between Automated Storage and Retrieval Systems (ASRS) and Automated Guided Vehicles (AGV) depends on facility layout, storage density, and operational goals. ASRS excels in maximizing vertical storage space and improving inventory accuracy in high-density warehouses, while AGVs offer flexible material transport and adaptability in dynamic environments. Evaluating factors such as workflow complexity, scalability, and integration with warehouse management systems (WMS) ensures optimal automation investment.

ASRS vs AGV Infographic

libmatt.com

libmatt.com