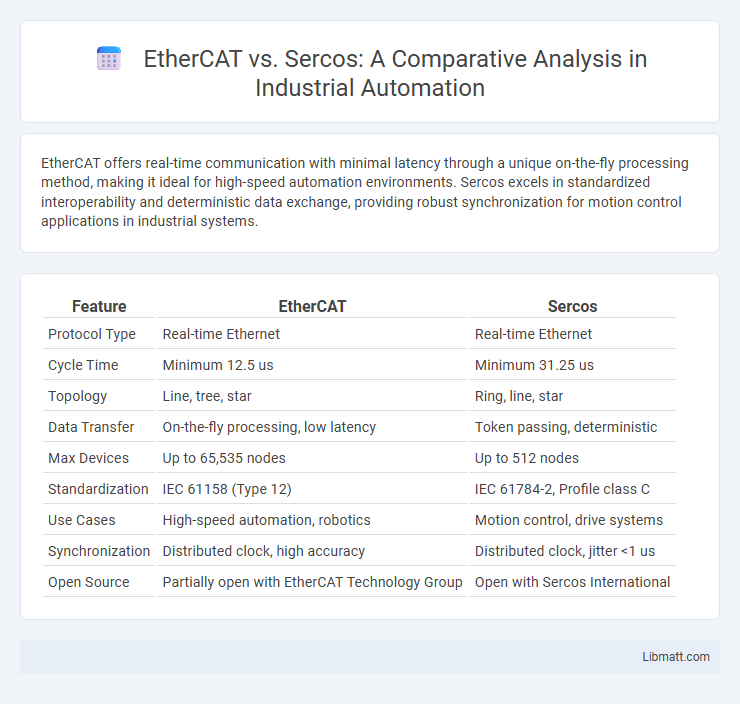

EtherCAT offers real-time communication with minimal latency through a unique on-the-fly processing method, making it ideal for high-speed automation environments. Sercos excels in standardized interoperability and deterministic data exchange, providing robust synchronization for motion control applications in industrial systems.

Table of Comparison

| Feature | EtherCAT | Sercos |

|---|---|---|

| Protocol Type | Real-time Ethernet | Real-time Ethernet |

| Cycle Time | Minimum 12.5 us | Minimum 31.25 us |

| Topology | Line, tree, star | Ring, line, star |

| Data Transfer | On-the-fly processing, low latency | Token passing, deterministic |

| Max Devices | Up to 65,535 nodes | Up to 512 nodes |

| Standardization | IEC 61158 (Type 12) | IEC 61784-2, Profile class C |

| Use Cases | High-speed automation, robotics | Motion control, drive systems |

| Synchronization | Distributed clock, high accuracy | Distributed clock, jitter <1 us |

| Open Source | Partially open with EtherCAT Technology Group | Open with Sercos International |

Introduction to EtherCAT and Sercos

EtherCAT (Ethernet for Control Automation Technology) offers high-speed, real-time communication optimized for industrial automation, ensuring precise synchronization and low latency. Sercos (Serial Real-time Communication System) is a widely adopted open standard designed for motion control applications, delivering deterministic data exchange and interoperability across diverse devices. Your choice between EtherCAT and Sercos depends on system requirements for speed, scalability, and device compatibility in automation networks.

Technology Overview: EtherCAT vs Sercos

EtherCAT employs a high-speed, on-the-fly processing technology that allows data packets to be processed as they pass through each device, minimizing latency and maximizing efficiency in industrial automation networks. Sercos relies on a time-synchronized, deterministic cycle-based communication protocol designed to ensure precise data exchange and real-time control, particularly in motion control applications. Your choice between EtherCAT and Sercos should consider EtherCAT's flexibility and scalability versus Sercos' strong focus on synchronization and safety features in complex automation systems.

Communication Protocols: Key Differences

EtherCAT uses a master-slave communication protocol with a unique on-the-fly processing technique allowing data to be processed as it passes through each node, resulting in extremely low latency and high synchronization accuracy. Sercos operates with a ring topology using time-slot communication to ensure deterministic cyclic data exchange with redundancy for increased reliability. Your choice between EtherCAT and Sercos should consider EtherCAT's efficiency and scalability versus Sercos' robust real-time communication and fault tolerance capabilities.

Network Topologies and Scalability

EtherCAT supports flexible network topologies including line, tree, and star configurations, enabling easy scalability from small to large automation systems. Sercos primarily utilizes ring and line topologies, which provide redundancy but may limit complex expansions. Your choice between EtherCAT and Sercos should consider the specific scalability needs and desired network architecture complexity.

Performance: Speed, Latency, and Determinism

EtherCAT delivers exceptional performance with speeds up to 100 Mbps and ultra-low latency, enabling real-time control in industrial automation environments. Sercos offers comparable deterministic communication with cycle times as low as 31.25 us, supporting high-precision synchronization of motion devices. Your choice depends on system requirements, where EtherCAT excels in speed and scalability, while Sercos provides robust determinism for tightly coordinated motion control.

Interoperability and Compatibility

EtherCAT offers extensive interoperability with a wide range of industrial devices due to its open standard and broad vendor support, enabling seamless integration into diverse automation systems. Sercos, while providing robust real-time communication, maintains strict compatibility within its ecosystem, often requiring specialized hardware or certified devices to ensure optimal performance. Your choice between EtherCAT and Sercos should consider the level of device compatibility and ecosystem openness needed for your automation projects.

Integration with Industrial Automation Systems

EtherCAT offers seamless integration with a wide range of industrial automation systems due to its standardized Ethernet-based protocol, enabling high-speed data exchange and real-time communication essential for complex control architectures. Sercos, known for its deterministic performance, integrates efficiently with motion control and CNC systems, leveraging standardized interfaces for precise synchronization across drive and automation components. Both protocols support interoperability with major automation platforms, but EtherCAT's widespread adoption and open technology provide greater flexibility in heterogeneous industrial environments.

Safety and Security Features

EtherCAT offers built-in safety protocols such as FSoE (Functional Safety over EtherCAT), ensuring real-time safety communication compliant with IEC 61508 standards. Sercos integrates CIP Safety support, enabling secure and deterministic safety data transmission aligned with industry safety requirements. Your choice impacts the level of deterministic safety communication and compliance needed for industrial automation systems.

Typical Applications and Use Cases

EtherCAT excels in high-speed industrial automation tasks such as robotics, CNC machines, and packaging systems due to its low latency and precise synchronization capabilities. Sercos is preferred in motion control applications like servo drives and printing presses, offering real-time deterministic communication and seamless integration with drive technologies. Both protocols support complex automation networks, but EtherCAT is favored for large-scale distributed systems, while Sercos is optimized for tightly coupled drive control environments.

Future Trends and Industry Adoption

EtherCAT continues to dominate industrial automation with faster real-time performance and increasing support for Industry 4.0 applications, positioning it as a preferred choice for high-speed, synchronized control networks. Sercos maintains strong adoption in motion control and robotics due to its deterministic communication and comprehensive safety protocols, with ongoing advancements integrating Ethernet/IP and TSN (Time-Sensitive Networking) standards. Your future-proof automation projects will benefit from evaluating EtherCAT's expanding ecosystem and Sercos' robust interoperability in evolving industrial environments.

EtherCAT vs Sercos Infographic

libmatt.com

libmatt.com