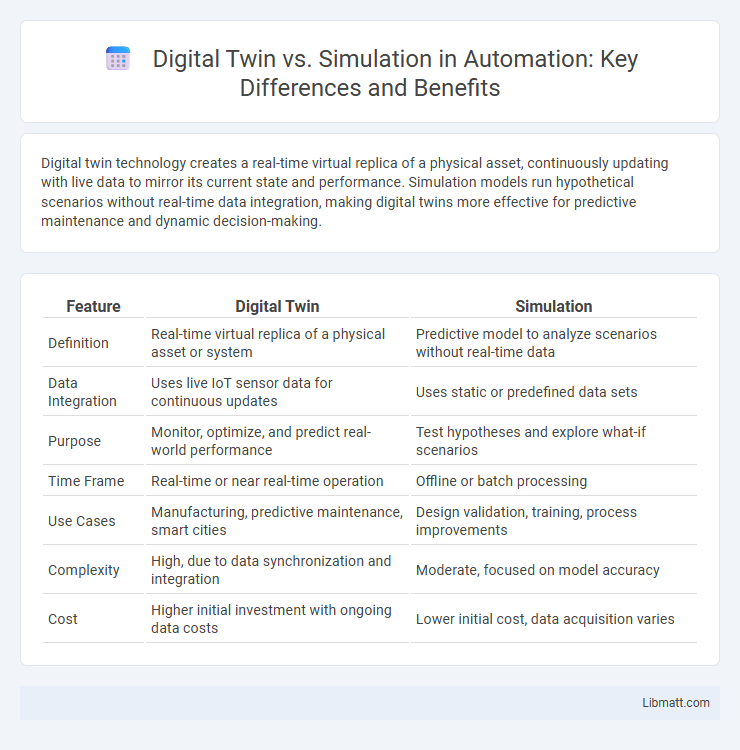

Digital twin technology creates a real-time virtual replica of a physical asset, continuously updating with live data to mirror its current state and performance. Simulation models run hypothetical scenarios without real-time data integration, making digital twins more effective for predictive maintenance and dynamic decision-making.

Table of Comparison

| Feature | Digital Twin | Simulation |

|---|---|---|

| Definition | Real-time virtual replica of a physical asset or system | Predictive model to analyze scenarios without real-time data |

| Data Integration | Uses live IoT sensor data for continuous updates | Uses static or predefined data sets |

| Purpose | Monitor, optimize, and predict real-world performance | Test hypotheses and explore what-if scenarios |

| Time Frame | Real-time or near real-time operation | Offline or batch processing |

| Use Cases | Manufacturing, predictive maintenance, smart cities | Design validation, training, process improvements |

| Complexity | High, due to data synchronization and integration | Moderate, focused on model accuracy |

| Cost | Higher initial investment with ongoing data costs | Lower initial cost, data acquisition varies |

Introduction to Digital Twin and Simulation

Digital Twin technology creates a real-time, virtual replica of a physical asset, enabling continuous monitoring and predictive maintenance. Simulation models replicate processes or systems for specific scenarios, often without live data integration. Your choice depends on whether you need dynamic, real-time insights from a Digital Twin or scenario testing through Simulation.

Defining Digital Twin Technology

Digital Twin technology involves creating a highly accurate, real-time digital replica of physical assets, processes, or systems, enabling continuous monitoring and predictive analysis. Unlike traditional simulations that model hypothetical scenarios based on fixed parameters, Digital Twins integrate live data from IoT sensors and operational systems for dynamic, ongoing synchronization with their physical counterparts. This capability allows businesses to optimize performance, detect anomalies early, and test real-world changes virtually before implementation.

Understanding Simulation Models

Simulation models replicate real-world processes by using mathematical algorithms to predict system behavior under various scenarios, enabling performance analysis and decision-making. Digital twins extend simulation models by creating dynamic, real-time replicas synchronized with physical assets through continuous data integration. This connectivity allows digital twins to provide more accurate, up-to-date insights compared to traditional simulation models, which rely on static or less frequently updated data.

Key Differences Between Digital Twin and Simulation

Digital Twin offers a real-time, dynamic replica of a physical asset or system by continuously integrating live data, whereas simulation provides a static model used to predict outcomes under predefined scenarios. Digital Twin enables ongoing monitoring and predictive maintenance by reflecting actual conditions, while simulation primarily supports analysis and testing without real-time feedback. This makes Digital Twin essential for operational decision-making, whereas simulation is ideal for design validation and hypothetical experimentation.

Core Components of Digital Twins

Digital Twins integrate core components such as real-time data acquisition, advanced analytics, and synchronized virtual replicas of physical assets to provide continuous feedback and operational insights. Unlike traditional simulations, which model scenarios based on static data, Digital Twins enable dynamic interaction and predictive maintenance by mirroring actual system behavior through IoT sensors and AI algorithms. Your ability to optimize performance and reduce downtime relies on the seamless connection between physical components and their digital counterparts, making the core components essential for effective asset management.

Real-Time Data Integration in Digital Twins

Digital Twins utilize real-time data integration to create dynamic, continuously updated virtual models that reflect the current state of physical assets or systems. Unlike traditional simulations, which rely on static input data for scenario analysis, Digital Twins enable ongoing monitoring and predictive analytics by synchronizing with live sensor data. This real-time connectivity allows your organization to optimize performance, detect anomalies early, and make informed decisions based on up-to-date operational insights.

Use Cases: Digital Twin vs Simulation

Digital Twins enable real-time monitoring and predictive maintenance for complex systems such as manufacturing plants, smart grids, and urban infrastructure, providing continuous data integration from physical assets. Simulations are primarily used for scenario testing, design validation, and training in industries like aerospace, automotive, and healthcare, where controlled environment modeling is critical. Your choice depends on whether you need dynamic system replication with live data (Digital Twin) or static scenario analysis without real-time inputs (Simulation).

Advantages and Limitations

Digital twins offer real-time data integration and continuous system monitoring, enabling proactive maintenance and enhanced operational efficiency compared to traditional simulations that rely on static models. Simulations are advantageous for scenario testing and predictive analysis without dependencies on real-time data but lack the dynamic adaptability of digital twins. Limitations of digital twins include high implementation costs and data security concerns, while simulations may provide less accurate results due to simplified or outdated assumptions.

Industry Applications: Which to Choose?

Digital Twin technology offers real-time data integration and dynamic system replication, making it ideal for continuous monitoring and predictive maintenance in manufacturing, smart cities, and aerospace industries. Simulation provides controlled environment testing for scenario analysis and design validation, commonly used in automotive crash tests, healthcare interventions, and energy system modeling. Choosing between Digital Twin and Simulation depends on the need for real-time operational insights versus isolated experimental analysis within industry applications.

Future Trends in Digital Twin and Simulation Technologies

Future trends in digital twin and simulation technologies emphasize increased integration with artificial intelligence, enabling real-time data analysis and predictive maintenance for smarter decision-making. Advances in IoT connectivity and edge computing allow more accurate and dynamic digital representations of physical assets, enhancing operational efficiency across industries. Your business can leverage these innovations to create adaptive, scalable models that evolve with changing conditions, driving innovation and competitive advantage.

Digital Twin vs Simulation Infographic

libmatt.com

libmatt.com