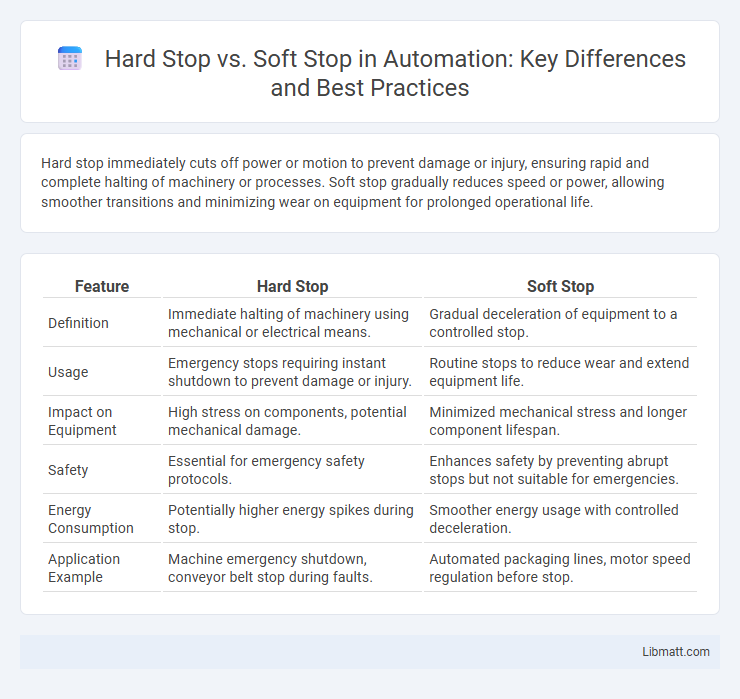

Hard stop immediately cuts off power or motion to prevent damage or injury, ensuring rapid and complete halting of machinery or processes. Soft stop gradually reduces speed or power, allowing smoother transitions and minimizing wear on equipment for prolonged operational life.

Table of Comparison

| Feature | Hard Stop | Soft Stop |

|---|---|---|

| Definition | Immediate halting of machinery using mechanical or electrical means. | Gradual deceleration of equipment to a controlled stop. |

| Usage | Emergency stops requiring instant shutdown to prevent damage or injury. | Routine stops to reduce wear and extend equipment life. |

| Impact on Equipment | High stress on components, potential mechanical damage. | Minimized mechanical stress and longer component lifespan. |

| Safety | Essential for emergency safety protocols. | Enhances safety by preventing abrupt stops but not suitable for emergencies. |

| Energy Consumption | Potentially higher energy spikes during stop. | Smoother energy usage with controlled deceleration. |

| Application Example | Machine emergency shutdown, conveyor belt stop during faults. | Automated packaging lines, motor speed regulation before stop. |

Understanding Hard Stop and Soft Stop

Hard stop refers to a definite, non-negotiable deadline or limit that must be strictly adhered to, often used in project management and scheduling to prevent overruns. Soft stop allows for some flexibility or extension beyond the initial deadline, accommodating unforeseen changes while still aiming to meet the targeted timeframe. Understanding the distinction between hard stop and soft stop is crucial for effective deadline management and balancing strictness with adaptability in time-sensitive tasks.

Key Differences Between Hard Stop and Soft Stop

Hard stop systems abruptly halt motion using mechanical means, ensuring immediate cessation but causing higher wear and potential impact damage. Soft stop mechanisms gradually reduce speed before stopping, enhancing precision and minimizing mechanical stress, ideal for delicate applications. The choice depends on operational requirements for speed, safety, and equipment longevity.

When to Use a Hard Stop

A hard stop is essential in business or project management when deadlines are non-negotiable due to external constraints such as regulatory compliance, contract obligations, or product launch dates tied to market conditions. It ensures all stakeholders understand that no extension is possible, preventing scope creep and maintaining focus on critical milestones. This strict time boundary is crucial for resource allocation, risk management, and maintaining client trust in time-sensitive projects.

Applications of Soft Stop in Industry

Soft stop technology is widely applied in industries requiring precise control and protection of mechanical equipment during shutdown, such as conveyor systems, packaging machines, and heavy-duty presses. It reduces the mechanical stress and wear on components by gradually decreasing the motor speed, extending equipment lifespan and minimizing downtime. Your manufacturing process benefits from enhanced safety, improved product quality, and reduced maintenance costs through the implementation of soft stop systems.

Pros and Cons of Hard Stops

Hard stops provide clear deadlines that drive focused effort and prevent project delays, ensuring timely completion. However, they can create stress and reduce flexibility, potentially impacting creativity and adaptability when unexpected issues arise. Your team benefits from hard stops by maintaining discipline but should balance them with contingencies to avoid compromising quality.

Advantages and Disadvantages of Soft Stops

Soft stops provide the advantage of gentle motion control, reducing mechanical stress and extending the lifespan of equipment by avoiding abrupt halts. They help improve safety by minimizing sudden shocks that could cause injury or damage during operation. However, soft stops may lead to longer stopping distances and potential difficulties in precise positioning, which can be a disadvantage in applications requiring quick or exact stops.

Safety Implications: Hard Stop vs. Soft Stop

Hard stop mechanisms provide immediate cessation of motion, significantly reducing the risk of mechanical overrun and potential injury in industrial machinery. In contrast, soft stop systems gradually decelerate moving parts, enhancing operator safety by minimizing abrupt impacts and mechanical stress. Evaluating safety implications involves balancing the need for rapid halts against the benefits of controlled, smooth stopping to prevent accidents and equipment damage.

Choosing Between Hard Stop and Soft Stop

Choosing between a hard stop and a soft stop depends on your machine's operational requirements and safety standards. A hard stop immediately halts motion for urgent safety or precise positioning, ideal for emergency situations or equipment protection. Soft stops provide controlled deceleration, reducing mechanical stress and prolonging equipment lifespan while maintaining smoother operations.

Industry Examples: Hard Stop vs. Soft Stop

In manufacturing, hard stops are commonly used in CNC machines to prevent over-travel and ensure precision by physically halting movement at a set point, while soft stops utilize sensors and software limits to gradually slow down equipment, enhancing safety in automated assembly lines. In elevator systems, hard stops serve as mechanical barriers to prevent cabins from exceeding designated floors, whereas soft stops rely on electronic controls for smooth deceleration and improved passenger comfort. Your choice between hard stop and soft stop mechanisms impacts operational efficiency, safety standards, and equipment longevity across industries like robotics, automotive, and packaging.

Future Trends in Stop Mechanisms

Future trends in stop mechanisms emphasize the integration of smart technology for enhanced precision and safety. Soft stop systems, utilizing advanced sensors and AI, are expected to dominate industries requiring delicate handling, reducing wear and improving efficiency. You can anticipate increased adoption of hybrid systems combining the rapid response of hard stops with the smooth deceleration of soft stops for optimized performance.

Hard Stop vs Soft Stop Infographic

libmatt.com

libmatt.com