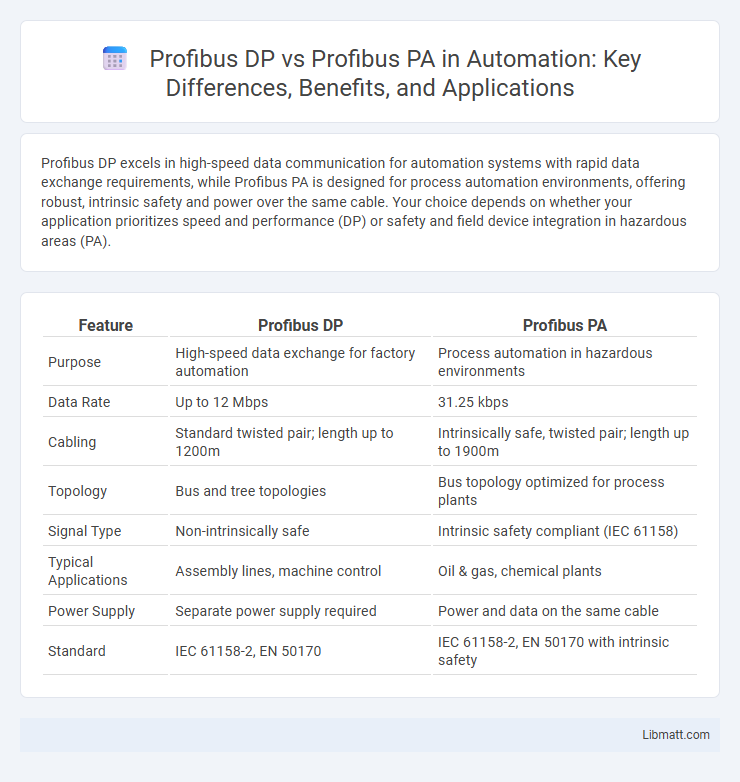

Profibus DP excels in high-speed data communication for automation systems with rapid data exchange requirements, while Profibus PA is designed for process automation environments, offering robust, intrinsic safety and power over the same cable. Your choice depends on whether your application prioritizes speed and performance (DP) or safety and field device integration in hazardous areas (PA).

Table of Comparison

| Feature | Profibus DP | Profibus PA |

|---|---|---|

| Purpose | High-speed data exchange for factory automation | Process automation in hazardous environments |

| Data Rate | Up to 12 Mbps | 31.25 kbps |

| Cabling | Standard twisted pair; length up to 1200m | Intrinsically safe, twisted pair; length up to 1900m |

| Topology | Bus and tree topologies | Bus topology optimized for process plants |

| Signal Type | Non-intrinsically safe | Intrinsic safety compliant (IEC 61158) |

| Typical Applications | Assembly lines, machine control | Oil & gas, chemical plants |

| Power Supply | Separate power supply required | Power and data on the same cable |

| Standard | IEC 61158-2, EN 50170 | IEC 61158-2, EN 50170 with intrinsic safety |

Introduction to Profibus DP and Profibus PA

Profibus DP (Decentralized Peripherals) is designed for high-speed communication between automation systems and distributed I/O devices, making it ideal for factory automation with rapid data exchange requirements. Profibus PA (Process Automation) is tailored for process industries, offering robust, intrinsically safe communication that supports field devices in hazardous environments. Your choice between Profibus DP and PA will depend on the specific application needs, such as speed, safety requirements, and environmental conditions.

Overview of Profibus Protocols

Profibus DP (Decentralized Peripherals) is designed for fast communication between automation systems and distributed I/O devices, optimized for speed and real-time data exchange in factory automation. Profibus PA (Process Automation) supports intrinsic safety and is tailored for process industry applications, enabling reliable data transfer in hazardous environments with extended cable distances. Your choice between Profibus DP and PA depends on the application requirements for speed, environment, and device compatibility within industrial networks.

