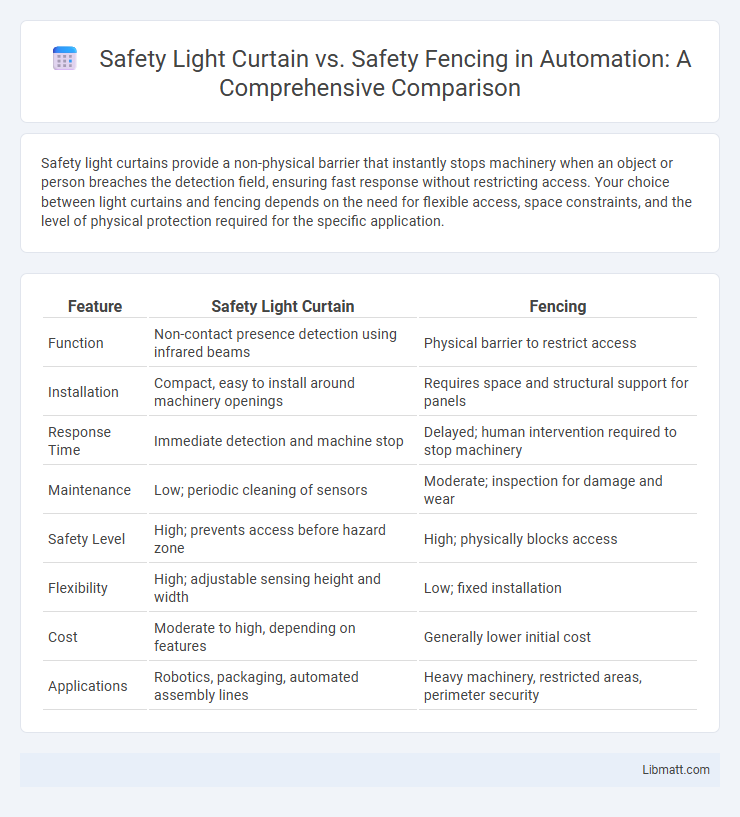

Safety light curtains provide a non-physical barrier that instantly stops machinery when an object or person breaches the detection field, ensuring fast response without restricting access. Your choice between light curtains and fencing depends on the need for flexible access, space constraints, and the level of physical protection required for the specific application.

Table of Comparison

| Feature | Safety Light Curtain | Fencing |

|---|---|---|

| Function | Non-contact presence detection using infrared beams | Physical barrier to restrict access |

| Installation | Compact, easy to install around machinery openings | Requires space and structural support for panels |

| Response Time | Immediate detection and machine stop | Delayed; human intervention required to stop machinery |

| Maintenance | Low; periodic cleaning of sensors | Moderate; inspection for damage and wear |

| Safety Level | High; prevents access before hazard zone | High; physically blocks access |

| Flexibility | High; adjustable sensing height and width | Low; fixed installation |

| Cost | Moderate to high, depending on features | Generally lower initial cost |

| Applications | Robotics, packaging, automated assembly lines | Heavy machinery, restricted areas, perimeter security |

Introduction to Machine Safety: Light Curtain vs Fencing

Machine safety systems are critical for protecting operators from hazardous equipment, with light curtains and fencing being two primary options. Safety light curtains use optoelectronic sensors to create invisible barriers that immediately stop machinery when breached, enhancing accessibility and reducing downtime. In contrast, safety fencing provides a physical barrier that restricts entry to dangerous zones, offering robust protection but often limiting operational flexibility.

How Safety Light Curtains Work

Safety light curtains use infrared beams to create an invisible protective barrier around hazardous machinery, instantly detecting any interruption when an object or person crosses the light path. This triggers an immediate machine stop to prevent injury, ensuring a non-contact safety solution that enhances operational efficiency. Unlike physical fencing, light curtains provide flexible, easy-to-integrate protection suitable for dynamic work environments where quick access is necessary.

Understanding Safety Fencing Systems

Safety fencing systems provide a physical barrier that restricts access to hazardous machine areas, ensuring personnel safety by preventing entry altogether. These systems are designed to withstand mechanical impacts and are typically used in environments where full separation is essential to protect workers from moving machinery. Compared to safety light curtains, fencing offers a more robust, permanent solution for hazard containment but may reduce operational flexibility and access speed.

Key Differences Between Light Curtains and Fencing

Safety light curtains offer non-physical hazard detection by using infrared beams to create an invisible protective barrier, while fencing provides a physical barrier to restrict access to dangerous machinery. Light curtains enable quick access and minimal interference with workflow, whereas fencing requires gates or locks that may slow down operations. The choice between them depends on factors such as space constraints, risk levels, and ease of maintenance for industrial safety compliance.

Installation Requirements: Light Curtains vs Fencing

Safety light curtains require minimal installation space and can be mounted directly on machinery or production lines, offering flexible positioning without extensive structural modifications. In contrast, fencing demands significant floor space, sturdy frames, and secure anchoring to create a physical barrier, often necessitating professional installation and longer set-up times. Your choice depends on available space, installation speed, and the level of physical obstruction needed for your safety system.

Performance and Reliability Comparison

Safety light curtains provide high-performance, non-contact detection of objects, ensuring precise and immediate response to interruptions while maintaining continuous production flow. Safety fencing offers robust physical barriers but can limit accessibility and slower response times due to the need for mechanical interaction. Your choice between the two depends on whether you prioritize fast detection with minimal disruption or strong physical protection for hazardous zones.

Cost Analysis: Investment and Maintenance

Safety light curtains generally involve a lower initial investment compared to traditional fencing due to their simpler installation and adaptability to various machinery layouts. Maintenance costs for light curtains tend to be minimal, primarily requiring periodic cleaning and sensor calibration, whereas fencing systems may incur higher expenses for repairs, repainting, and potential modifications as production needs change. Your choice depends on balancing the upfront savings of light curtains with the durability and protective coverage provided by fencing over time.

Compliance with Safety Standards

Safety light curtains and fencing both comply with stringent safety standards such as ISO 13849 and IEC 61496, ensuring reliable hazard detection and prevention in industrial environments. Light curtains typically offer faster response times and higher sensitivity, meeting Category 4 and PL e requirements for safeguarding machinery access points. Fencing provides robust physical barriers aligned with OSHA and ANSI regulations, ensuring long-term protection and restricted entry but may lack the dynamic response capabilities of electronic light curtains.

Applications and Industry Use Cases

Safety light curtains are ideal for applications requiring fast, non-contact detection in industries like automotive assembly and packaging, where protecting operators from moving machinery is critical. Fencing is commonly used in heavy industries such as metal forging and machining, providing a physical barrier to restrict access to hazardous zones. Your choice depends on the need for rapid access versus strict perimeter control in environments with different safety risk levels.

Choosing the Right Solution for Your Operation

Safety light curtains offer flexible, non-contact protection by creating an invisible sensor barrier that stops machinery when breached, ideal for applications requiring quick access and high productivity. Safety fencing provides a physical, robust barrier to prevent entry into hazardous zones, best suited for environments needing permanent or heavy-duty protection. Evaluating factors such as space constraints, operational speed, maintenance requirements, and risk severity ensures the optimal choice for safeguarding personnel and maintaining workflow efficiency.

Safety Light Curtain vs Fencing Infographic

libmatt.com

libmatt.com