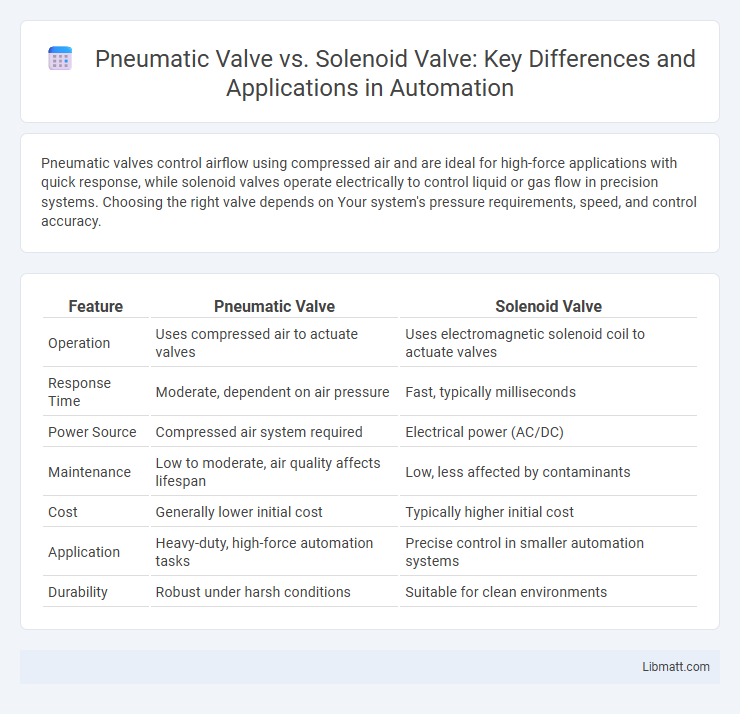

Pneumatic valves control airflow using compressed air and are ideal for high-force applications with quick response, while solenoid valves operate electrically to control liquid or gas flow in precision systems. Choosing the right valve depends on Your system's pressure requirements, speed, and control accuracy.

Table of Comparison

| Feature | Pneumatic Valve | Solenoid Valve |

|---|---|---|

| Operation | Uses compressed air to actuate valves | Uses electromagnetic solenoid coil to actuate valves |

| Response Time | Moderate, dependent on air pressure | Fast, typically milliseconds |

| Power Source | Compressed air system required | Electrical power (AC/DC) |

| Maintenance | Low to moderate, air quality affects lifespan | Low, less affected by contaminants |

| Cost | Generally lower initial cost | Typically higher initial cost |

| Application | Heavy-duty, high-force automation tasks | Precise control in smaller automation systems |

| Durability | Robust under harsh conditions | Suitable for clean environments |

Introduction to Pneumatic and Solenoid Valves

Pneumatic valves control the flow of compressed air in automated systems, commonly used in industrial applications requiring rapid and precise actuation. Solenoid valves operate using an electromagnetic coil to open or close fluid passages, ideal for controlling liquids and gases with electrical signals. Your choice depends on factors like response time, medium compatibility, and power source availability.

Basic Working Principles

Pneumatic valves operate by using compressed air to control the flow and direction of air or gas in a system, relying on mechanical or pilot-operated mechanisms to shift valve positions. Solenoid valves function electrically, using an electromagnetic solenoid coil to move a plunger that opens or closes the valve, enabling precise control of fluid or gas flow. Pneumatic valves are commonly used for high-speed, high-force applications, whereas solenoid valves offer faster response times and are suited for automated systems with electrical control.

Key Design Differences

Pneumatic valves control airflow through mechanical movement powered by compressed air, featuring simple designs with fewer electronic components, which enhance durability in harsh environments. Solenoid valves use electromagnetic coils to actuate valve movement, allowing faster response times and precise control in automated systems. Your choice depends on application requirements such as speed, control accuracy, and environmental conditions.

Applications in Industry

Pneumatic valves excel in industries requiring fast, reliable control of compressed air, such as manufacturing automation, packaging, and material handling systems. Solenoid valves are preferred in applications demanding precise fluid control and integration with electrical systems, including HVAC, water treatment, and chemical processing industries. Your choice depends on whether you need control of air flow or liquid media, balancing speed, precision, and power source requirements.

Performance and Efficiency Comparison

Pneumatic valves offer faster response times and higher durability in continuous-duty applications, making them ideal for heavy-duty industrial use. Solenoid valves provide precise control with lower energy consumption, enhancing efficiency in systems requiring quick actuation and frequent switching. Efficiency in pneumatic valves depends on compressed air supply quality, while solenoid valves excel in minimizing power loss due to direct electrical operation.

Installation and Maintenance Requirements

Pneumatic valves require compressed air systems and more complex piping during installation, leading to higher initial setup costs and space considerations. Solenoid valves offer simpler electrical connections, enabling quicker and more compact installations ideal for automated systems. Your choice depends on maintenance preferences; pneumatic valves need regular air quality checks and lubrication, while solenoid valves demand less frequent servicing but require careful monitoring of electrical components to prevent coil burnout.

Cost Considerations

Pneumatic valves typically have lower initial costs and are more economical for high-flow, high-cycle applications due to their simple design and durable construction. Solenoid valves, while often more expensive upfront, offer precise electronic control and reduced maintenance costs over time, making them suitable for automated systems requiring rapid response. Your choice should balance upfront investment with long-term operational expenses based on system demands and application requirements.

Control and Automation Capabilities

Pneumatic valves offer robust control in high-pressure environments, providing reliable actuation through compressed air, ideal for heavy-duty automation systems requiring stable and precise movement. Solenoid valves excel in fast, electrical switching capabilities that enable seamless integration with digital control systems, enhancing your automation efficiency with rapid response times and easy programmability. Selecting the right valve depends on factors like system pressure, control speed, and automation complexity to optimize performance in your specific application.

Safety and Reliability Aspects

Pneumatic valves offer enhanced safety in hazardous environments due to their non-electrical operation, reducing the risk of sparks or explosions, and provide reliable performance under extreme temperature and pressure conditions. Solenoid valves deliver precise control with rapid response times but may face reliability challenges in high-temperature or corrosive settings, leading to potential coil failures or leakage. Selecting between pneumatic and solenoid valves hinges on the specific application's safety requirements and operational durability, where pneumatic valves excel in safety-critical contexts and solenoid valves suit low-risk, high-precision tasks.

How to Choose the Right Valve for Your Application

Choosing the right valve for your application depends on factors such as pressure requirements, response time, control precision, and operating environment. Pneumatic valves excel in high-flow, high-pressure systems with rapid cycling and minimal electrical hazards, while solenoid valves offer precise electronic control and are suitable for low to medium pressure applications. Evaluate parameters like fluid type, valve size, actuation speed, and system compatibility to determine the most efficient and reliable valve solution.

Pneumatic Valve vs Solenoid Valve Infographic

libmatt.com

libmatt.com