Key Differences Between Profibus DP and Profibus PA

Profibus DP operates at higher speeds up to 12 Mbps and is primarily used for fast communication between automation systems and distributed I/O devices in manufacturing environments. Profibus PA supports lower speeds of 31.25 kbps and is specifically designed for process automation with intrinsic safety features enabling use in hazardous environments. The main differences lie in data transmission rates, application areas, and physical layer specifications tailored to industrial automation and process control needs.

Network Architecture Comparison

Profibus DP utilizes a high-speed, cyclic communication protocol designed for fast data exchange between controllers and decentralized devices, employing a single twisted-pair cable with RS-485 electrical standards optimized for factory automation networks. In contrast, Profibus PA operates at a lower speed with intrinsic safety measures, using a two-wire bus that supplies both data and power, tailored for process automation environments with hazardous conditions. The network architecture of Profibus DP supports star and line topologies with repeaters for extended distances, while Profibus PA relies on a trunk-and-spur topology to facilitate device integration in complex process plants.

Communication Speed and Data Transmission

Profibus DP (Decentralized Peripherals) offers high-speed communication up to 12 Mbps, ideal for rapid data transmission in factory automation and time-critical applications. Profibus PA (Process Automation) operates at a lower speed of 31.25 kbps, optimized for process control environments where intrinsic safety and reliable long-distance communication are essential. Your choice depends on whether fast data exchange or safe, stable transmission in hazardous areas is the priority.

Device Compatibility and Integration

Profibus DP supports high-speed communication for automation devices like sensors, actuators, and PLCs primarily used in factory settings, ensuring seamless integration with general industrial equipment. Profibus PA is designed specifically for process automation, enabling communication with field devices such as transmitters and analyzers in hazardous environments, utilizing intrinsic safety standards. Both protocols allow device compatibility through a common communication profile, but Profibus PA incorporates physical layer modifications for enhanced device integration in process plants.

Application Areas for Profibus DP and PA

Profibus DP (Decentralized Peripherals) is primarily utilized in factory automation for high-speed communication between controllers and decentralized devices such as sensors and actuators, enabling efficient process control and production monitoring. Profibus PA (Process Automation) is designed for hazardous environments in process industries like chemical, oil, and gas, providing reliable data transmission and power supply over the same two-wire cable in intrinsically safe conditions. These distinct application areas highlight Profibus DP's emphasis on speed and Profibus PA's focus on safety and robustness in process automation.

Installation and Cabling Requirements

Profibus DP utilizes standard RS-485 twisted-pair cabling with a maximum segment length of 1,200 meters, supporting fast data transmission rates up to 12 Mbps, ideal for connecting devices in factory automation environments. Profibus PA requires specialized intrinsically safe cables compliant with IEC 61158-2 standards, allowing communication and power over a single two-wire cable with a maximum segment length of 1,900 meters, suited for hazardous process automation zones. The distinct cabling and installation requirements ensure Profibus DP is optimized for speed and flexibility, while Profibus PA prioritizes safety and reliability in explosive atmospheres.

Diagnostic and Maintenance Features

Profibus DP offers advanced diagnostic and maintenance features, enabling real-time monitoring and quick fault detection to minimize downtime in high-speed automation environments. Profibus PA includes intrinsic safety functionality and is optimized for process automation, providing detailed device diagnostics and simplified maintenance in hazardous areas. You can leverage Profibus DP for rapid diagnostics in manufacturing, while Profibus PA ensures continuous monitoring and reliable maintenance in process industries.

Choosing the Right Profibus Technology for Your Application

Profibus DP excels in high-speed data communication for automation systems, making it ideal for fast and efficient device control in manufacturing environments. Profibus PA is specifically designed for process automation, offering intrinsic safety and reliable operation in hazardous areas with extended cable lengths. Understanding the specific requirements of your application, including speed, safety, and environmental conditions, is crucial for selecting the right Profibus technology to optimize performance and reliability.

Profibus DP vs Profibus PA Infographic

libmatt.com

libmatt.com