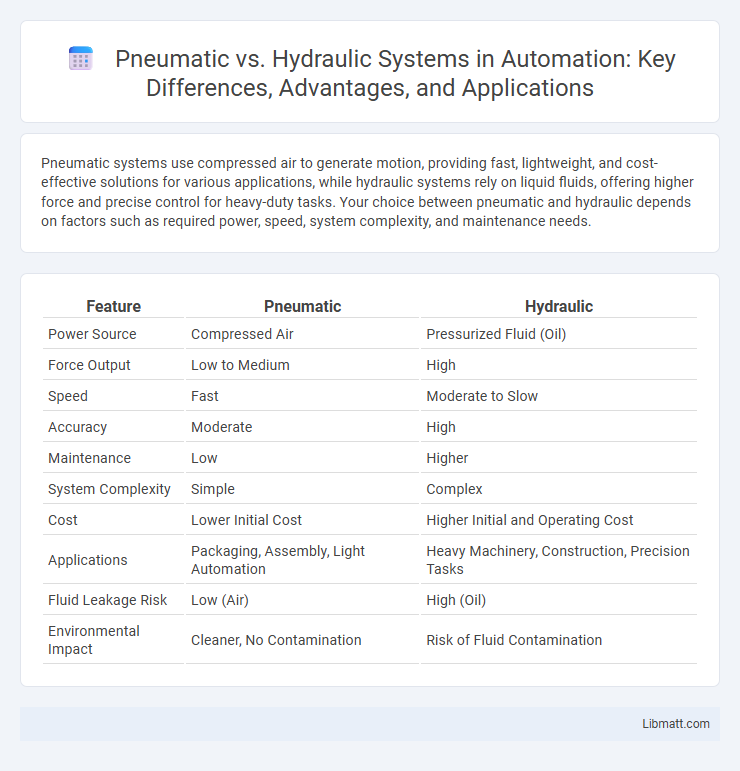

Pneumatic systems use compressed air to generate motion, providing fast, lightweight, and cost-effective solutions for various applications, while hydraulic systems rely on liquid fluids, offering higher force and precise control for heavy-duty tasks. Your choice between pneumatic and hydraulic depends on factors such as required power, speed, system complexity, and maintenance needs.

Table of Comparison

| Feature | Pneumatic | Hydraulic |

|---|---|---|

| Power Source | Compressed Air | Pressurized Fluid (Oil) |

| Force Output | Low to Medium | High |

| Speed | Fast | Moderate to Slow |

| Accuracy | Moderate | High |

| Maintenance | Low | Higher |

| System Complexity | Simple | Complex |

| Cost | Lower Initial Cost | Higher Initial and Operating Cost |

| Applications | Packaging, Assembly, Light Automation | Heavy Machinery, Construction, Precision Tasks |

| Fluid Leakage Risk | Low (Air) | High (Oil) |

| Environmental Impact | Cleaner, No Contamination | Risk of Fluid Contamination |

Introduction to Pneumatic and Hydraulic Systems

Pneumatic systems use compressed air to generate mechanical motion, making them ideal for applications requiring speed and simplicity with lightweight components. Hydraulic systems rely on pressurized fluid, typically oil, to deliver high force and precise control in heavy-duty industrial machinery. Your choice between pneumatic and hydraulic systems depends on factors such as required power, control accuracy, and environmental conditions.

Fundamental Principles: How Pneumatic and Hydraulic Systems Work

Pneumatic systems operate using compressed air to transmit and control energy through pressurized gas, making them ideal for lighter, faster applications with cleaner operation. Hydraulic systems use incompressible liquid, typically oil, to generate powerful, precise force and movement in heavy-duty machinery and industrial equipment. Both systems rely on fluid power principles but differ in fluid type, pressure ranges, and typical use cases, influencing their performance and application environments.

Key Components of Pneumatic vs Hydraulic Systems

Pneumatic systems primarily consist of compressors, air tanks, valves, actuators, and air filters that manage compressed air to generate motion or force. Hydraulic systems feature pumps, hydraulic fluid reservoirs, valves, actuators, and cylinders, using pressurized liquid to transfer energy efficiently. The choice between pneumatic and hydraulic components depends on factors like required force, precision, system speed, and environmental conditions.

Efficiency and Performance Comparison

Hydraulic systems deliver higher efficiency and greater power density than pneumatic systems, making them ideal for heavy-duty applications requiring precise control and consistent force. Pneumatic systems, while less efficient due to compressible air, offer faster response times and cleaner operation, suitable for lightweight or high-speed tasks. Your choice depends on the required performance, with hydraulics excelling in strength and precision and pneumatics favored for speed and simplicity.

Energy Consumption and Power Output

Pneumatic systems consume less energy for low to moderate power applications due to the compressibility of air, resulting in some energy loss during expansion. Hydraulic systems deliver higher power output and efficiency, offering precise control and consistent force by using incompressible fluids, making them ideal for heavy-duty tasks. Your choice depends on balancing energy efficiency with the required power output for optimal performance.

Application Areas: Where Pneumatic or Hydraulic Systems Excel

Pneumatic systems excel in applications requiring rapid movement and clean operation, such as packaging, automation, and small tool actuation in industries like food processing and electronics. Hydraulic systems are ideal for heavy-duty applications demanding high force and precise control, including construction equipment, aircraft control systems, and industrial machinery. Both systems offer distinct advantages tailored to specific operational needs, with pneumatics favoring speed and cleanliness and hydraulics emphasizing power and precision.

Maintenance and Operational Costs

Pneumatic systems typically have lower maintenance and operational costs due to simpler components and the use of compressed air, which is readily available and clean. Hydraulic systems require more frequent maintenance because of fluid leaks, contamination risks, and the need for specialized hydraulic fluids, increasing operational expenses. In industrial applications, pneumatic systems are favored for cost efficiency, while hydraulics are preferred for high-force requirements despite higher maintenance costs.

Safety and Environmental Considerations

Pneumatic systems are generally safer than hydraulic systems due to their use of compressed air, which poses less risk of fire and toxic leaks compared to hydraulic fluids. Hydraulic systems require careful maintenance to prevent fluid leaks that can cause environmental contamination and slippery work conditions. You should assess the specific risks and environmental impacts of each system based on your operational context to ensure compliance with safety regulations and minimize ecological harm.

Advantages and Disadvantages Overview

Pneumatic systems offer the advantages of faster movement, cleaner operation due to the use of compressed air, and lower initial costs, making them ideal for applications requiring speed and simplicity. Hydraulic systems provide higher power density, precise control, and greater force output, suited for heavy-duty tasks but involve complexities like fluid leakage and higher maintenance costs. You should consider pneumatic systems for lighter, faster operations while hydraulic systems excel where high force and precision are critical.

Choosing the Right System: Decision-Making Factors

Selecting between pneumatic and hydraulic systems depends on key factors such as required force, precision, and operating environment. Pneumatic systems are ideal for applications needing fast, lightweight, and clean operations with moderate force, while hydraulic systems excel in high-force, precise control tasks under heavy loads. Consider pressure levels, fluid type, maintenance demands, and cost-effectiveness to determine the optimal system for specific industrial applications.

Pneumatic vs Hydraulic Infographic

libmatt.com

libmatt.com