Enclosed panels provide enhanced protection for electrical components by surrounding them with a secure casing, reducing exposure to dust, moisture, and accidental contact. Your choice between enclosed and open panels depends on the environment and safety requirements, with open panels offering easier access for maintenance but less protection.

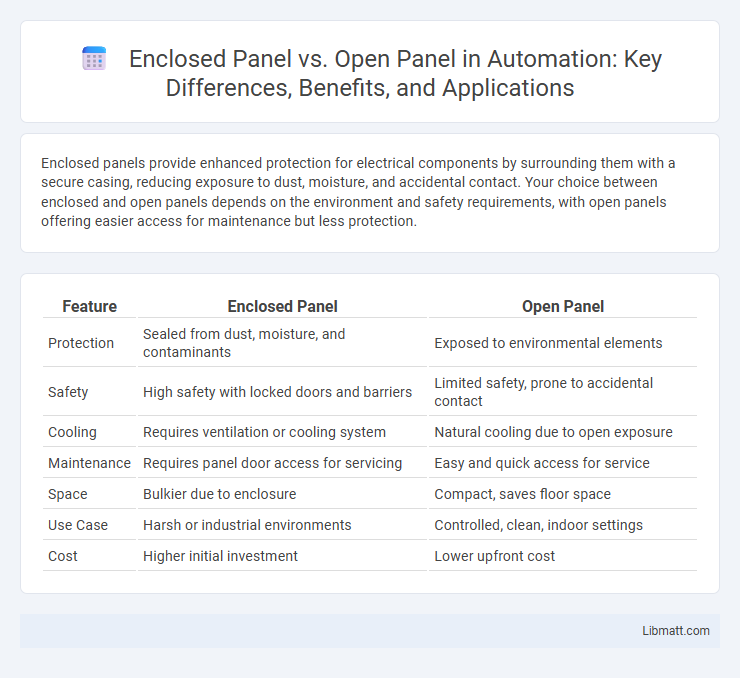

Table of Comparison

| Feature | Enclosed Panel | Open Panel |

|---|---|---|

| Protection | Sealed from dust, moisture, and contaminants | Exposed to environmental elements |

| Safety | High safety with locked doors and barriers | Limited safety, prone to accidental contact |

| Cooling | Requires ventilation or cooling system | Natural cooling due to open exposure |

| Maintenance | Requires panel door access for servicing | Easy and quick access for service |

| Space | Bulkier due to enclosure | Compact, saves floor space |

| Use Case | Harsh or industrial environments | Controlled, clean, indoor settings |

| Cost | Higher initial investment | Lower upfront cost |

Introduction to Enclosed and Open Panels

Enclosed panels protect electrical components with a solid casing, offering enhanced safety and environmental protection against dust, moisture, and physical damage. Open panels expose internal wiring and devices for easy access and ventilation but require strict safety measures to prevent accidental contact or contamination. Your choice between enclosed and open panels depends on factors like installation environment, safety requirements, and maintenance preferences.

Key Differences Between Enclosed and Open Panels

Enclosed panels protect electrical components within a sealed housing, offering superior protection against dust, moisture, and accidental contact, making them ideal for harsh industrial environments. Open panels, on the other hand, have exposed components that allow for easier access and cooling but require controlled environments to prevent damage. Choosing between enclosed and open panels depends on your facility's environmental conditions and maintenance accessibility needs.

Advantages of Enclosed Panels

Enclosed panels offer superior protection against environmental factors such as dust, moisture, and physical damage, ensuring enhanced durability and reliability of electrical components. These panels provide better safety by preventing accidental contact with live parts, reducing the risk of electrical shock or short circuits. Your equipment benefits from reduced maintenance needs and extended lifespan due to the controlled enclosure environment.

Benefits of Open Panel Systems

Open panel systems offer superior flexibility and ease of access, allowing technicians to efficiently perform maintenance and upgrades without disruption. Their design enhances ventilation, reducing the risk of overheating and improving the longevity of electrical components. You benefit from cost savings and simplified troubleshooting with the open panel's straightforward layout.

Applications best Suited for Enclosed Panels

Enclosed panels are ideal for applications requiring protection from dust, moisture, and contaminants, such as industrial automation, manufacturing plants, and outdoor electrical installations. Their sealed design ensures reliability and safety in harsh environments, preventing equipment damage and reducing maintenance needs. If your operation demands durability and environmental resistance, enclosed panels offer a secure solution for sensitive controls and components.

Ideal Uses for Open Panels

Open panels are ideal for facilitating easy access to electrical components in industrial and commercial settings where frequent maintenance, inspection, or adjustments are required. Their design promotes superior ventilation, reducing overheating risks in environments with high heat dissipation needs. You benefit from open panels in applications such as motor control centers, manufacturing plants, and data centers where flexibility and rapid serviceability are critical.

Safety Considerations: Enclosed vs Open Panels

Enclosed panels provide enhanced safety by fully insulating electrical components, reducing the risk of accidental contact and exposure to live wires. Open panels, while offering easier access for maintenance, require strict adherence to safety protocols and protective barriers to prevent electrical hazards. Proper labeling, grounding, and routine inspections are critical in both panel types to ensure compliance with OSHA and NFPA 70E standards.

Cost Comparison: Enclosed and Open Panel Solutions

Enclosed panels typically incur higher initial costs due to their robust protective casing, which safeguards sensitive components from environmental factors, reducing long-term maintenance expenses. Open panels offer a more cost-effective upfront solution by minimizing material usage, but they may lead to increased operational costs from potential damage and contamination. Evaluating total cost of ownership reveals that enclosed panels often provide better value in harsh environments despite their higher upfront investment.

Installation and Maintenance Factors

Enclosed panels offer superior protection against dust, moisture, and physical damage, simplifying maintenance by reducing the frequency of cleaning and component replacements. Open panels provide easier access for installation and troubleshooting, allowing technicians to quickly reach components without removing enclosure covers. Choosing between enclosed and open panels depends on the environment and maintenance priorities, with enclosed panels preferred for harsh or dirty conditions and open panels favored in controlled environments requiring frequent adjustments.

Choosing the Right Panel for Your Project

Choosing the right panel for your project depends on environmental factors and protection requirements. Enclosed panels offer superior protection against dust, moisture, and physical damage, making them ideal for harsh or outdoor conditions. Open panels provide better ventilation and easier access for maintenance, suitable for controlled indoor environments where heat dissipation is a priority.

Enclosed Panel vs Open Panel Infographic

libmatt.com

libmatt.com